Automatic chip discharging and conveying device

A technology of automatic unloading and conveying device, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., to achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific examples.

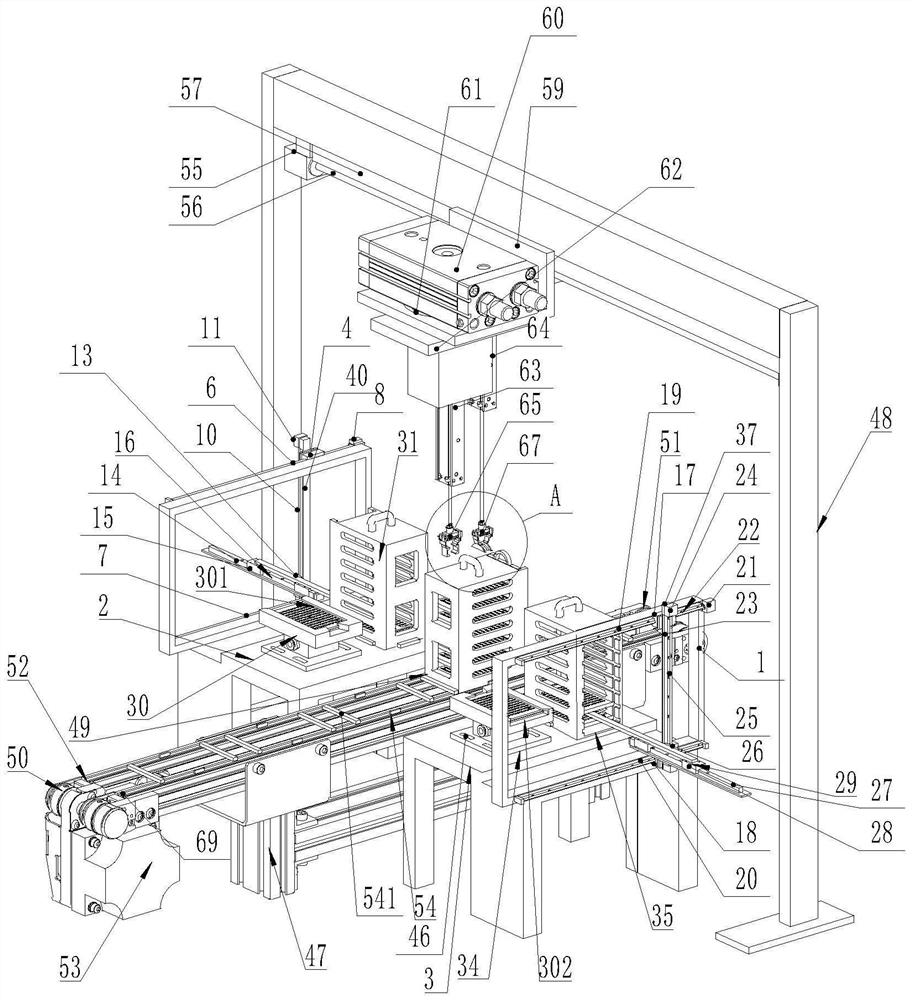

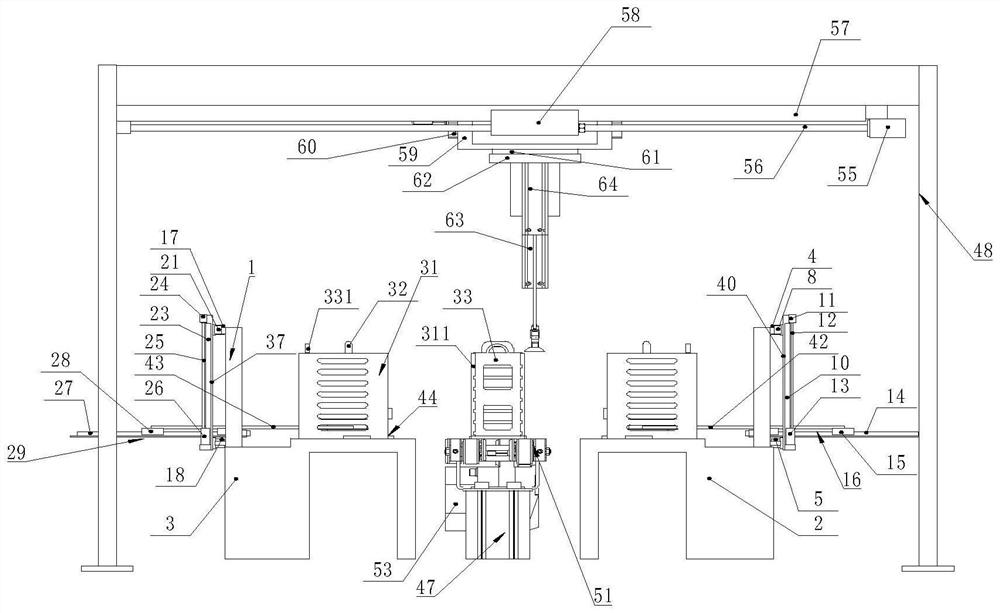

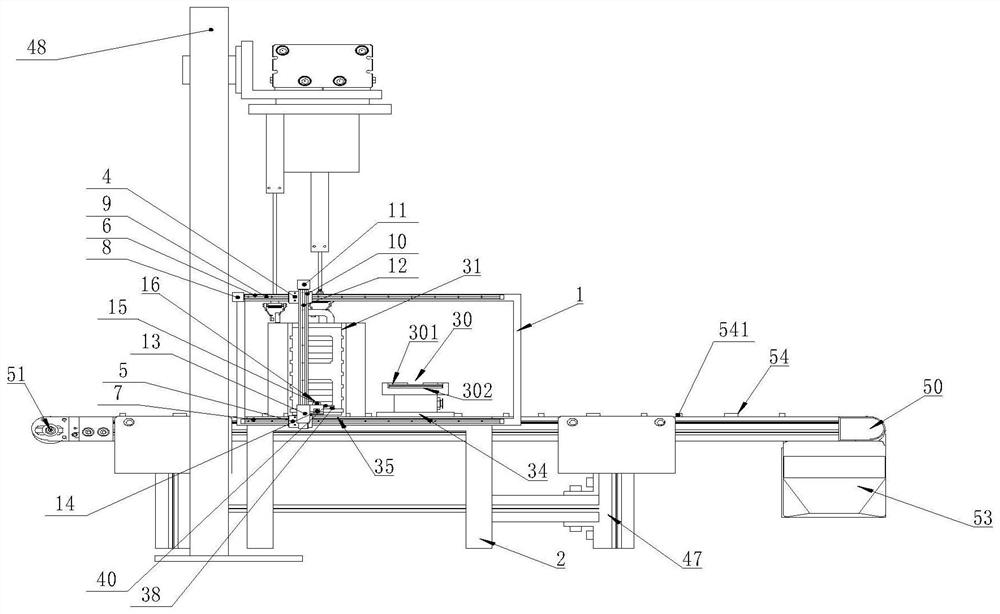

[0036] Such as Figure 1 to Figure 7 As shown, an automatic chip unloading and conveying device includes a chip carrier transfer device and a storage box transfer device, and the chip carrier transfer device includes an adsorption support frame 1, a carrier table 30, and a carrier storage box 31 and the workbench, the carrier table 30 and the carrier accommodating box 31 are respectively placed on the bonding station 34 and the adsorption station 35 on the workbench, the carrier table 30 is provided with an opening groove 301, and the opening The feeding end of the groove 301 is provided with an assembly port 302 for easy extraction of the carrier; the carrier receiving box 31 is provided with several carrier receiving grooves 311 for inserting the carrier, and the adsorption support frame 1 is fixedly installed with An X guide rail extending along the horizontal X direction, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com