Preparation method of CuI nanostructure

A technology of nanostructure and electron beam evaporation, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of low preparation temperature, complicated operation, high preparation temperature, etc., and achieve simple preparation method and large area Uniformity and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a CuI nanostructure, comprising the steps of:

[0026] 1) The monocrystalline silicon (100) substrate is cleaned by standard RCA to remove organic matter, metal ion impurities and dust on the surface, blown dry with nitrogen gas, and put it into the vacuum growth chamber of the electron beam evaporation device;

[0027] 2) Electron beam evaporation method grows a layer of copper thin film on the surface of single crystal silicon (100) substrate, and its specific process condition is that the background vacuum is 5×10 -4 ~3×10 -3 pa, the substrate temperature is 25-30°C, the growth rate is 0.15nm / s, the purity of the copper evaporation source used is 99.999wt%, and the thickness of the obtained copper film is 200nm;

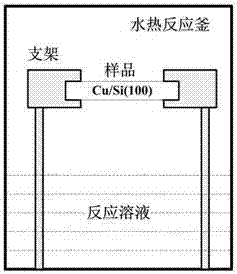

[0028] 3) with step 2) gained silicon-based copper thin film such as figure 1 The suspension shown in the reactor, CuCl in the precursor solution of the reactor 2 The concentration of polyvinylpyrrolidone is 0.1mol / L, the concentra...

Embodiment 2

[0032] A method for preparing a CuI nanostructure, comprising the steps of:

[0033] 1) The monocrystalline silicon (100) substrate is cleaned by standard RCA to remove organic matter, metal ion impurities and dust on the surface, blown dry with nitrogen gas, and put it into the vacuum growth chamber of the electron beam evaporation device;

[0034] 2) Electron beam evaporation method grows a layer of copper thin film on the surface of single crystal silicon (100) substrate, and its specific process condition is that the background vacuum is 5×10 -4 ~3×10 -3 pa, the substrate temperature is 25-30°C, the growth rate is 0.15nm / s, the purity of the copper evaporation source used is 99.999wt%, and the thickness of the obtained copper film is 50nm;

[0035] 3) with step 2) gained silicon-based copper thin film such as figure 1 The suspension shown in the reactor, CuCl in the precursor solution of the reactor 2 The concentration of polyvinylpyrrolidone is 0.05mol / L, the concentra...

Embodiment 3

[0039] A method for preparing a CuI nanostructure, comprising the steps of:

[0040] 1) The monocrystalline silicon (100) substrate is cleaned by standard RCA to remove organic matter, metal ion impurities and dust on the surface, blown dry with nitrogen gas, and put it into the vacuum growth chamber of the electron beam evaporation device;

[0041] 2) Electron beam evaporation method grows a layer of copper thin film on the surface of single crystal silicon (100) substrate, and its specific process condition is that the background vacuum is 5×10 -4 ~3×10 -3 pa, the substrate temperature is 25-30°C, the growth rate is 0.15nm / s, the purity of the copper evaporation source used is 99.999wt%, and the thickness of the obtained copper film is 50nm;

[0042] 3) with step 2) gained silicon-based copper thin film such as figure 1 The suspension shown in the reactor, CuCl in the precursor solution of the reactor 2 The concentration of polyvinylpyrrolidone is 2mol / L, the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com