Novel technique for synthesizing solvent yellow 163

A synthesis process and solvent technology, applied in the field of solvent yellow 163 synthesis process, can solve the problems of complex preparation process, high production cost, large fluctuation of product appearance and content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

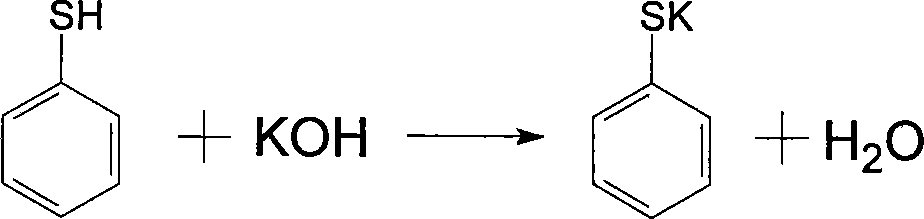

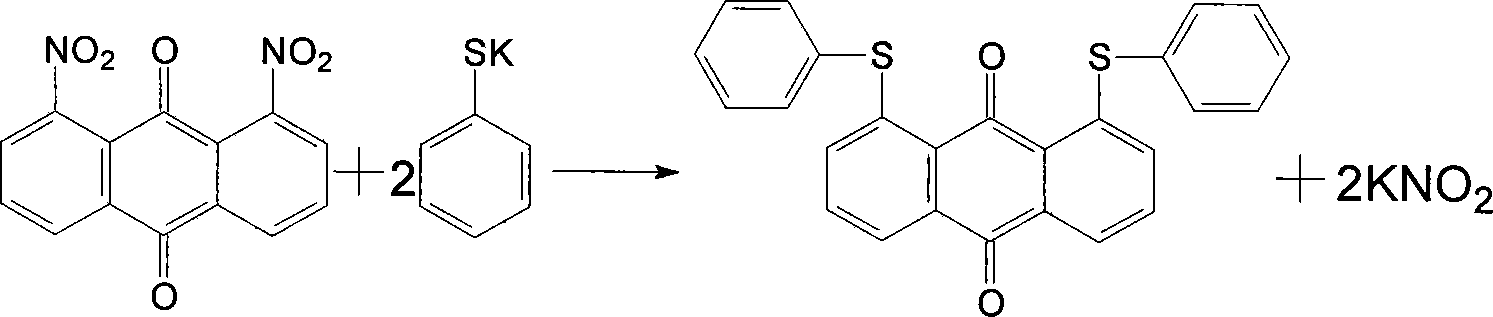

Method used

Image

Examples

Embodiment 1

[0015] In a 250ml four-neck flask, add 100ml of dimethylformamide, 30g of 1,8-dinitroanthraquinone, 24g of thiophenol, and 12g of potassium hydroxide. After the addition, slowly raise the temperature to 50°C for about one hour and keep it warm. React for two hours, after the chromatographic detection of 1,8-dinitroanthraquinone disappears, use a cold water bath to cool down to 25°C, keep stirring at this temperature for one hour, then filter, and wash the filter cake with dimethylformamide containing 20% water Then wash it with hot water at about 80° C., and dry the filter cake to obtain 41 g of finished product, with a content of 99.5% and a yield of 96%.

Embodiment 2

[0017] In a 250ml four-neck flask, add 120ml of dimethylformamide, 30g of 1,8-dinitroanthraquinone, 24g of thiophenol, and 12g of potassium hydroxide. After the addition, slowly raise the temperature to 50°C for about one hour to keep the temperature React for two hours, after the chromatographic detection of 1,8-dinitroanthraquinone disappears, use a cold water bath to cool down to 25°C, keep stirring at this temperature for one hour, then filter, and wash the filter cake with dimethylformamide containing 20% water Then wash it with hot water at about 80° C., and dry the filter cake to obtain 40 g of finished product, with a content of 99.8% and a yield of 93.7%.

Embodiment 3

[0019] In a 250ml four-neck flask, add 100ml of dimethylacetamide, 30g of 1,8-dinitroanthraquinone, 24g of thiophenol, and 12g of potassium hydroxide. After 1,8-dinitroanthraquinone disappears, use a cold water bath to cool down to 25°C, keep stirring at this temperature for one hour and then filter. The filter cake is washed with dimethylacetamide containing 20% water and then washed with 80°C or so After washing with hot water, the filter cake was dried to obtain 41.5 g of finished product with a content of 99.4% and a yield of 97.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com