Gas-liquid stirring and mixing device of urea solution metering injection system

An injection system, gas-liquid mixing technology, applied in the direction of exhaust devices, silencers, mechanical equipment, etc., can solve problems affecting the work of the injection system, deposition crystallization, injection pipeline blockage, etc., to avoid blocking the air inlet, stirring and mixing Good effect, the effect of solving the problem of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

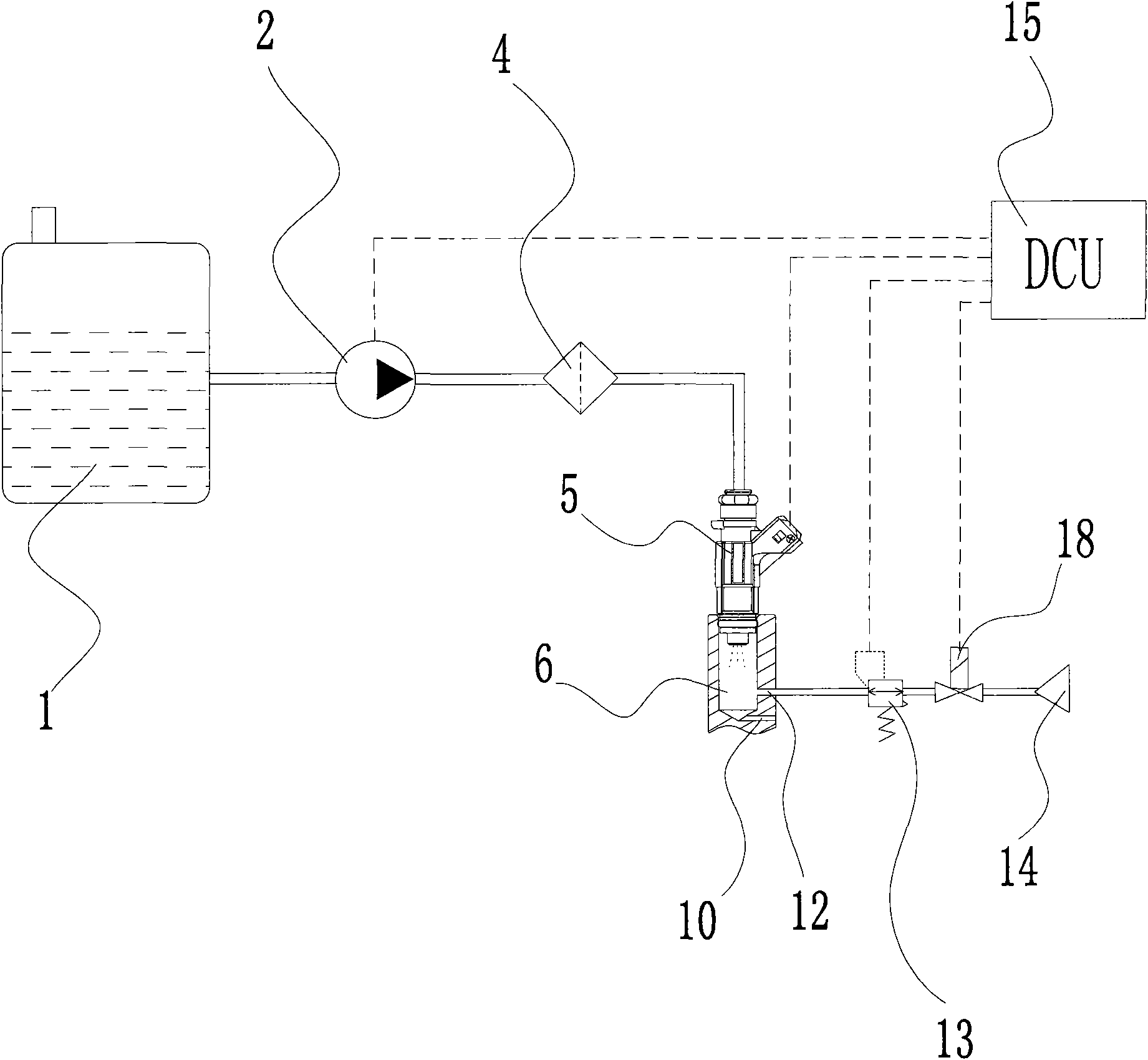

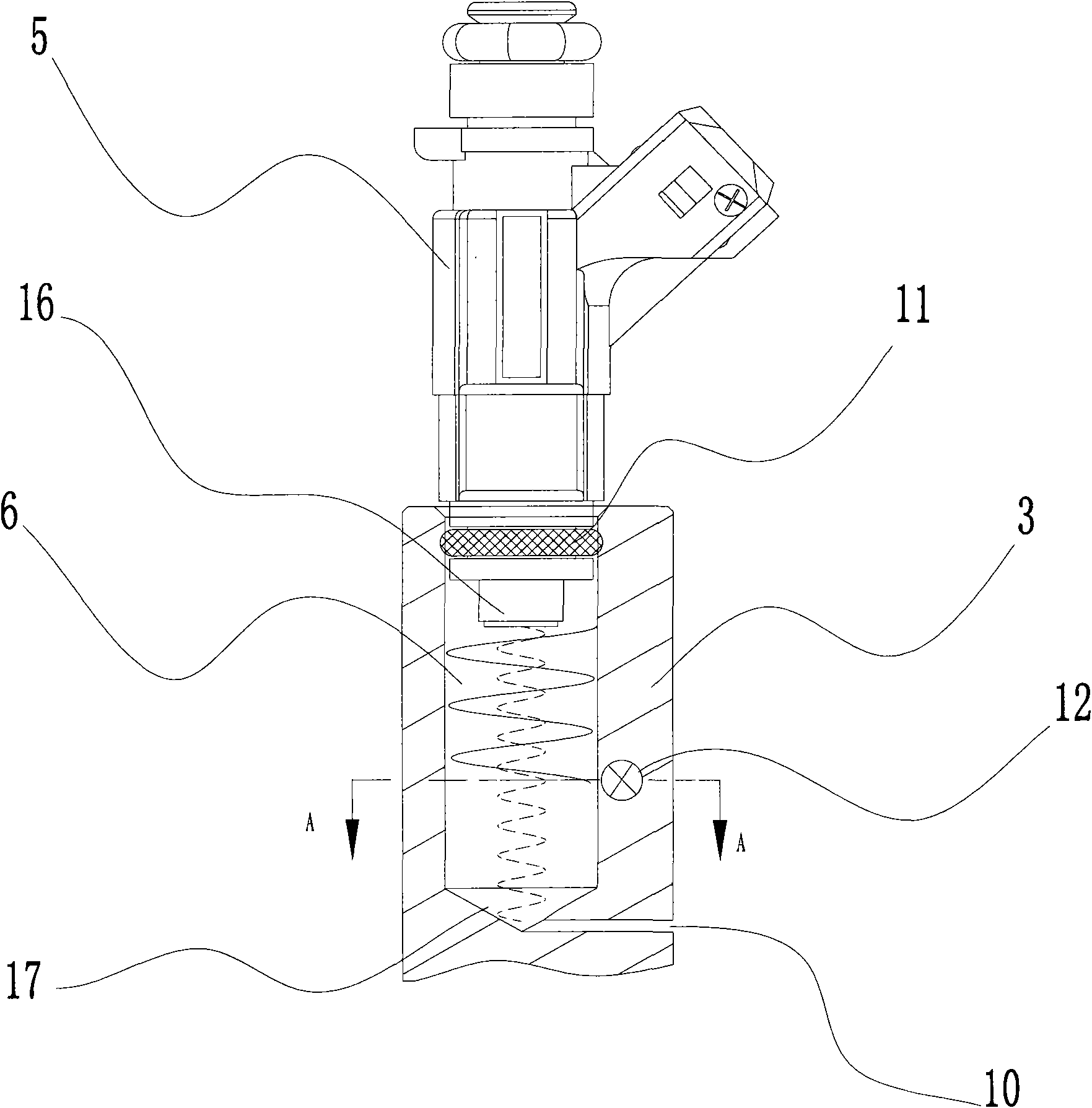

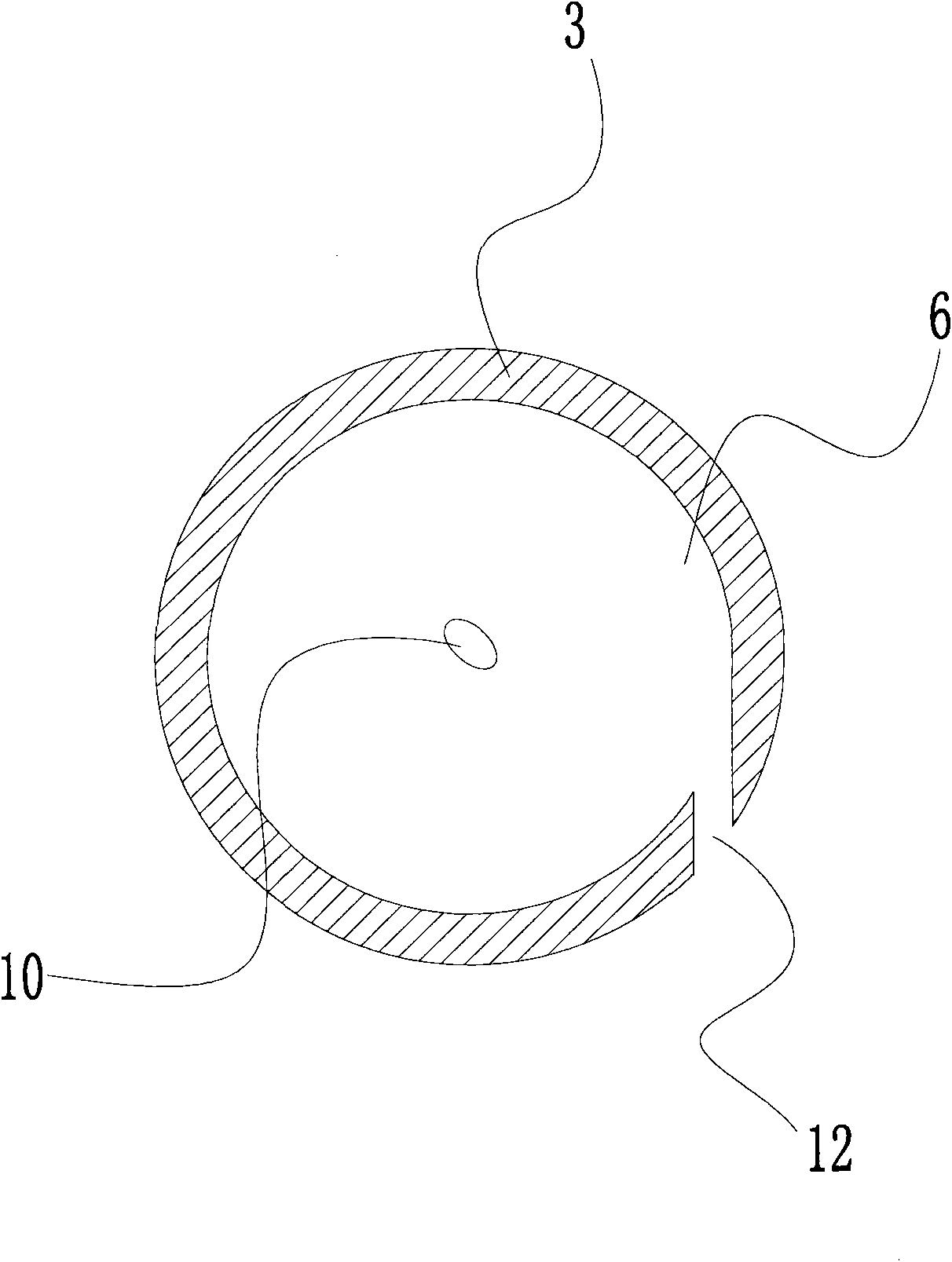

[0018] Such as figure 1 , figure 2 As shown, the purification system using the present invention mainly includes a liquid storage tank 1, a pumping element 2, a filter regulator 4, a metering valve 5 and a mixing chamber 6. The device 4, the metering valve 5 and the mixing chamber 6 are connected in series with pipelines. There is a reducing agent (aqueous urea solution) in the liquid storage tank. The pumping element 2 pumps the reducing agent into the metering valve 5 through the pipeline. The filter 4 pairs The reducing agent plays the role of filtering and stabilizing the pressure. The metering valve 5 performs metered injection of the reducing agent, and the compressed air 6 in the mixing chamber stirs and mixes the injected reducing agent, and blows it to the nozzle in the form of a suspension (not shown in the figure). ), and spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com