Preparation method of CsPbI3 thin film

A technology of thin film and single crystal silicon, which is applied in the field of preparation of CsPbI3 thin film, can solve the problems of complex preparation method and low film quality, and achieve the effect of simple preparation method, compatible preparation process and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

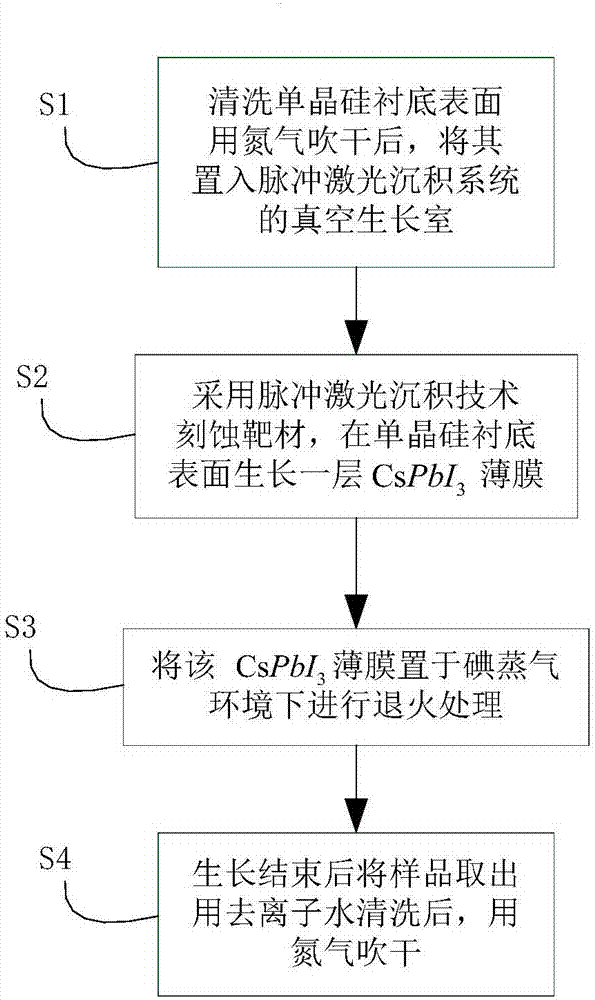

[0033] a CsPbI 3 Thin film preparation method, using laser pulse deposition technology to etch CsPbI 3 Target material, all-inorganic CsPbI prepared under vacuum conditions 3 Perovskite film, that is, the target is placed in the vacuum growth chamber of the pulsed laser deposition system, and the high-power pulsed laser is used to etch CsPbI at high temperature 3 The target material forms a plasma plume, undergoes adiabatic expansion of the plasma, and finally directional diffuses to the silicon substrate to nucleate and grow, forming CsPbI 3 film.

[0034] Such as figure 1 As shown, it specifically includes the following steps:

[0035] S1: Clean the surface of the single crystal silicon substrate, dry it with nitrogen, and put it into the vacuum growth chamber of the pulsed laser deposition system;

[0036] Perform standard RCA cleaning on the monocrystalline silicon substrate to remove organic matter, metal ion impurities and dust on the surface;

[0037] S2: The targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com