Manufacture method of VDMOS device with irradiation resistance

A device manufacturing method and anti-irradiation technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unfavorable anti-single event grid penetration, etc., to improve the anti-single event grid penetration ability and reduce the electric field , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

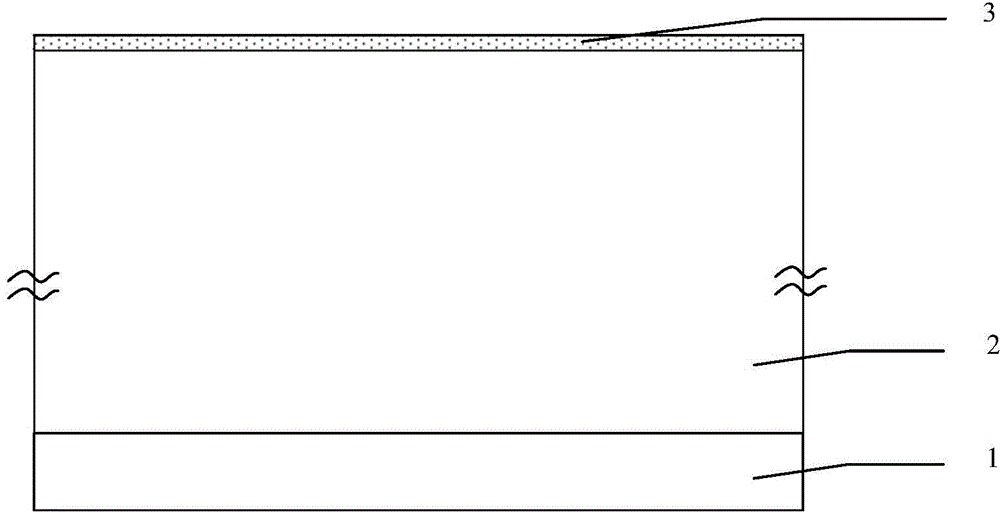

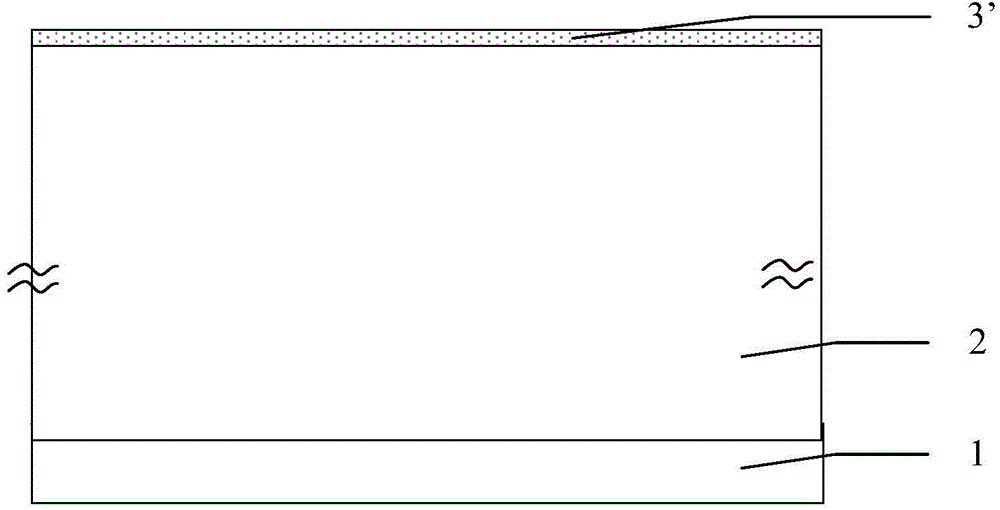

[0030] The invention improves on the basis of the traditional VDMOS manufacturing process, so that the VDMOS device has the anti-radiation performance. The specific principle is: the silicon dioxide gate oxide layer doped with aluminum impurities is used as the gate dielectric of the device, and the doped aluminum impurities are used as electron capture centers to reduce the accumulation of positive charges during irradiation and improve the ability to resist total dose radiation. At the same time, the dielectric constant of the gate medium is increased, the electric field in the gate medium is reduced when the device is irradiated, and the ability of the device to resist single-event gate breakdown is improved.

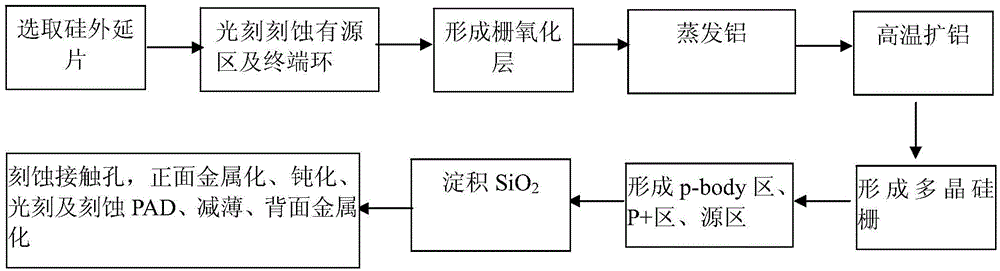

[0031] Concrete flow process of the present invention is as figure 1 As shown, an example is given to illustrate the specific implementation steps as follows:

[0032] (1) Choose a silicon epitaxial wafer with a crystal orientation of and a structure of N+N-, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com