Variant-hydrochloric-acid-concentration acid fracturing method for carbonate reservoir

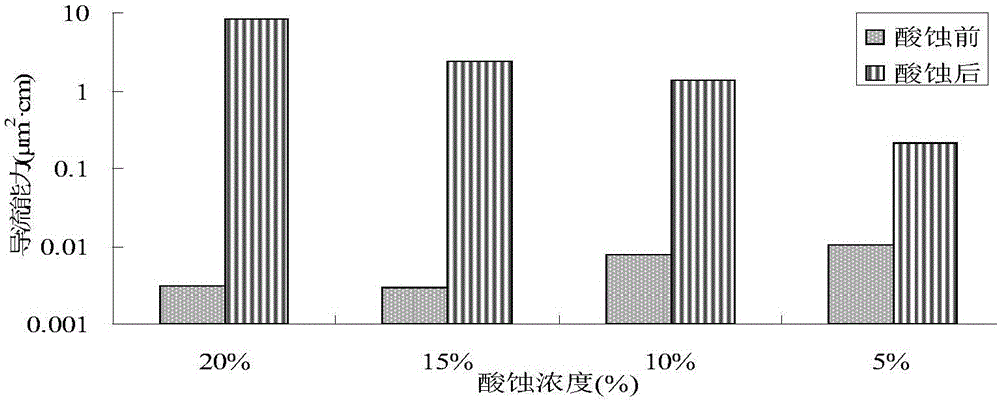

A carbonate rock reservoir, hydrochloric acid concentration technology, applied in chemical instruments and methods, earthwork drilling, production of fluids, etc., can solve the problems of lowering the cloud point of the demulsifier and weakening the demulsifier's demulsification ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

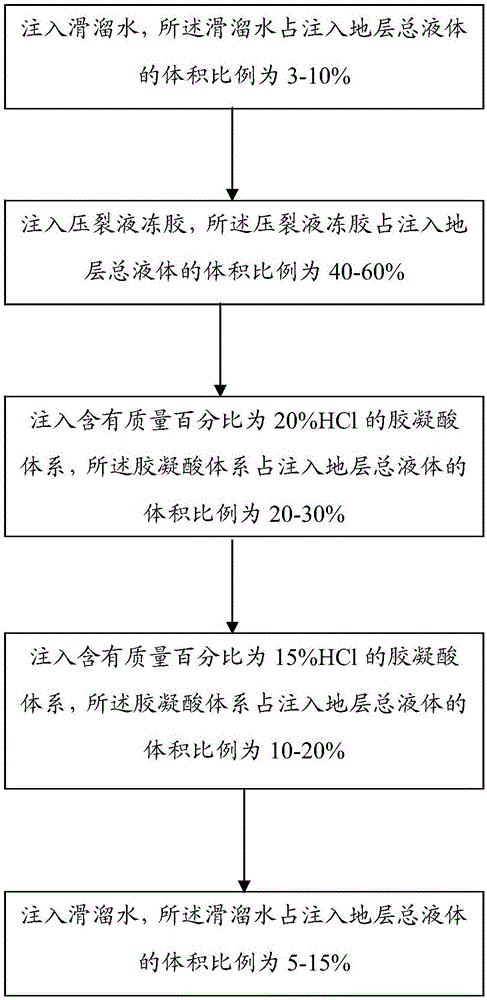

Method used

Image

Examples

Embodiment

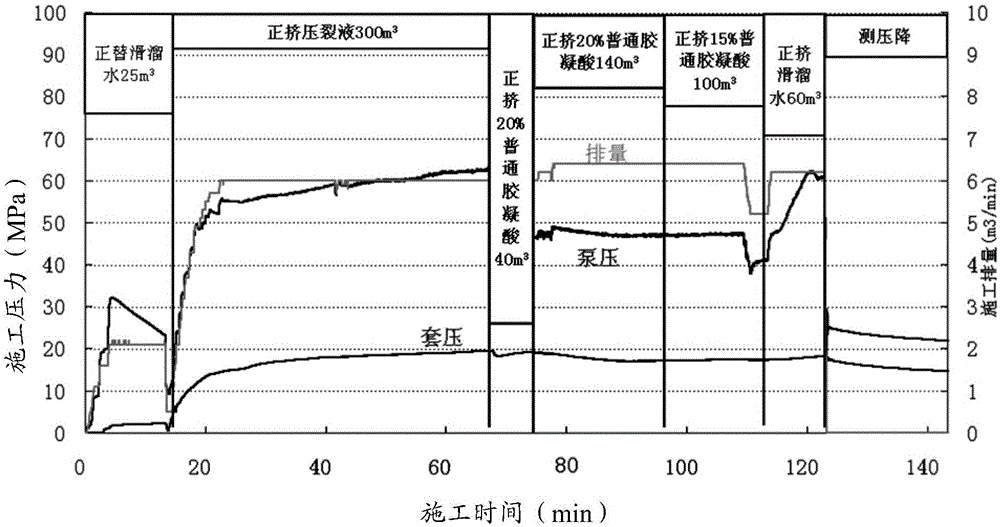

[0074] The acid fracturing method for variable hydrochloric acid concentration of carbonate rock reservoirs of the present invention will be described in detail below through the field test of Tahe Oilfield.

[0075] Firstly, the liquid composition involved in the acid fracturing pump injection process is described as follows, and the following percentages refer to mass % unless otherwise specified.

[0076] Slick water: Guar gum of model GRJ-11 sold by Jianghan Fracturing Company + additives sold by Xinjiang Luntai Like Oilfield Technical Service Co., Ltd., the composition is: 0.2% GRJ-11 guar gum + 0.1% GX-3 fungicide + 0.025% pH regulator, and the rest is water, wherein the guar gum is usually guar gum hydroxypropyl trimethyl ammonium chloride.

[0077] Fracturing fluid: the above-mentioned guar gum + additives sold by Xinjiang Luntai County Like Oilfield Technical Service Co., Ltd., the composition is: 0.5% GRJ-11 guar gum + 0.02% pH regulator + 1.0% HS-308 cracking fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com