Urea solution supply system

A solution supply and urea technology, applied in exhaust gas treatment, machine/engine, mechanical equipment, etc., can solve the problems of necessary compressed air source, poor resistance to impurities, easy urea crystallization, etc., to improve efficiency and reduce pump failure. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

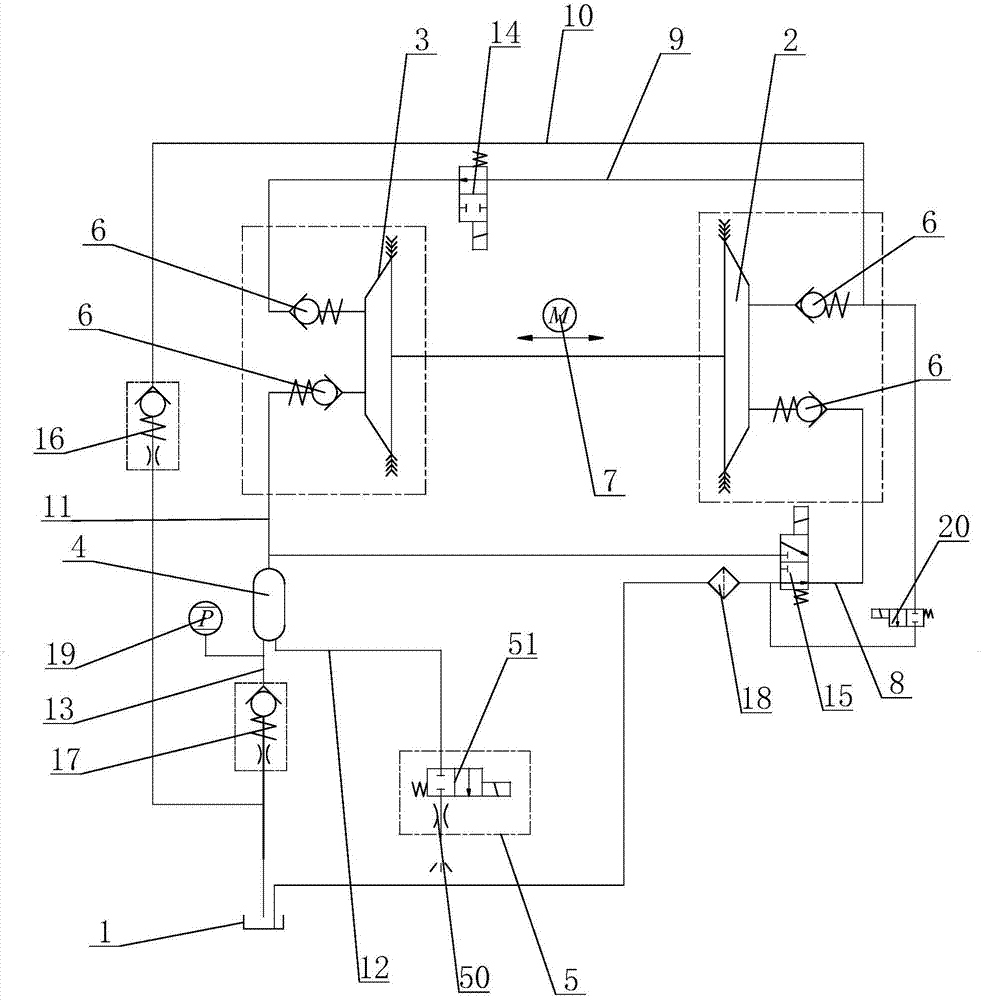

[0021] see figure 1 as shown, figure 1 It is a schematic structural diagram of the urea solution supply system provided in Embodiment 1 of the present invention.

[0022] In this embodiment, a urea solution supply system includes a urea tank 1, a first diaphragm pump 2, a second diaphragm pump 3, an accumulator 4 and a nozzle module 5 connected by pipelines, the first diaphragm pump 2 and A distribution valve 6 is installed on the pipelines of the liquid inlet end and the liquid outlet end of the second diaphragm pump 3, so that the diaphragm pump can only pump the solution in one direction to prevent backflow. Moreover, the first diaphragm pump 2 and the second diaphragm pump 3 are driven by the same motor 7, which can fully and effectively utilize the output torque of the motor, improve the efficiency of the entire diaphragm pump, reduce energy consumption, and reduce costs. There is a 180° phase difference between the first diaphragm pump 2 and the second diaphragm pump 3...

Embodiment 2

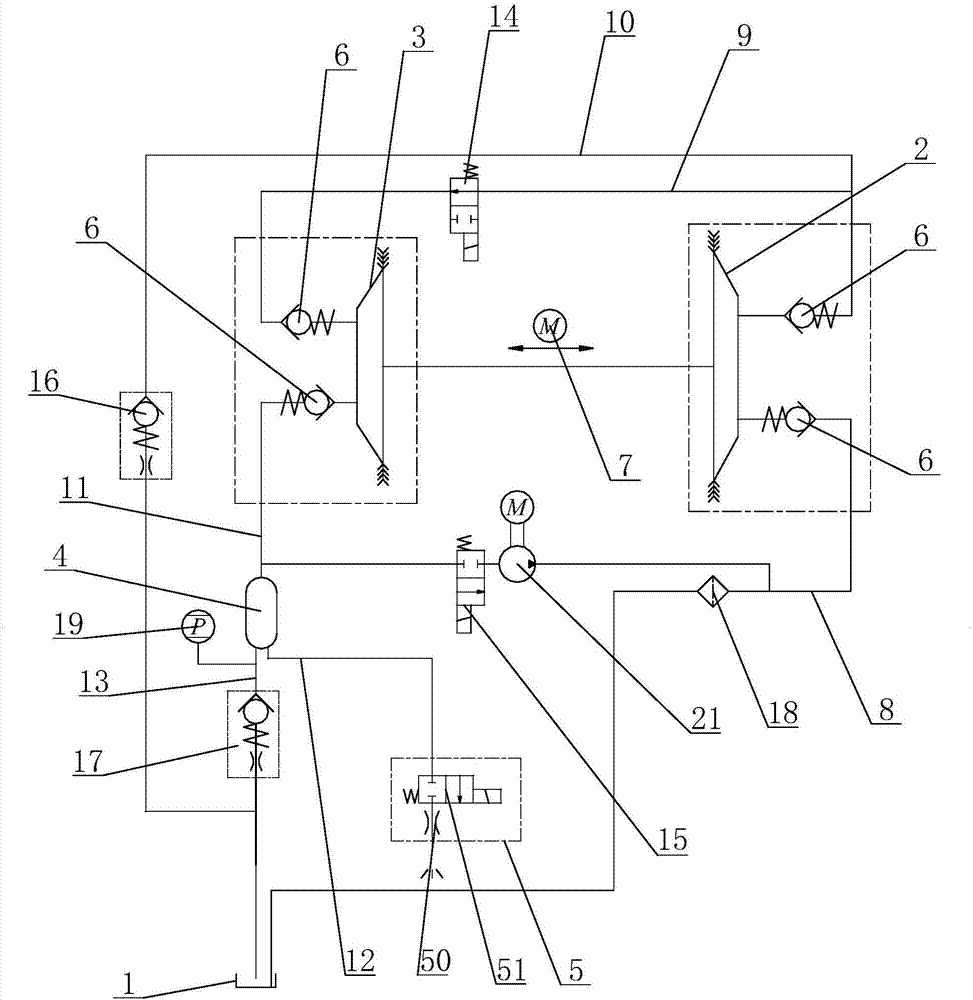

[0032] see figure 2 as shown, figure 2 It is a schematic structural diagram of the urea solution supply system provided in Embodiment 2 of the present invention.

[0033] The main difference between this embodiment and Embodiment 1 is that: a reverse suction pump 21 is installed on the pipeline between the liquid inlet pipeline 8 and the first liquid outlet pipe 11, and the second reversing valve 15 adopts a two-position two-position valve. The electromagnetic valve is connected, and the setting of the third reversing valve 20 is omitted at the same time, and the back pumping process is realized by the back pump 21, and the back pump 21 adopts any one of motor drive or electromagnetic drive. All the other parts are identical to the structure of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com