Solid type crude oil demulsifier and preparation method and application thereof

A crude oil demulsifier and body type technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of difficult demulsification of heavy oil, lower demulsification efficiency, general penetration and diffusion performance, etc., and achieve significant demulsification and dehydration performance, The effect of improving demulsification efficiency and demulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 provides a method for preparing a bulk crude oil demulsifier, including the following steps:

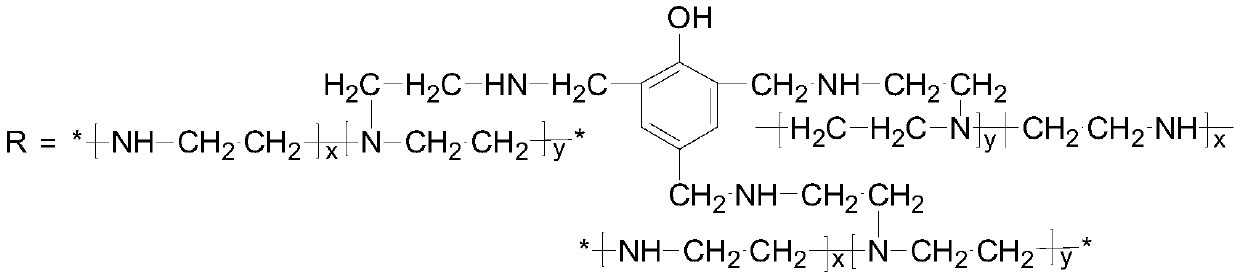

[0059] (1) Preparation of initiator R

[0060] Add 300kg of xylene, 700kg of polyvinyl polyamine, and 90kg of molten phenol to a dry and clean electric heating reactor. The temperature is increased to 50℃~60℃, and the mixture is stirred until the state is uniform; Add 240kg of formaldehyde solution with 37% content and control the dripping time for 0.5h~1h. After the dripping is completed, keep the reaction for 2h; then increase the temperature to 120℃~130℃ and continue the constant temperature reaction for 2h, continue to increase the temperature to 150℃~160℃, Reflux dehydration for 6 hours until no water is removed, continue to heat up to 220 ℃ ~ 240 ℃, dehydration and solvent removal for 4 hours until no liquid is removed, and cool down to 100 ℃ ~ 110 ℃ to obtain body resin initiator R, which is transferred to the kettle for later use.

[0061] (2) Preparation of interm...

Embodiment 2

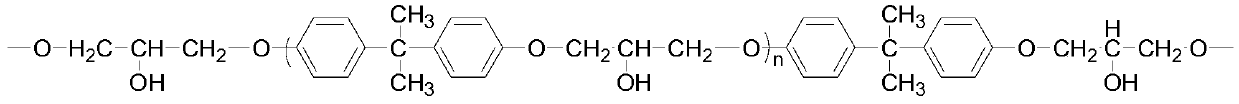

[0066] Example 2 provides a bulk crude oil demulsifier prepared in Example 1. The bulk crude oil demulsifier is a polymer having the following structural formula:

[0067]

[0068] In the formula, the structural formula of Y is as follows:

[0069]

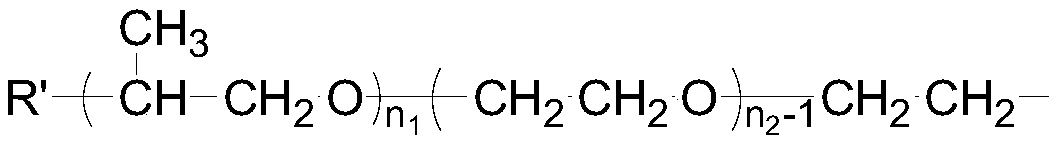

[0070] In the formula, R'is the R in the following formula to remove active hydrogen:

[0071]

[0072] Where: n 1 Take 1~30, n 2 Take 1 to 5; among them, the active hydrogen on R includes the hydrogen on the phenyl hydroxyl group and the amino hydrogen on the polyvinyl polyamine structure.

[0073] The molecular weight of the obtained polymer is 8000~10000, and the density is 1.00-1.02g / cm 3 , PH value is 7-9, flash point ≥50℃; its appearance is dark yellow viscous uniform liquid, no mechanical impurities, solid content ≥95%; viscosity<300mPa.s, freezing point ≤-35℃, absolute dehydration rate ≥93%.

[0074] In the polymer represented by the above formula, the structure with subscripts x and y is derived from the raw material polyethylene ...

Embodiment 3

[0075] Example 3 Crude oil demulsification experiment

[0076] The above-mentioned crude oil demulsifier is denoted by the code name DST, and the demulsification performance test is carried out. Six kinds of agents with good indoor evaluation effects and on-site agents are selected, and the experiments are carried out under the same temperature and different dosage conditions. Among them, the crude oil sample comes from the Le'an Joint Station, the water content of the oil sample is 30%, the dehydration temperature is 75°C, and the test results obtained are Table 1:

[0077] Table 1 Comparison of the demulsification effect of the bulk crude oil demulsifier provided by the present invention and other demulsifiers at different dosages

[0078]

[0079] Note: The agent used on site is LALP.

[0080] It can be seen from Table 1 that the bulk crude oil demulsifier provided by the present invention has a fast dehydration speed, an oil-water interface is uniform, and the extracted water is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com