High-purity zirconium oxychloride extraction process

A technology of high-purity zirconium oxychloride and pure zirconium oxychloride, which is applied in the field of high-purity zirconium oxychloride extraction technology, can solve the problems of "three wastes", discontinuous alkali fusion sintering process, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, further illustrate the present invention.

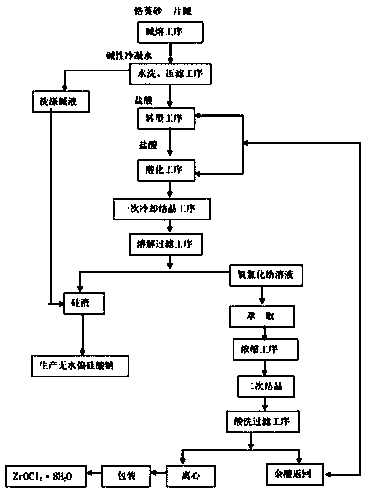

[0027] see figure 1 As can be seen, a kind of high-purity zirconium oxychloride extraction process of the present invention comprises the following steps:

[0028] (1) Alkali fusion process is to add zircon sand to caustic soda at 600°C and melt it for 15 minutes to obtain zirconium silicate and sodium silicate:

[0029] (2) Water washing and pressure filtration process, wash off the sodium silicate after water washing, form sodium silicate aqueous solution as a by-product for sale, zirconium silicate becomes filter cake after water washing and pressure filtration;

[0030] (3) Transformation process, after adding water to the filter cake in step (2) and stirring it into a slurry, adding mother liquor water to adjust the pH value to 6.5---7.5, and then press-filtering to form a filter cake;

[0031] (4) Acidification process. The filter cake in step (3) is mixed with eluent to form a slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com