Demulsification method of oil-in-water type crude oil emulsion

An oil-in-water, emulsion technology, applied in the direction of dehydration/demulsification by mechanical methods, can solve the problems of continuous production being difficult to proceed smoothly, easily destroying the electric field, failure, etc., and achieve better demulsification effect and demulsification time. Short, stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

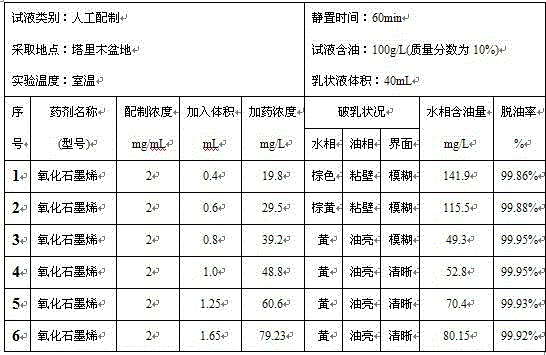

[0024] Prepare a graphite oxide suspension with a concentration of 2 mg / mL with deionized water, and ultrasonically disperse for more than 90 minutes to obtain a graphene oxide dispersion, which is ready for use.

[0025] 40g of Tarim Basin crude oil and 360g of deionized water were respectively placed in plastic containers. The oil-water mixture was dispersed by a high-shear emulsifier at 28,000 rpm for 3 minutes to obtain a uniformly dispersed oil-in-water crude oil emulsion with an oil content of 10%. Take several demulsification reagent bottles and number them sequentially. Add an equal amount of emulsion to the demulsification reagent bottle, and let it stand for 30 minutes at room temperature.

[0026] Add different volumes of graphene oxide dispersion into the demulsification reagent bottle, shake evenly, let stand, observe and record the water phase, oil phase and interface conditions.

[0027] After standing for 60 minutes, refer to the standard analysis method desc...

Embodiment 2

[0032] Prepare a graphite oxide suspension with a concentration of 2 mg / mL with deionized water, and ultrasonically disperse for more than 90 minutes to obtain a graphene oxide dispersion, which is ready for use.

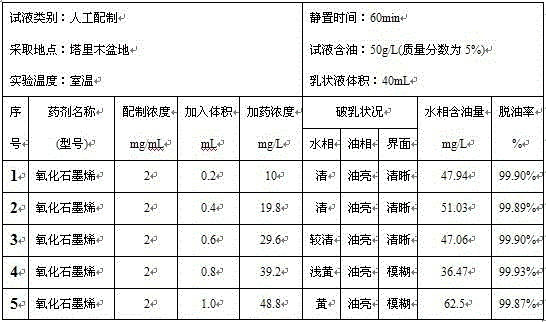

[0033] 20g of Tarim Basin crude oil and 380g of deionized water were placed in plastic containers. The oil-water mixture was dispersed by a high-shear emulsifier at 28,000 rpm for 3 minutes to obtain a uniformly dispersed oil-in-water crude oil emulsion with an oil content of 5%. Take several demulsification reagent bottles and number them sequentially. Add an equal amount of emulsion to the demulsification reagent bottle, and let it stand for 30 minutes at room temperature.

[0034] Add different volumes of graphene oxide dispersions into the demulsification reagent bottle and shake evenly. Stand still, observe and record the condition of water phase, oil phase and interface.

[0035] After standing for 60 minutes, refer to the standard analysis method described...

Embodiment 3

[0040] Prepare a graphite oxide suspension with a concentration of 2 mg / mL with deionized water, and ultrasonically disperse for more than 90 minutes to obtain a graphene oxide dispersion, which is ready for use.

[0041] 2g of Tarim Basin crude oil and 398g of deionized water were placed in plastic containers. The oil-water mixture was dispersed by a high-shear emulsifier at 28,000 rpm for 3 minutes to obtain a uniformly dispersed oil-in-water crude oil emulsion with an oil content of 0.5%. Take several demulsification reagent bottles and number them sequentially. Add an equal amount of emulsion to the demulsification reagent bottle, and let it stand for 30 minutes at room temperature.

[0042] Add different volumes of graphene oxide dispersions into the demulsification reagent bottle and shake evenly. Stand still, observe and record the condition of water phase, oil phase and interface.

[0043] After standing for 60 minutes, refer to the standard analysis method describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com