Boron carbide smelting device and boron carbide preparation method

A smelting device and boron carbide technology, applied in the field of ceramic materials, can solve problems such as unsuitable for large-scale promotion and development, difficult to remove, etc., achieve mass production, reduce energy consumption and material waste, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Specifically, the method for preparing boron carbide based on the above-mentioned boron carbide smelting device comprises the following steps:

[0049] In step S1, the boron source and carbon source are fully mixed to obtain smelting raw materials.

[0050] Specifically, the boron source is boric acid and / or boric anhydride, and the carbon source is at least one of petroleum coke, graphite, amorphous carbon, carbon black, and activated carbon; considering that there will be a slight loss of the boron source, it is therefore preferred to control the smelting The material ratio of boron atoms to carbon atoms in the raw material is 5:1-7:1.

[0051] In step S2, the smelting raw material is completely filled into the smelting furnace body, and the sunken cover plate is covered on the smelting raw material.

[0052] In step S3, voltage is applied to the positive electrode and the negative electrode to heat and smelt the above-mentioned smelting raw materials to obtain boron...

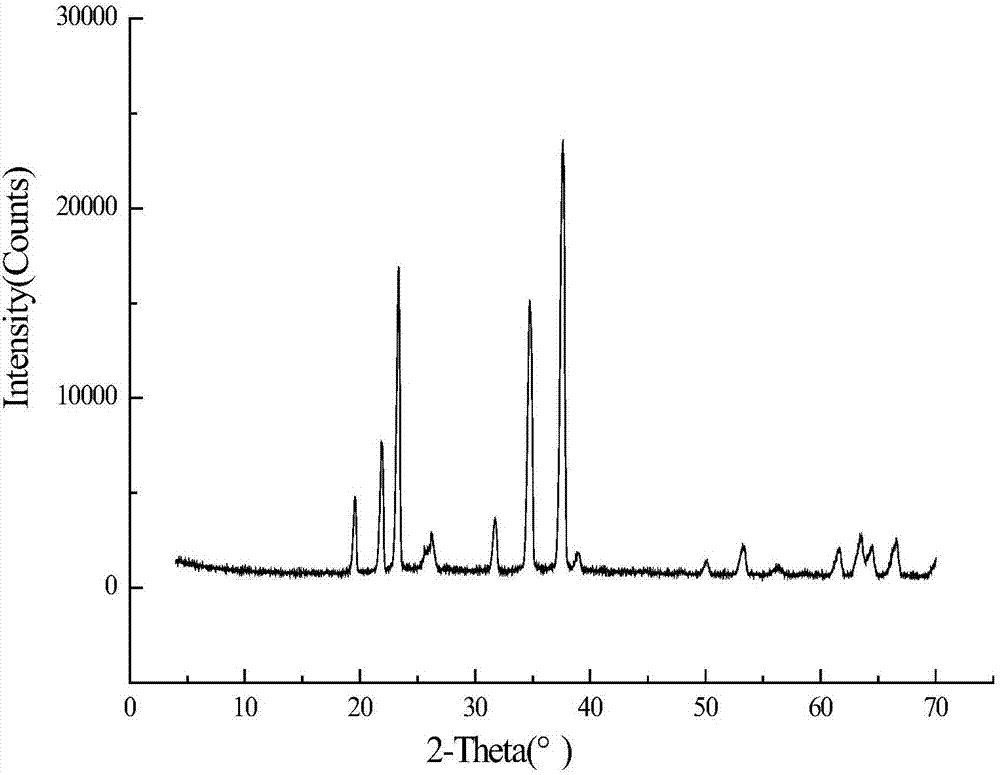

Embodiment 1

[0060] The raw materials are domestic boric acid, petroleum coke and graphite, among which the main content of boric acid is 98.52%, the average particle size is 119μm, and the specific surface area is 1.35m 2 / g. Fully mix 1000kg boric acid, 300kg petroleum coke and 25kg graphite through a mixer to obtain smelting raw materials.

[0061] The smelting raw materials are placed in the boron carbide smelting device for sintering. The specific process of sintering is: 1000KVA transformer (rectifier), 15 levels of on-load tap changers, and the furnace is opened in series to transmit power. According to the furnace resistance and current conditions, it is adjusted to parallel connection. , after changing the parallel mode, gradually increase the gear from the 1st gear, observe the rise of the primary current, and adjust the interval time of the upshift as appropriate, stop the upshift when the primary current reaches about 55A, and drop 1 gear every time the primary current reaches ...

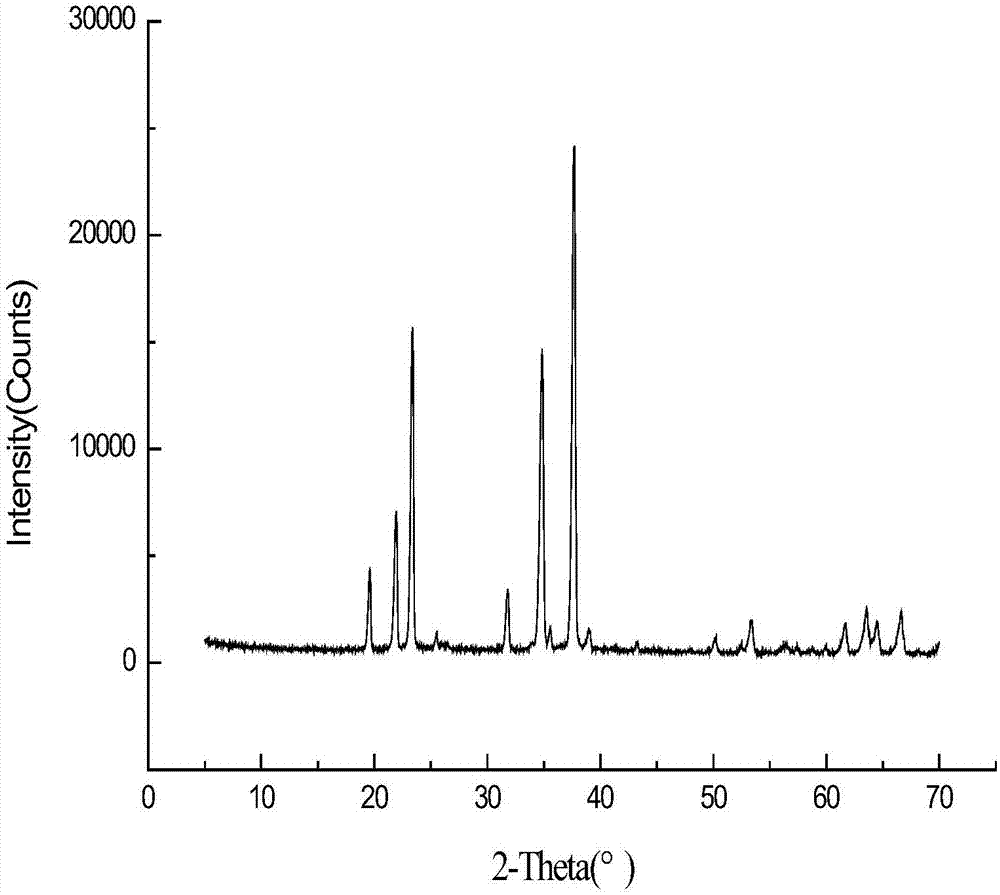

Embodiment 2

[0067] The raw materials are domestic boric acid, boric anhydride, petroleum coke, carbon black and graphite, among which the main content of boric acid is 98.52%, the average particle size is 119μm, and the specific surface area is 1.35m 2 / g. Stir and mix 800kg boric acid, 400kg boric anhydride, 275kg petroleum coke, 10kg conductive carbon black and 25kg graphite, then press it into cylindrical particles with a length of 1.2cm to 3cm through a particle molding machine, and the compacted density is about 1.22g / cm 3 , to obtain smelting raw materials.

[0068] The smelting raw materials are placed in the boron carbide smelting device for sintering. The specific process of sintering is: 1000KVA transformer (rectifier), 15 levels of on-load tap changers, and the furnace is opened in series to transmit power. According to the furnace resistance and current conditions, it is adjusted to parallel connection. , after changing the parallel mode, gradually increase the gear from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com