MOF (Metal Organic Framework) porous adsorption material as well as preparation method and application thereof

A porous adsorption material and porous material technology, applied in the field of MOF porous adsorption material and its preparation, can solve the problems of poor adsorption efficiency of low-concentration iodine, high cost of precious metals, and susceptibility to humidity interference, etc., to achieve abundant reserves, controllable cost, The effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]The invention discloses a method for preparing a MOF porous material for capturing gas and liquid radioactive iodine, which comprises the following steps:

[0045] (1) Pb 2+ The soluble salt and 5-(4-pyridine) isophthalic acid were weighed respectively according to the molar ratio of 0.5:1;

[0046] (2) 5-(4-pyridine) isophthalic acid was stirred and dissolved in 8mL N,N-dimethylacetamide solution, Pb 2+ The soluble metal salt of is stirred and dissolved in 1mL N,N-dimethylacetamide solution, and then the two solutions are mixed to obtain a mixed solution;

[0047] (3) The reaction mother liquid was reacted at 100° C. for 24 hours at a constant temperature, cooled to room temperature, and the precipitate was filtered and washed with N,N-dimethylacetamide to obtain colorless transparent strip crystals.

Embodiment 2

[0049] The invention discloses a method for preparing a MOF porous material for capturing gas and liquid radioactive iodine, which comprises the following steps:

[0050] (1) Pb 2+ The soluble salt and 5-(4-pyridine) isophthalic acid were weighed respectively according to the molar ratio of 1:1;

[0051] (2) 5-(4-pyridine) isophthalic acid was stirred and dissolved in 10mL N,N-dimethylacetamide solution, Pb 2+ The soluble metal salt of is stirred and dissolved in 2mL N,N-dimethylacetamide solution, and then the two solutions are mixed to obtain a mixed solution;

[0052] (3) The reaction mother liquid was reacted at 120° C. for 48 hours at a constant temperature, cooled to room temperature, and the precipitate was filtered and washed with N,N-dimethylacetamide to obtain colorless transparent strip crystals.

Embodiment 3

[0054] The invention discloses a method for preparing a MOF porous material for capturing gas and liquid radioactive iodine, which comprises the following steps:

[0055] (1) Pb 2+ The soluble salt and 5-(4-pyridine) isophthalic acid are weighed respectively according to the molar ratio of 2:1;

[0056] (2) 5-(4-pyridine) isophthalic acid was stirred and dissolved in 12mL N,N-dimethylacetamide solution, Pb 2+ The soluble metal salt of is stirred and dissolved in 3mL N,N-dimethylacetamide solution, and then the two solutions are mixed to obtain a mixed solution;

[0057] (3) The reaction mother liquid was reacted at 140° C. for 96 hours at a constant temperature, cooled to room temperature, and the precipitate was filtered and washed with N,N-dimethylacetamide to obtain colorless transparent strip crystals.

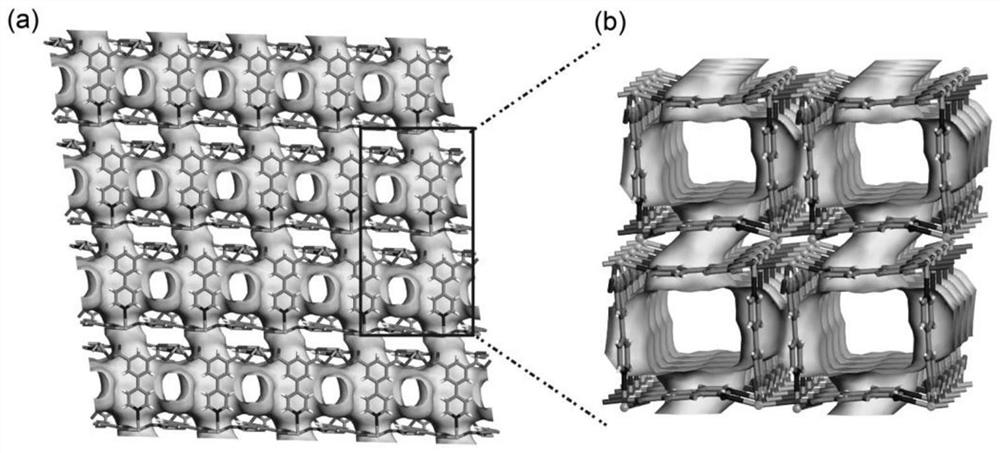

[0058] A kind of MOF porous adsorption material that the present invention prepares, chemical formula is [Pb 2 (pia) 2 (DMA)]·DMA; wherein, pia is 5-(4-pyridine)isopht...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com