Method of producing neutral high quality anhydrous sodium sulfate using natucal salt lake sodium sulfate decahydrate

A technology of sodium sodium sulfate and sodium sulfate, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal sulfite/sulfate purification, etc., can solve the problems of sodium sulfate purity, whiteness, Alkali content is not ideal enough to achieve the effect of increasing technological added value, easy control, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

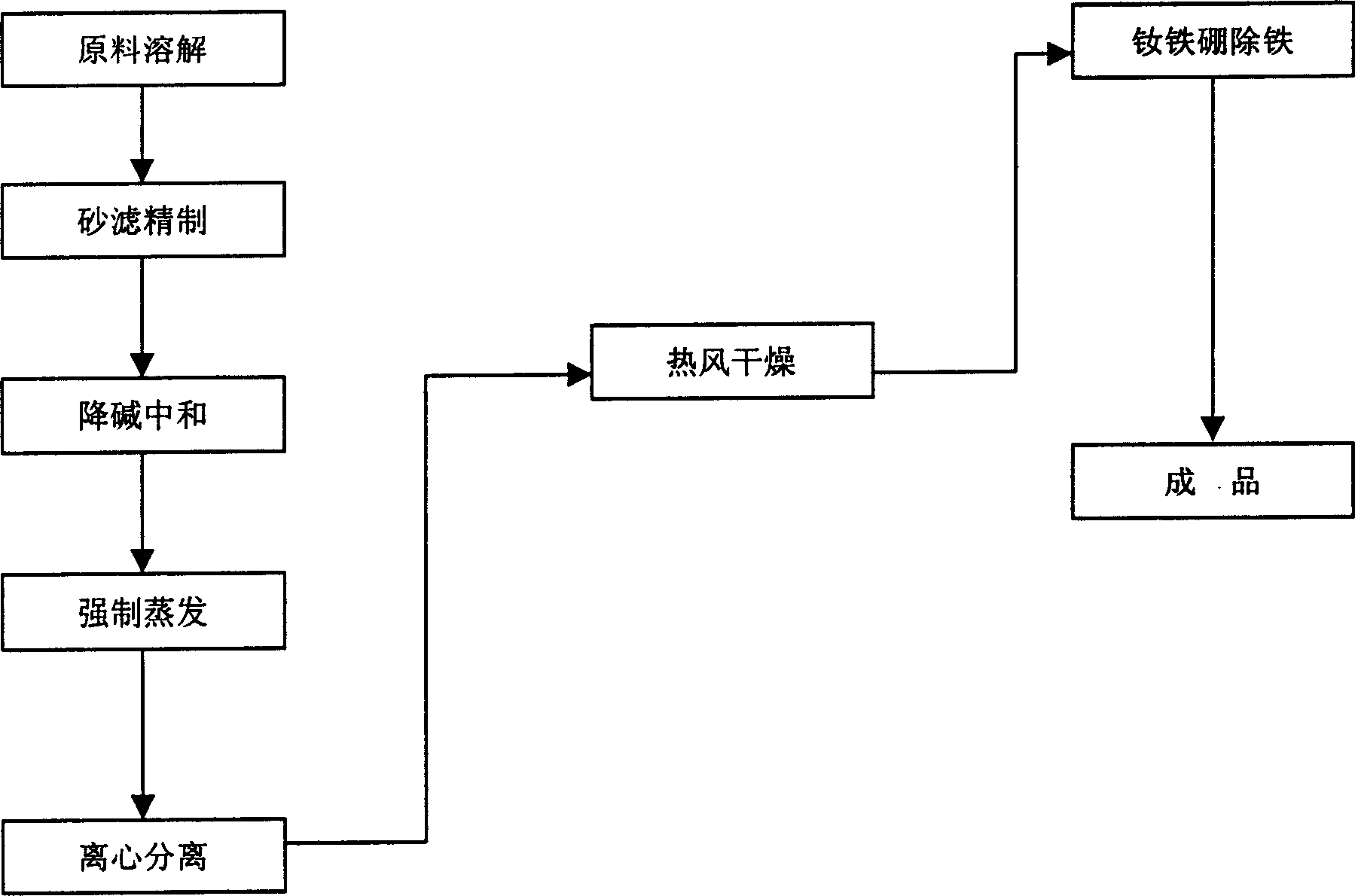

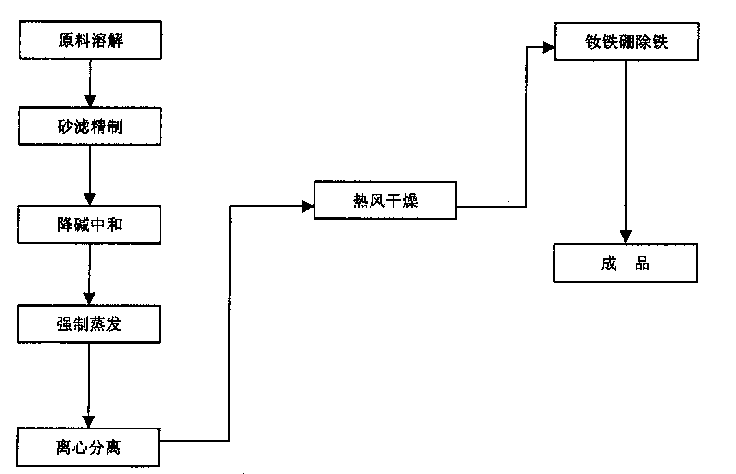

[0007] Embodiment: (see figure)

[0008] Glauber's salt resources in salt lakes (resources are saline-alkali nitrate symbiotic mines), crystalline nitrate produced through cold and hot brine making process and nitrate sun drying process as raw materials, in which the content of sodium sulfate is more than 40%, and the content of sodium chloride is 8-12% %, the sodium carbonate content is 5-10%; dissolving sodium Glauber's salt in water, so that the concentration of the clear solution is 250-350 grams per liter; let the clear solution pass through the sand bed to filter and refine, so that the turbidity of the filtered clear solution is less than 10ppm, wherein the thickness of the sand bed is 0.6-0.7 meters, and the diameter of the sand grains is 0.45-0.6 millimeters; add ammonium sulfate to reduce alkali and neutralize in the filtered nitric acid solution: , the add-on of ammonium sulfate is 80-90% that contains sodium carbonate total amount in the clear nitric liquid; E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com