Filter mud containing clean coal and preparation method thereof

A mud filtering and cleaning technology, applied in the field of clean briquette and its preparation, can solve problems such as failing to meet the quality requirements of clean briquette, and achieve the effects of improving sulfur fixation, reducing emissions, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

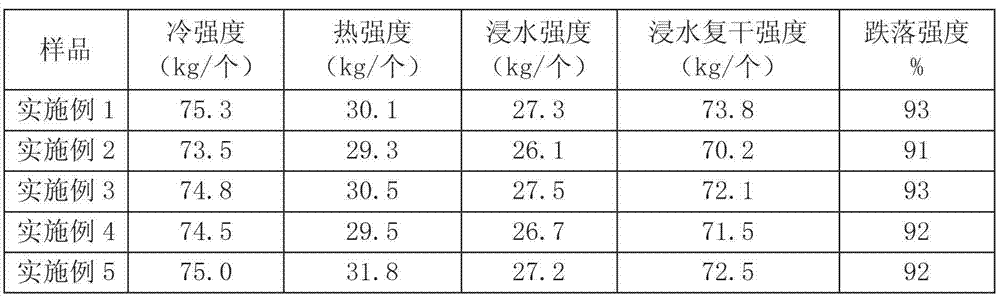

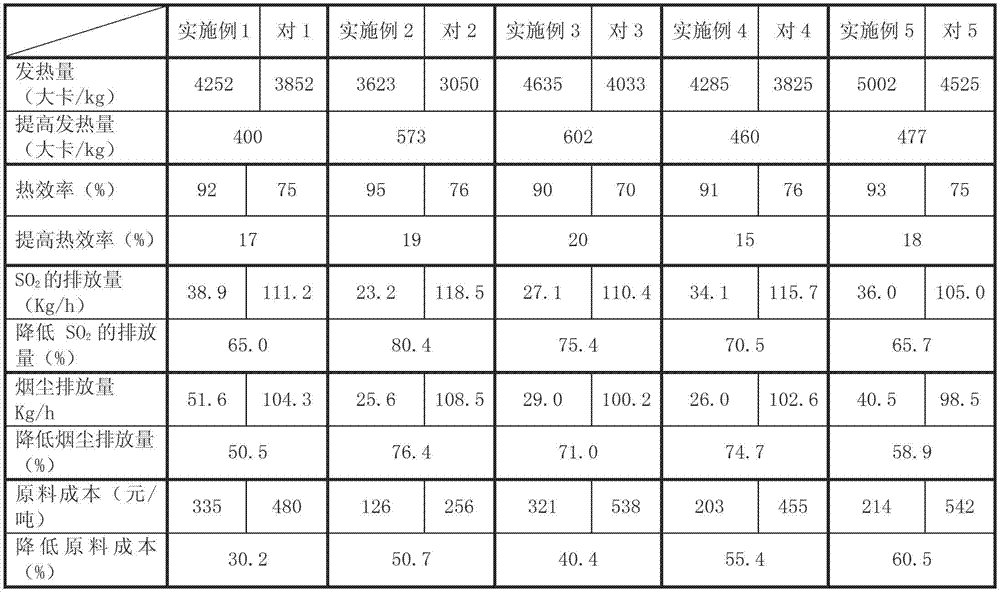

Examples

Embodiment 1

[0033] A method for preparing clean briquettes containing filter mud, comprising the following steps:

[0034] 1. Weigh respectively according to the weight ratio of raw material components: bituminous coal powder 25kg, filter mud 10kg, potassium nitrate 0.002kg, sodium chloride 0.1kg, pregelatinized starch 0.2kg, kaolin 0.5kg, polyvinyl alcohol 0.1kg , calcium hydroxide 0.6kg, sodium carbonate 0.03kg, ascorbic acid 0.003kg, ferrous sulfate 0.1kg;

[0035] 2. Mix pregelatinized starch and kaolin evenly to obtain mixture A;

[0036] 3. Add mixture A to bituminous coal powder and filter mud, stir and mix evenly to obtain mixture B;

[0037] 4. Add water accounting for 6% of the total weight of raw material components into the reactor, add polyvinyl alcohol, heat to 80°C, stir to dissolve completely, and then add potassium nitrate, sodium chloride, calcium hydroxide, sodium carbonate, Ascorbic acid and ferrous sulfate are stirred to make the mixture uniform, and mixed solution ...

Embodiment 2

[0041] A method for preparing clean briquettes containing filter mud, comprising the following steps:

[0042] 1. Weigh respectively according to the weight ratio of raw material components: lignite powder 35kg, filter mud 55kg, potassium nitrate 0.003kg, sodium chloride 0.2kg, pregelatinized starch 0.3kg, kaolin 0.8kg, polyvinyl alcohol 0.2kg, Calcium hydroxide 0.9kg, sodium carbonate 0.06kg, ascorbic acid 0.005kg, ferrous sulfate 0.125kg;

[0043] 2. Mix pregelatinized starch and kaolin evenly to obtain mixture A;

[0044] 3. Add mixture A to lignite powder and filter mud, stir and mix evenly to obtain mixture B;

[0045] 4. Add water accounting for 10% of the total weight of raw material components into the reactor, add polyvinyl alcohol, heat to 85°C, stir to dissolve completely, and then add potassium nitrate, sodium chloride, calcium hydroxide, sodium carbonate, Ascorbic acid and ferrous sulfate are stirred to make the mixture uniform, and mixed solution C is obtained;...

Embodiment 3

[0048] A method for preparing clean briquettes containing filter mud, comprising the following steps:

[0049] 1. Weigh respectively according to the weight ratio of raw material components: 70kg of anthracite powder, 15kg of coal gangue powder, 65kg of filter mud, 0.05kg of potassium nitrate, 0.6kg of sodium chloride, 2.8kg of pregelatinized starch, 3kg of refractory mud, kaolin 3kg, polyvinyl alcohol 0.5kg, calcium hydroxide 1.5kg, sodium carbonate 0.5kg, ascorbic acid 0.02kg, ferrous sulfate 0.3kg;

[0050] 2. Mix pregelatinized starch, refractory clay and kaolin evenly to obtain mixture A;

[0051] 3. Add mixture A to anthracite powder, coal gangue powder and filter mud, stir and mix evenly to obtain mixture B;

[0052] 4. Add water accounting for 10% of the total weight of raw material components into the reactor, add polyvinyl alcohol, heat to 83°C, stir to dissolve completely, and then add potassium nitrate, sodium chloride, calcium hydroxide, sodium carbonate, Ascorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com