Method of producing dichromium trioxide using chromic acid thermal decomposition continuous method

A technology of chromium trioxide and thermal decomposition, applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of inability to realize continuous production, insufficient collection and treatment, high labor intensity of employees, etc., to achieve pure color, The effect of lowering cost and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

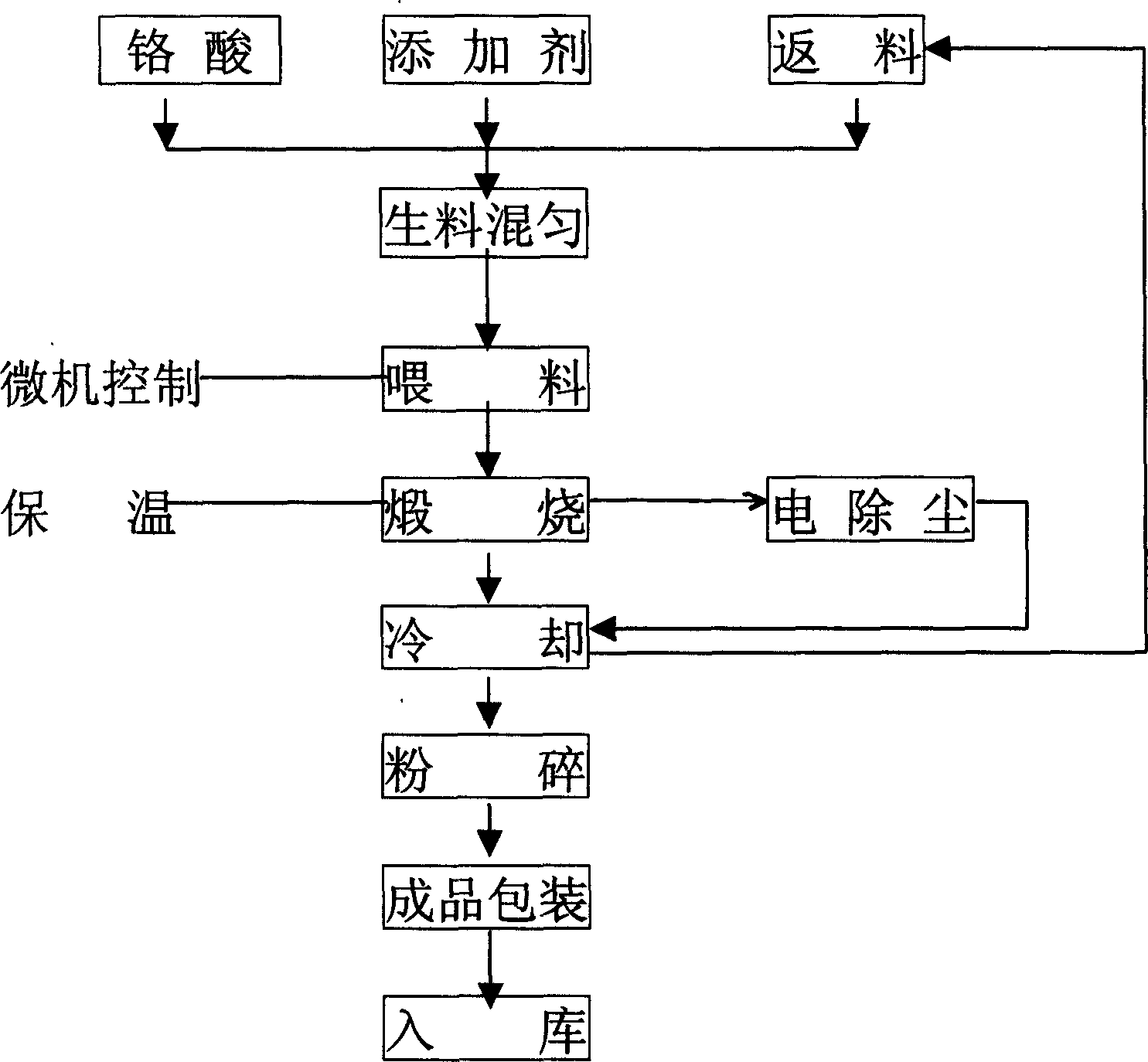

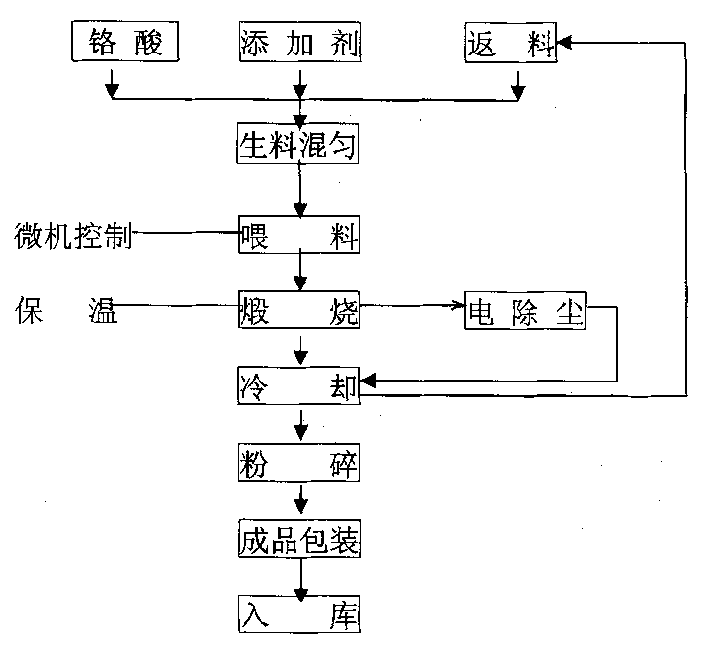

Image

Examples

example 1

[0029] With chromic acid (containing Cr 2 o 3 ≥99.5) and thick dichromium trioxide, boric acid, under the control of microcomputer, mix uniformly, its material ratio is chromic acid: thick dichromium trioxide: boric acid=100: 3: 0.2 (weight); Quantitative input rotary kiln fuel At the injection end, liquefied gas is used as the roasting fuel, which is directly in contact with the material and burned in parallel. During the slow and uniform rotation of the rotary kiln, the material quickly enters the high-temperature zone for roasting. The temperature in the high-temperature zone is 1000°C; the reaction time is 40 minutes; After the violent thermal decomposition reaction, the chromic acid is converted into dichromium trioxide; the dichromium trioxide is kept warm in the rotary kiln for 80 minutes; then it comes out of the tail of the rotary kiln, and the temperature of the kiln tail is 420°C. After cooling and crushing, it becomes a qualified chromium trioxide product; after c...

example 2

[0031] With chromic acid (containing Cr 2 o 3 ≥99.5) and thick dichromium trioxide, boric acid, under the control of microcomputer, mix evenly, its material ratio is chromic acid: thick dichromium trioxide: boric acid=100: 4: 0.3 (weight); Quantitative input rotary kiln fuel At the injection end, liquefied gas is used as the roasting fuel, which is directly in contact with the material and burned in parallel. During the slow and uniform rotation of the rotary kiln, the material quickly enters the high-temperature zone for roasting. The temperature in the high-temperature zone is 1050°C; the reaction time is 45 minutes; After the violent thermal decomposition reaction, the chromic acid is transformed into dichromium trioxide; the dichromium trioxide is kept warm in the rotary kiln for 90 minutes; then it comes out of the tail of the rotary kiln, and the temperature of the kiln tail is 435°C. After cooling and crushing, it becomes a qualified chromium trioxide product; after co...

example 3

[0033] With chromic acid (containing Cr 2 o 3 ≥99.5) and thick dichromium trioxide, boric acid, under the control of microcomputer, mix evenly, its material ratio is chromic acid: thick dichromium trioxide: boric acid=100: 5: 0.4 (weight); Quantitative input rotary kiln fuel At the injection end, liquefied gas is used as the roasting fuel, which is directly in contact with the material and burned in parallel. During the slow and uniform rotation of the rotary kiln, the material quickly enters the high-temperature zone for roasting. The temperature in the high-temperature zone is 1100°C; the reaction time is 52 minutes; After the violent thermal decomposition reaction, the chromic acid is transformed into dichromium trioxide; the dichromium trioxide is kept warm in the rotary kiln for 105 minutes; then it comes out from the tail of the rotary kiln with a temperature of 442°C. After cooling and crushing, it becomes a qualified chromium trioxide product; after cooling, the ungro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com