Long-time iodine flow supply device

A supply device and long-term technology, which is applied to laser parts, electrical components, lasers, etc., can solve the problems of iodine vapor flow rate drop, slow conduction efficiency, and iodine vapor drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

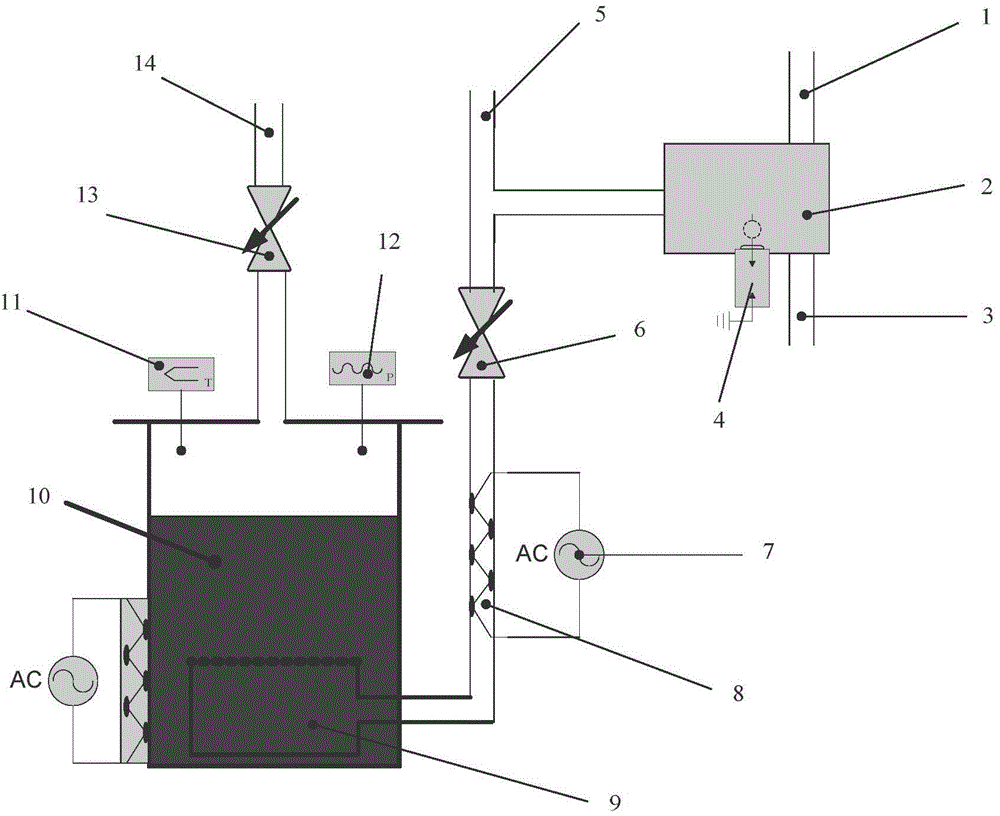

[0010] Such as figure 1 As shown, the cavity 2 and the tank body 10 are respectively the combustion chamber and the fluid storage tank for the material iodine. The combustion chamber is made of stainless steel and cannot leak air at high pressure. The periphery of the combustion chamber is the intake lines 2 and 3 for oxygen and carbon monoxide. A spark plug 4 for ignition is connected to the outer wall of the combustion chamber. Pipeline 5 is used to add diluent gas such as helium or nitrogen to adjust the gas temperature. After the high-temperature carbon dioxide gas flows out from the combustion chamber, it mixes with the low-temperature helium gas, flows through the pneumatic valve 6 and enters the gas distributor 9 . The connecting pipeline between the pneumatic valve and the gas distributor is heated by a temperature-controlled power supply 7 and a heating belt 8, so that its temperature is the same as or slightly higher than the stable temperature in the tank. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com