Method for cleanly producing lactic acid by fermentation method

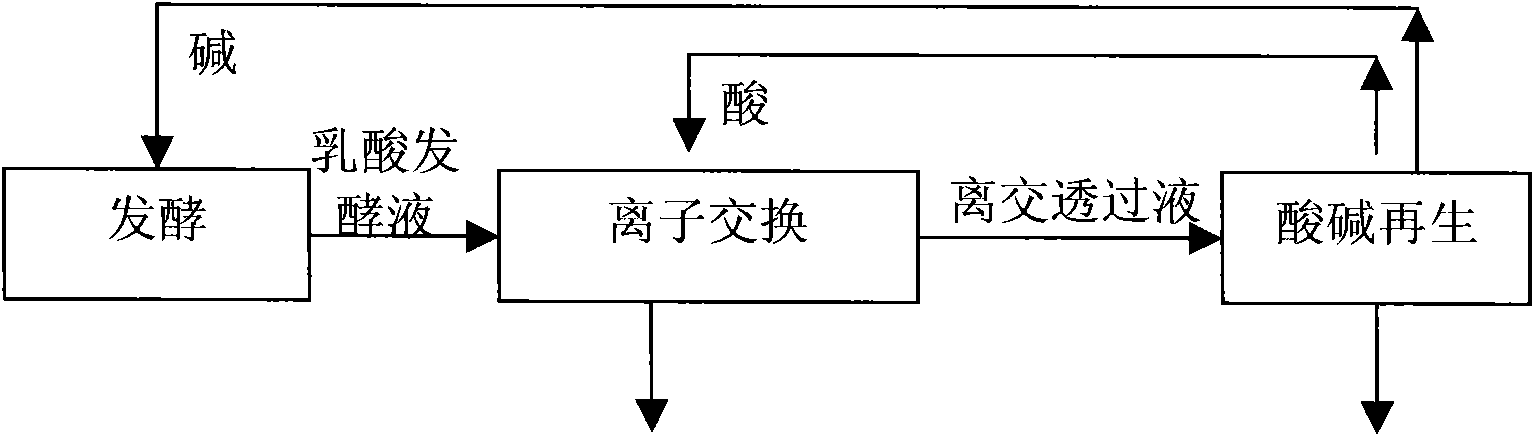

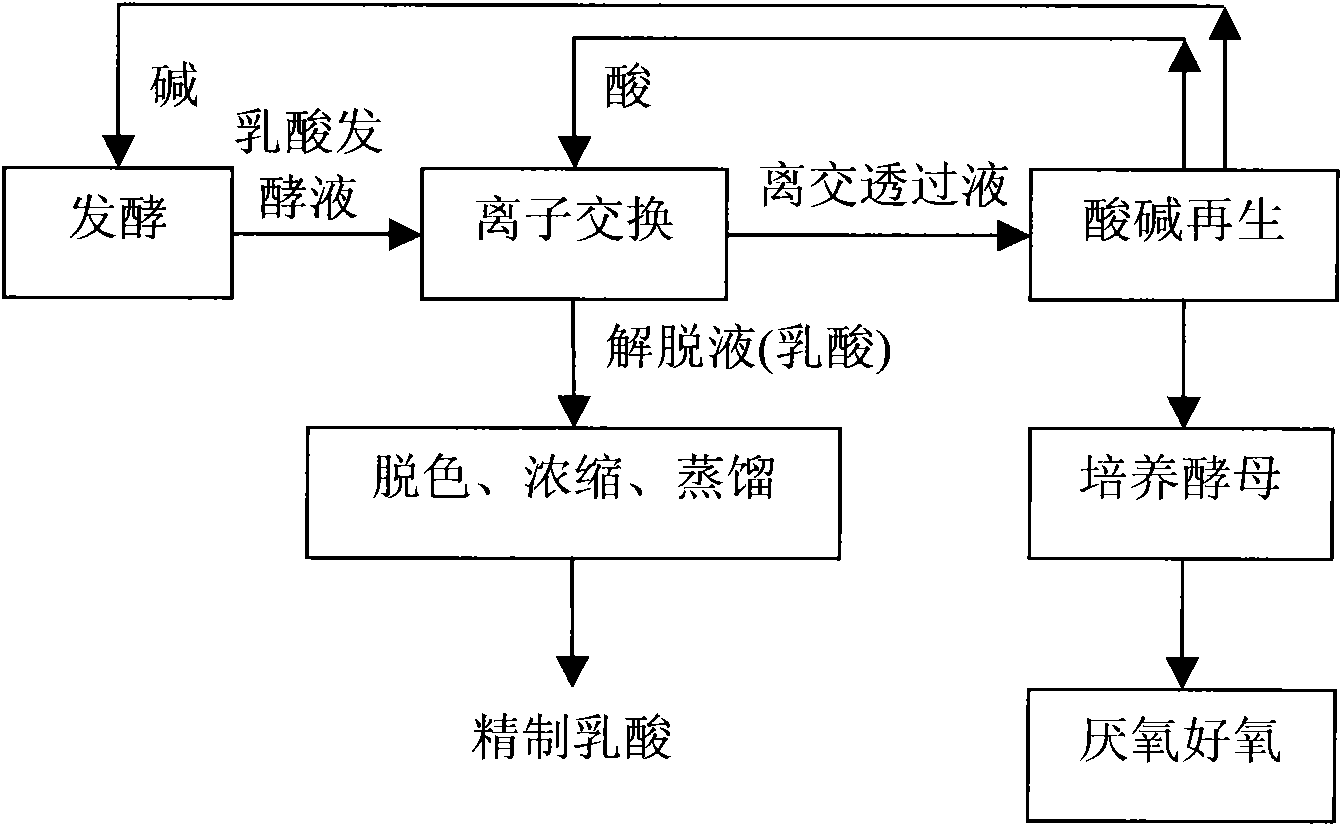

A clean production and fermentation technology, applied in fermentation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of calcium sulfate waste residue, salty waste liquid, etc., to solve pollution problems, speed up, The effect of increasing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Step 1) preparing lactic acid fermentation broth, wherein the pH value of the fermentation broth is adjusted with ammonia water.

[0102] The microbial strain used was Lactobacillus paracasei (Lactobacillus paracasei, NERCB0401 (Industrial Microbiology, 2007, Vol. 37, Issue 4, 1-5)), and fed-batch fermentation was carried out with the above strain. There are two types of media used:

[0103] (1) Seed medium: glucose 40g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, diammonium hydrogen citrate 2g / L, sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L L, Tween 801mL / L, magnesium sulfate 0.6g / L, manganese sulfate 0.25g / L.

[0104] (2) Fermentation medium: glucose 60g / L, peptone 10g / L, beef extract 6g / L, yeast powder 10g / L, sodium chloride 0.03g / L, ferrous sulfate 0.01g / L, sodium acetate 4g / L , diamine citrate 2g / L, potassium dihydrogen phosphate 2g / L, Tween-801mL / L, magnesium sulfate 0.2g / L, manganese sulfate 0.2g / L.

[0105] Prepare two kinds of medium ...

Embodiment 2

[0116] Step 1) is the same as step 1) of Example 1 to prepare a lactic acid fermentation broth to obtain about 3.4 liters of a lactic acid fermentation broth with a lactic acid concentration of 142 g / L.

[0117] Step 2) The ion-exchange column is the same as step 2) of Example 1, wherein the D290 anion-exchange resin packed is converted into sulfate radical type in advance. 2.3 liters of the lactic acid fermented liquid obtained in step 1) are passed through the ion exchange column, so that the lactic acid radical in the lactic acid fermented liquid is replaced by SO 4 2- exchange adsorption. The upper column flow rate is 1.0 column volume / hour, and about 2.2L of ionized permeate containing 0.75mol / L ammonium sulfate is collected at the bottom of the column. The measured pH is 5.9, COD is 25300mg / L, and the calcium and magnesium content is about 200mg / L. L.

[0118] Step 3) Elution of lactic acid

[0119] Use about 0.9mol / L of sulfuric acid to elute step 2) the ion exchang...

Embodiment 3

[0124] Step 1) is the same as step 1) of Example 1 to prepare a lactic acid fermentation broth to obtain about 3.5 liters of a lactic acid fermentation broth with a lactic acid concentration of 142 g / L.

[0125] Step 2) The ion-exchange column is the same as step 2) of Example 1, wherein the D290 anion-exchange resin packed is converted into the nitrate radical type in advance. Pass 2.4 liters of the lactic acid fermentation liquid obtained in step 1) through the ion exchange column, so that the lactic acid radicals in the lactic acid fermentation liquid are covered by NO 3 - exchange adsorption. The upper column flow rate is 1.0 column volume / hour, and about 2.2L of ionized permeate containing 1.5mol / L ammonium nitrate is collected at the bottom of the column. The pH is 5.8, the COD is 24500mg / L, and the calcium and magnesium content is about 200mg / L. L.

[0126] Step 3) Elution of lactic acid

[0127] Use about 2.0mol / L of nitric acid to elute step 2) The ion exchange co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com