Catalytic cracking oil slurry pretreatment system and pretreatment method by utilization of system

A technology for catalytic cracking oil slurry and pretreatment, which is applied in the treatment of hydrocarbon oil, multi-stage series-connected refining process treatment, petroleum industry, etc. The effect of high extraction efficiency and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

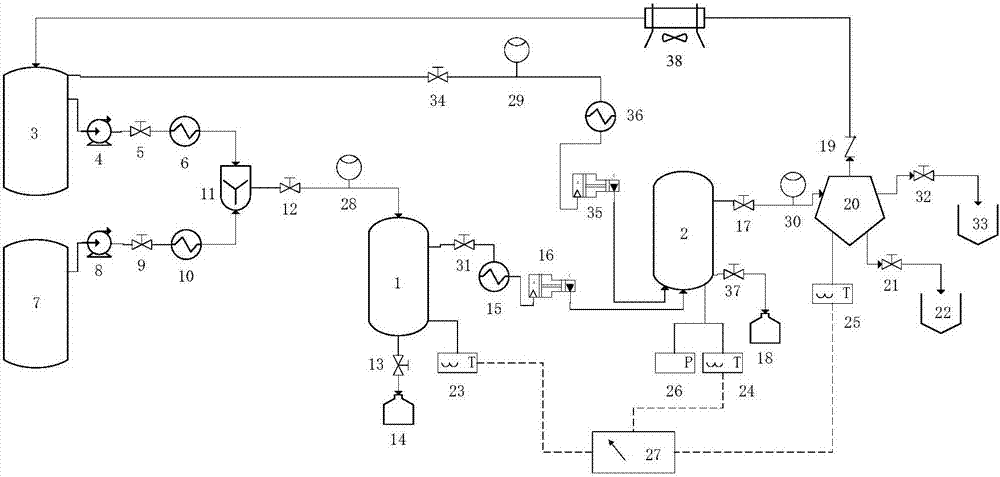

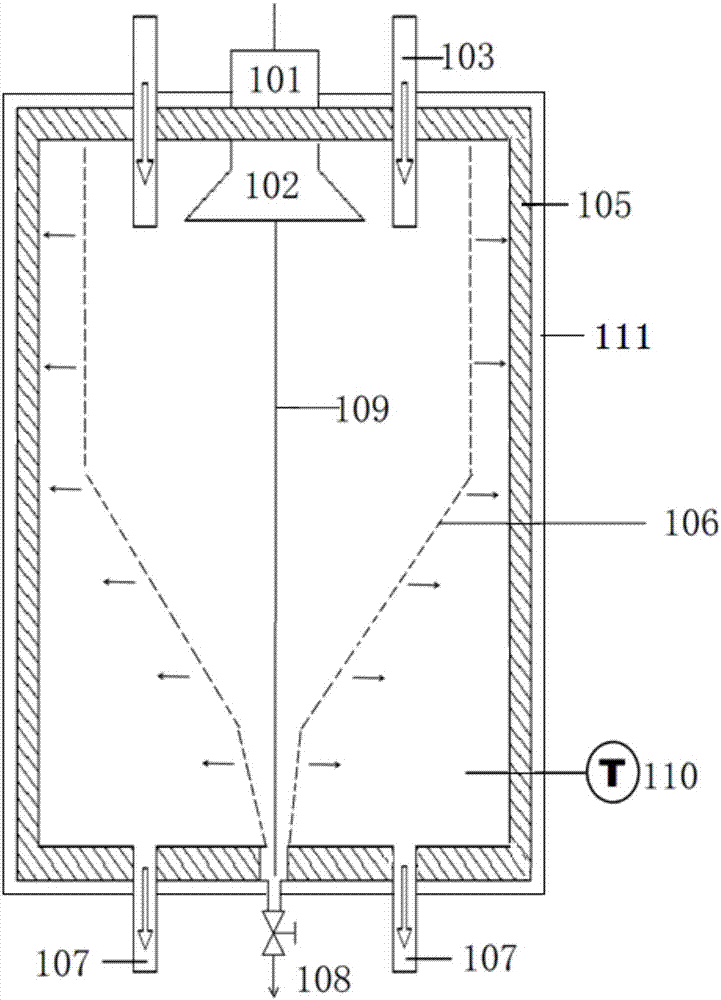

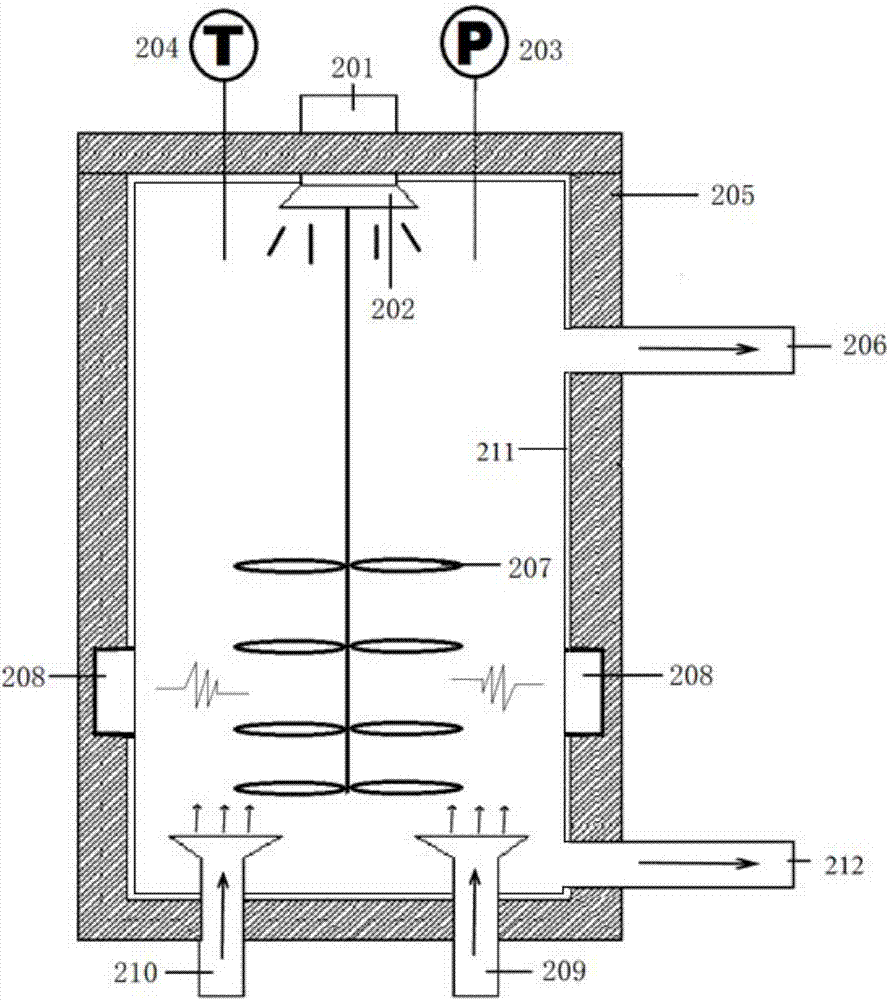

[0037] Specific Embodiment 1: In this embodiment, a catalytic cracking oil slurry pretreatment system includes a solvent tank 3, a catalytic cracking oil slurry tank 7, a mixer 11, an ultrasonic centrifugal separation device 1, an ultrasonic and microwave-enhanced supercritical extraction device 2, a separation Device 20, solid particle collection tank 14, heavy component collector 22 and light component collector 33;

[0038] Wherein, an outlet of the solvent tank 3 communicates with an inlet of the mixer 11, and a first high-pressure pump 4, a first screw valve 5 and a first heating system 6 are arranged between the solvent tank 3 and the mixer according to the flow direction of the medium, and the catalytic The outlet of the cracked oil slurry tank 7 communicates with the other inlet of the mixer 11, and a second high-pressure pump 8, a second screw valve 9 and a second heating device are arranged between the catalytic cracked oil slurry tank 7 and the mixer 11 according to ...

specific Embodiment approach 2

[0042] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrasonic centrifugal separation device 1 is connected to the first thermocouple, the ultrasonic synergistic microwave enhanced supercritical extraction device 2 is connected to the second thermocouple, and the separator 20 is connected to the third thermocouple. I. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the first thermocouple 23 , the second thermocouple 24 and the third thermocouple 25 are all connected to an electronic temperature control system 27 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com