Equipment and process for recovering glyphosate solvent during production with glycine method

A recovery equipment and glyphosate technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of high labor intensity, discontinuous operation, high energy consumption, etc., and achieve the degree of automation High efficiency, wide application prospects and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

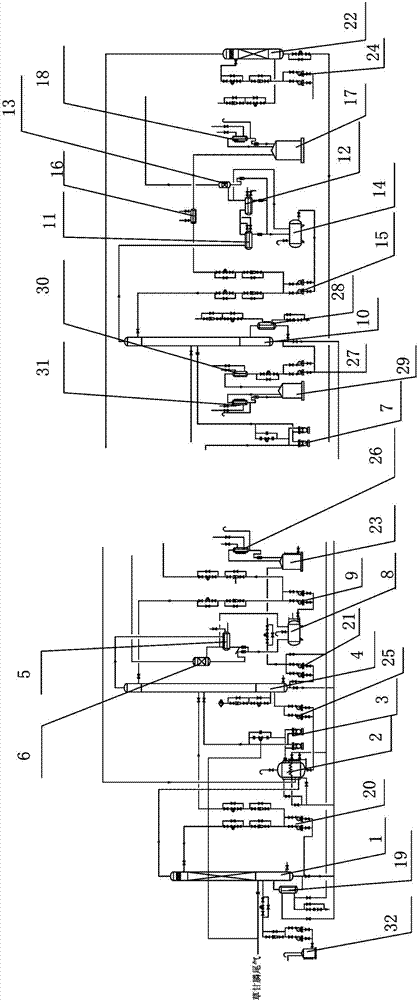

[0025] Glyphosate produced by the glycine method will produce a large amount of mixed gases such as methyl chloride, methanol, methylal, and water vapor in the process of desolventization and deacidification. The traditional process is to condense the mixed gas through three stages, methanol, methylal, water (dilute methanol) are condensed and enter the storage tank, and the uncondensed methyl chloride (entrained methanol, methylal) enters the methyl chloride recovery device. Dilute methanol is neutralized with liquid caustic soda, and the neutralized liquid is injected into the rectification system to recover methanol formal. The traditional process has high energy consumption, high consumption in the recovery process of methyl chloride, and low content of methyl chloride. Through technical research, a gas phase recovery process was invented. The process is to directly enter the mixed gas in the process of desolventization and deacidification into the neutralization tower, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com