Electronic controller clamping device

An electronic controller and clamping device technology, applied in program control devices, workpiece clamping devices, manufacturing tools, etc., can solve the problems of serious consumables, increase production costs, easy wear of test probes, etc. Improved stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

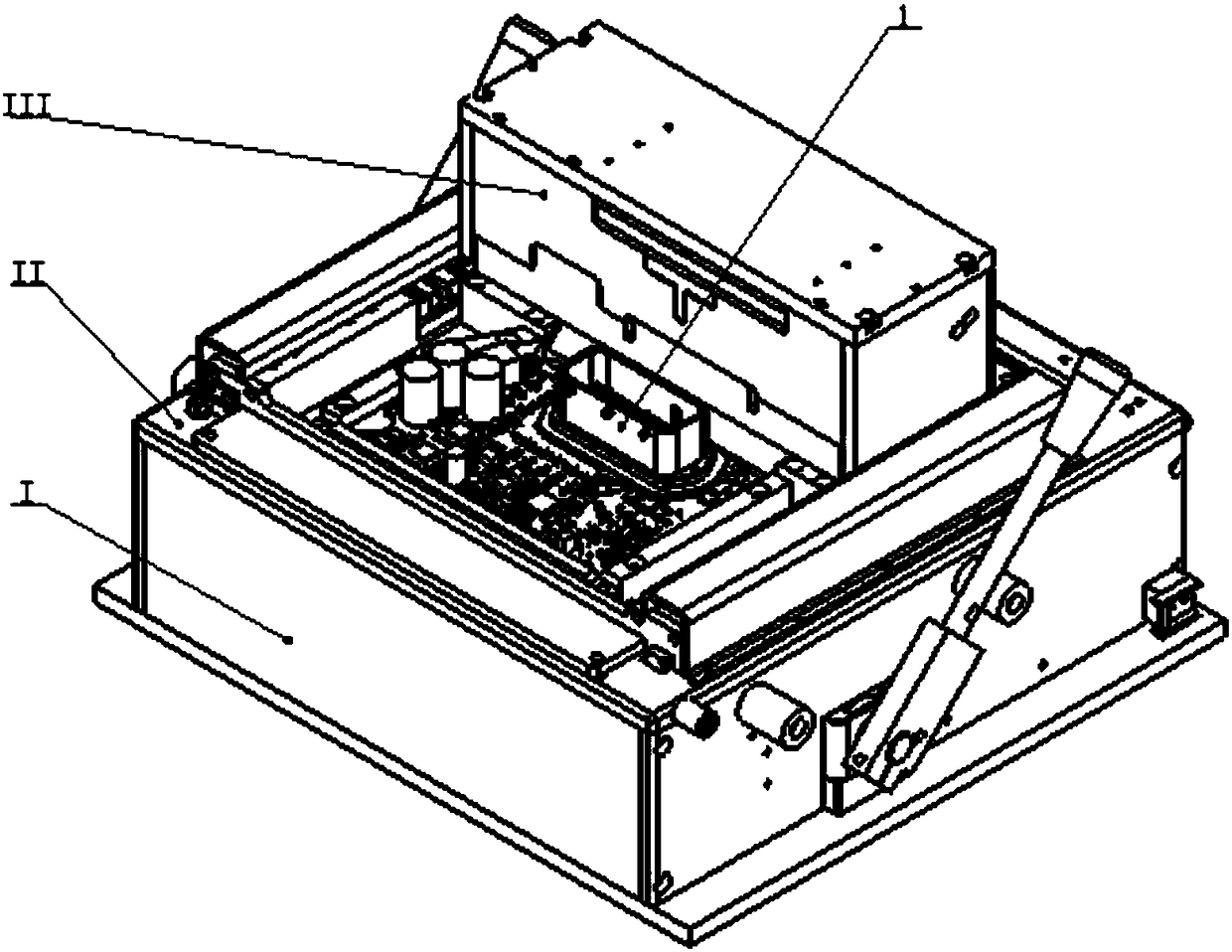

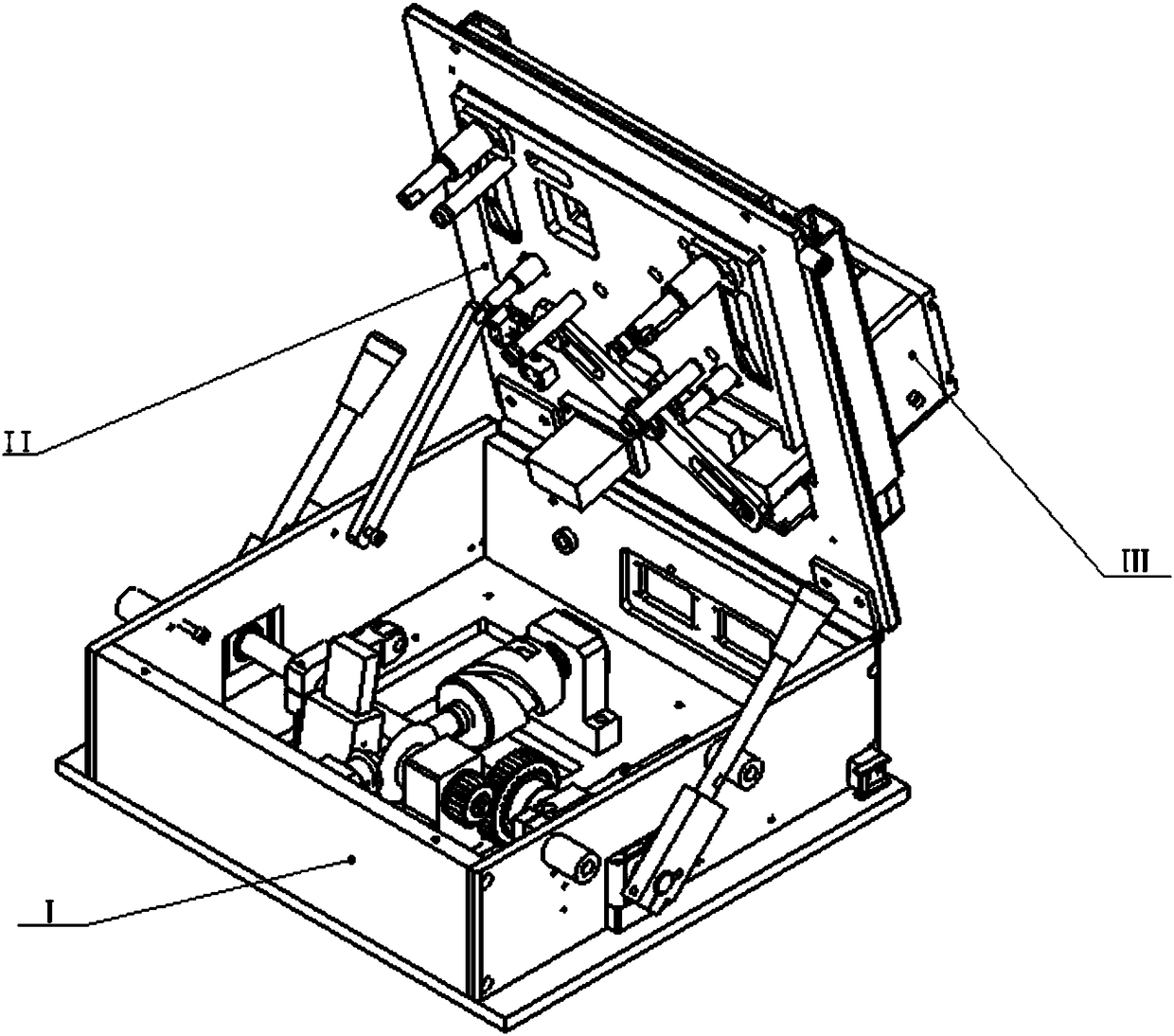

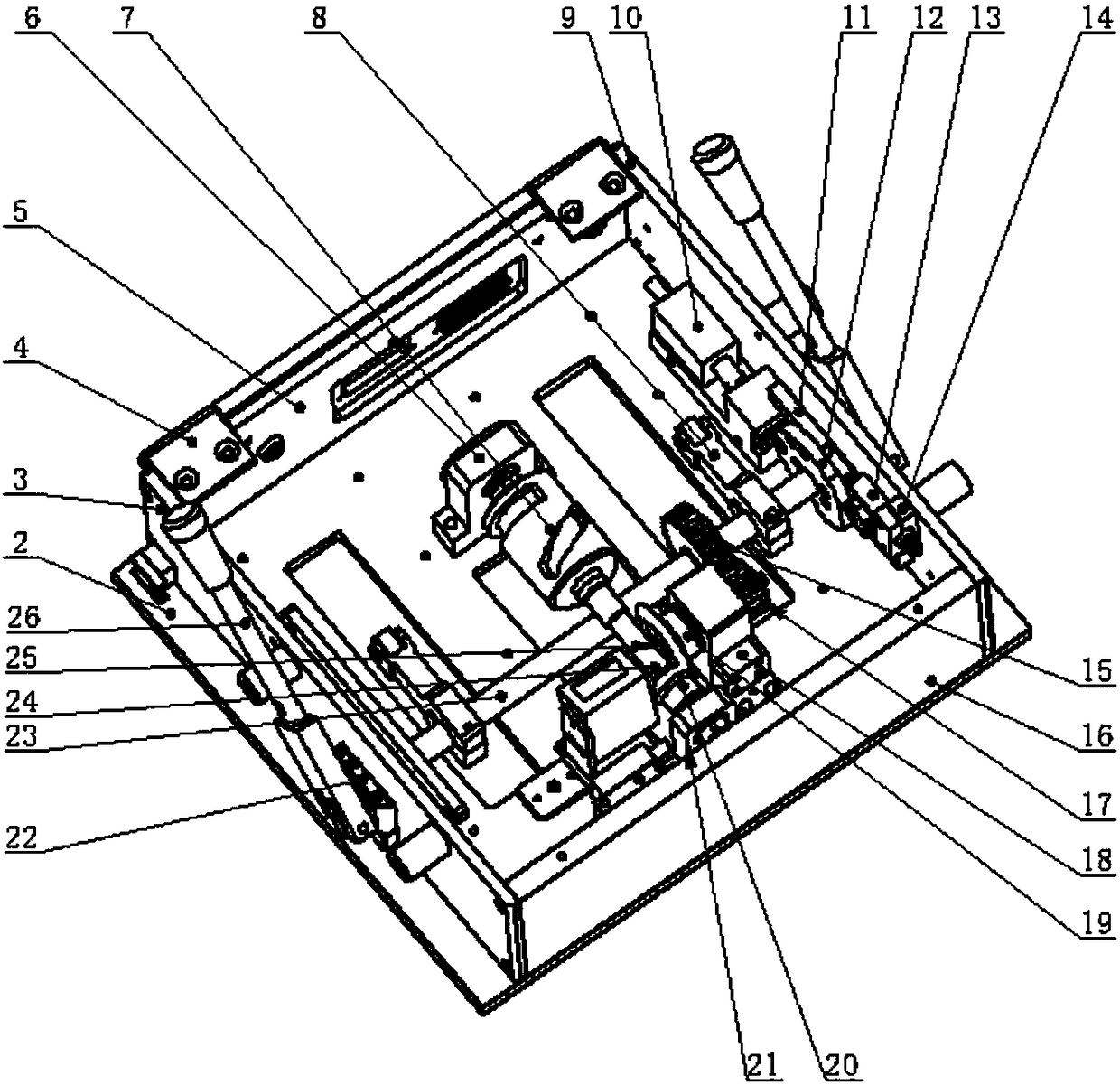

[0111] The electronic controller clamping device provided by the present invention includes: an upper case body, a lower case body, a handle rotation mechanism, a gear transmission mechanism, a plane cam mechanism, a space cam mechanism, a link mechanism, a probe floating mechanism and a product positioning assembly;

[0112] The handle rotation mechanism, the gear transmission mechanism and the space cam mechanism are arranged in the lower box body, and the plane cam mechanism, the link mechanism, the product positioning assembly and the probe floating mechanism are arranged in the upper box body;

[0113] The handle rotation mechanism is connected with the gear transmission mechanism and the plane cam mechanism, the gear transmission mechanism is connected with the space cam mechanism, the space cam mechanism is connected with the product positioning component, and the product positioning component is connected with the link mechanism and the probe floating mechanism.

[0114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com