Method for producing organic electroluminescence device

An electroluminescent device and device technology, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effects of compatible preparation processes, easy operation, and increased injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

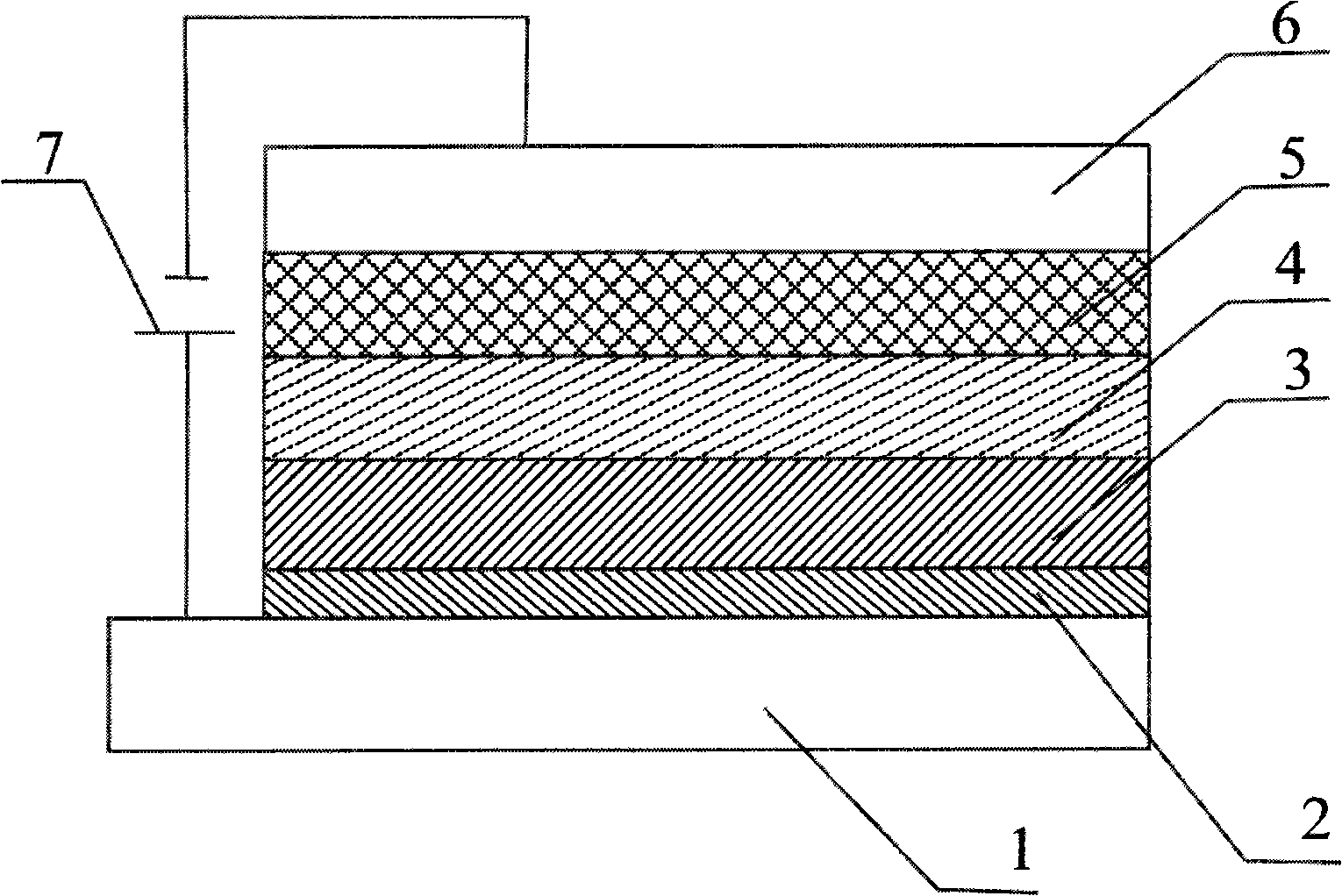

[0062] Such as figure 1 As shown, the organic functional layers in the device structure include a hole transport layer 3, a light emitting layer 4 and an electron transport layer 5, wherein the light emitting layer 4 is a blue light emitting layer or a green light emitting layer respectively.

[0063] The material of the hole transport layer of the device is NPB, and the material of the light emitting layer is BAlq or Alq 3 , the electron transport material is Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0064] Glass substrate / ITO / {3,4-polyethylenedioxythiophene / polystyrenesulfonic acid / 3,4-polyethylenedioxythiophene nanoparticles (particle size 20nm) / NPB (30nm) / BAlq (10nm ) / Alq 3 (10nm) / Mg:Ag(90nm)

[0065] The preparation method is as follows:

[0066] (1) Utilize detergent, ethanol solution and deionized water to ultrasonically clean the anode substrate, and dry it with dry nitrogen after cleaning;

[0067] (2) Ultr...

Embodiment 2

[0074] Such as figure 1 As shown, the organic functional layers in the device structure include a hole transport layer 3, a light emitting layer 4 and an electron transport layer 5, wherein the light emitting layer 4 is a blue light emitting layer or a green light emitting layer respectively.

[0075] The material of the hole transport layer of the device is NPB, and the material of the light emitting layer is BAlq or Alq 3 , the electron transport material is Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0076] Glass substrate / ITO / {3,4-polyethylenedioxythiophene / polystyrenesulfonic acid / 3,4-polyethylenedioxythiophene nanoparticles (particle size 30nm) / NPB (30nm) / BAlq (10nm ) / Alq 3 (10nm) / Mg:Ag(90nm)

[0077] The manufacturing process of the device is the same as that of Embodiment 1

Embodiment 3

[0079] Such as figure 1 As shown, the organic functional layers in the device structure include a hole transport layer 3, a light emitting layer 4 and an electron transport layer 5, wherein the light emitting layer 4 is a blue light emitting layer or a green light emitting layer respectively.

[0080] The material of the hole transport layer of the device is NPB, and the material of the light emitting layer is BAlq or Alq 3 , the electron transport material is Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0081] Glass substrate / ITO / {3,4-polyethylenedioxythiophene / polystyrenesulfonic acid / polypyrrole nanoparticles (particle size 20nm) / NPB(30nm) / BAlq(10nm) / Alq 3 (10nm) / Mg:Ag(90nm)

[0082] The manufacturing process of the device is the same as that of Embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com