Anti-icing coating and anti-icing material, and preparation methods thereof

An anti-icing and coating technology, applied in chemical instruments and methods, coatings, other chemical processes, etc., can solve the problem that the anti-icing coating needs to be improved, affects the photothermal conversion efficiency, and reduces the photothermal deicing efficiency, etc. To avoid the weakening of the photothermal characteristics, improve the anti-icing efficiency and the durability of the photothermal characteristics, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

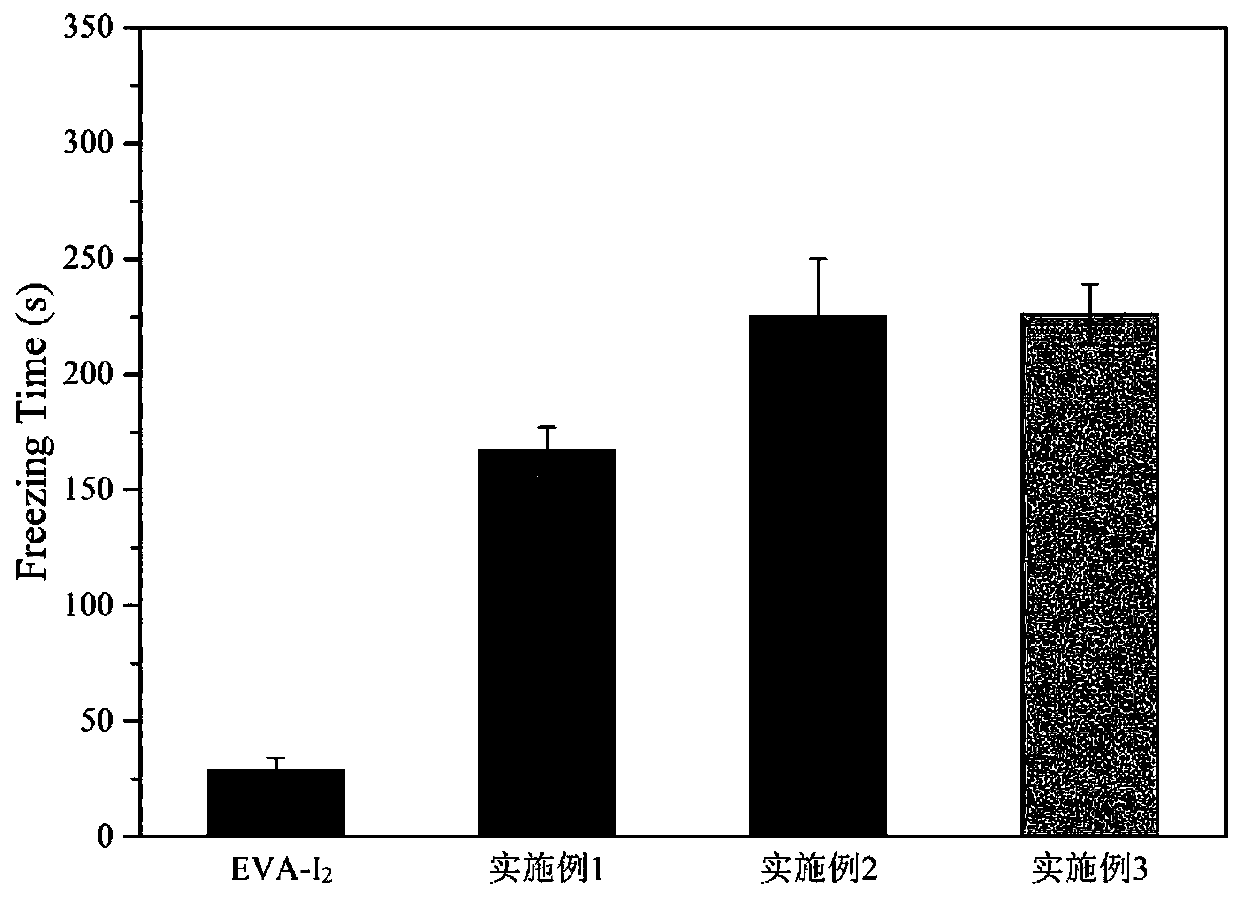

Embodiment 1

[0043] A kind of anti-icing paint, its preparation method is as follows:

[0044] Hydrophobic fumed silica (SiO 2, Shanghai Aladdin Biochemical Technology Co., Ltd., particle size: 7-40 nanometers, purity: 99.8%) 400 mg, silicon carbide micropowder (SiC, produced by Shandong Jinmeng New Material Company, 2000 mesh, purity: 95%) 100 mg , joined in 30 milliliters of absolute ethanol, measure 3 milliliters of ethyl orthosilicate (produced by Shanghai Macklin Biochemical Company, purity: 98%), perfluorodecyltrimethoxysilane (produced by Shanghai Macklin Biochemical Company) , purity: 97%) 100 microliters join in above-mentioned dehydrated alcohol, add glacial acetic acid and adjust pH to be 3~5 (the purpose of adjusting pH is to make perfluorodecyltrimethoxysilane hydrolyze more fully), ultrasonic dispersion 30min The resulting suspension is the anti-icing coating.

[0045] A kind of anti-icing material, its preparation method is as follows:

[0046] (1) take elemental iodine (...

Embodiment 2

[0053] A kind of anti-icing paint, its preparation method is as follows:

[0054] Hydrophobic fumed silica (SiO 2 , Shanghai Aladdin Biochemical Technology Co., Ltd., particle size: 7-40 nanometers, purity: 99.8%) 400 mg, silicon carbide micropowder (SiC, produced by Shandong Jinmeng New Material Company, 2000 mesh, purity: 95%) 200 mg , joined in 30 milliliters of absolute ethanol, measure 3 milliliters of ethyl orthosilicate (produced by Shanghai Macklin Biochemical Company, purity: 98%), perfluorodecyltrimethoxysilane (produced by Shanghai Macklin Biochemical Company) , purity: 97%) 100 microliters joins in above-mentioned absolute ethanol, adds glacial acetic acid and adjusts pH value to be 3~5, the suspension that ultrasonic dispersion 30min obtains, namely described anti-icing coating.

[0055] A kind of anti-icing material, its preparation method is as follows:

[0056] (1) same as embodiment 1 step, obtain EVA-I 2 matrix;

[0057] (2) Spray the prepared anti-icing ...

Embodiment 3

[0063] A kind of anti-icing paint, its preparation method is as follows:

[0064] Hydrophobic fumed silica (SiO 2 , Shanghai Aladdin Biochemical Technology Co., Ltd., particle size: 7-40 nanometers, purity: 99.8%) 400 mg, silicon carbide micropowder (SiC, produced by Shandong Jinmeng New Material Company, 2000 mesh, purity: 95%) 600 mg , joined in 30 milliliters of absolute ethanol, measure 3 milliliters of ethyl orthosilicate (produced by Shanghai Macklin Biochemical Company, purity: 98%), perfluorodecyltrimethoxysilane (produced by Shanghai Macklin Biochemical Company) , purity: 97%) 100 microliters joins in above-mentioned absolute ethanol, adds glacial acetic acid and adjusts pH value to be 3~5, the suspension liquid that ultrasonic dispersion obtains for 30min, namely described anti-icing coating.

[0065] A kind of anti-icing material, its preparation method is as follows:

[0066] (1) same as embodiment 1 step, obtain EVA-I 2 matrix;

[0067] (2) Spray the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

| Ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com