Automatic crystal removing structure of tunnel drainage pipeline and tunnel drainage system with same

A technology for tunnel drainage and crystalline structure, which is applied in the directions of drainage, cleaning methods and utensils, cleaning hollow objects, etc., to reduce the phenomenon of water seepage and water leakage, the structure is simple, and the effect of crystallization is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

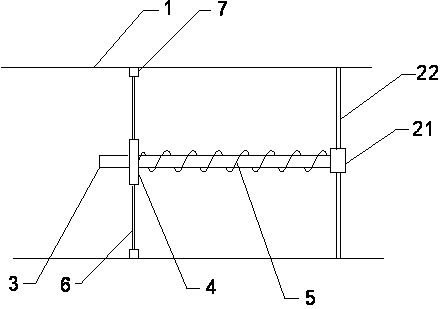

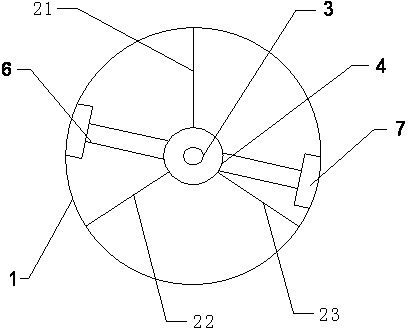

[0015] a kind of like figure 1 and figure 2 The tunnel drainage pipe automatic decrystallization structure shown includes a drainage pipe 1, and a base 2 fixedly connected to it is provided in the drainage pipe 1, and the base 2 includes a baffle 21 and a first fixing rod arranged around the baffle 22. The second fixed rod 23 and the third fixed rod 24, the first fixed rod 22, the second fixed rod 23, and the third fixed rod 24 are located on the same section of the drain pipe 1, and form an angle of 120° between them, A screw shaft 3 is arranged on the blocking plate 21 in the middle of the base 2, and the screw shaft 3 is arranged along the length direction of the drain pipe 1, and a force-receiving piece 4 is movable on the screw shaft 3, and An elastic member 5 is provided between the force-bearing piece 4 and the blocking piece 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com