A hot pressing production line for door processing

A production line and thermoforming technology, which is applied in the direction of wood processing equipment, lamination, veneer presses, etc., can solve the problems of inability to realize automatic production of products, low production efficiency, and high labor intensity, so as to reduce labor costs and improve Production efficiency, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

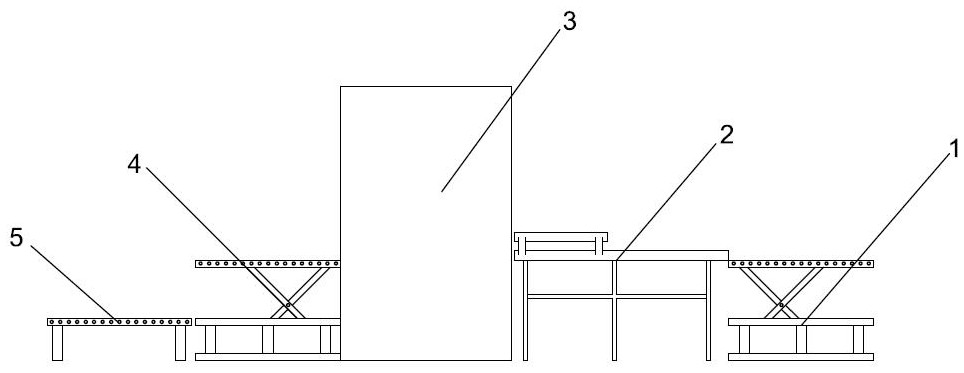

[0068] see Figure 1 to Figure 21 , the embodiment of the present invention provides a door processing hot-pressing production line, which is suitable for hot-pressing forming processing of film-coated back door products. The hot-pressing production line includes a feeding device 1, a pushing device 2, a hot-pressing machine body 3, Unloading device 4 and buffer platform 5.

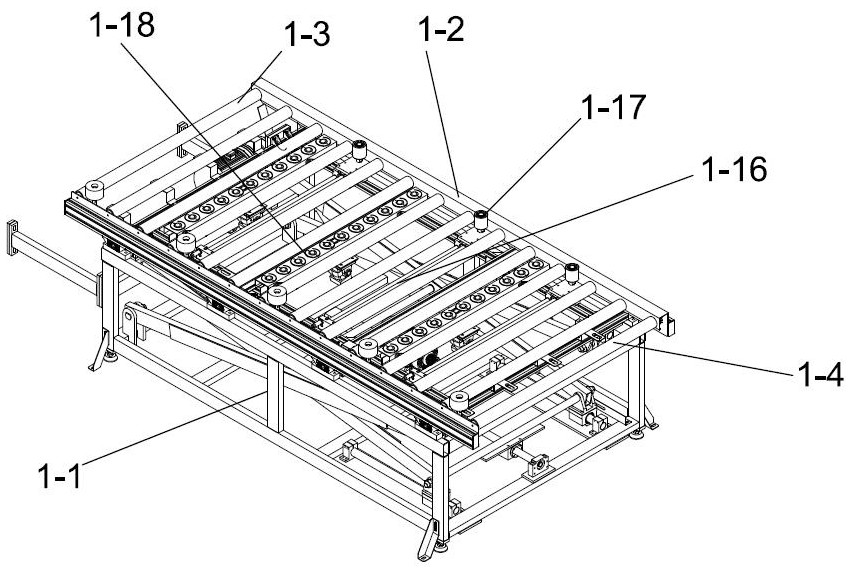

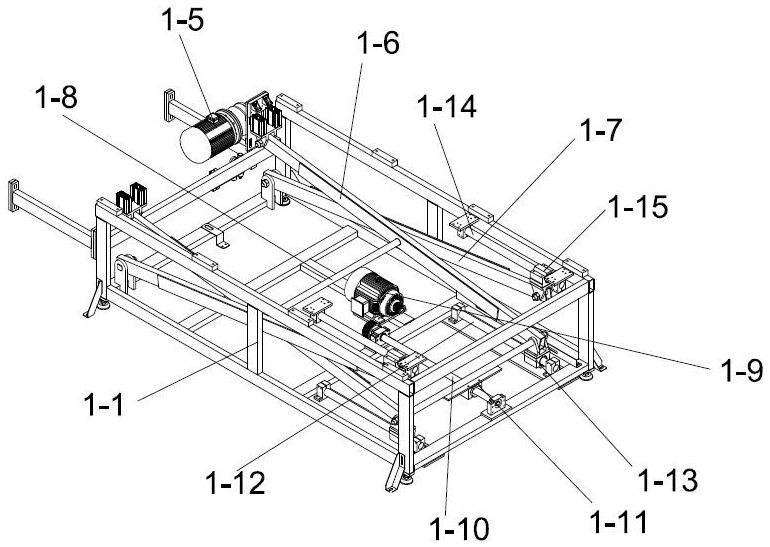

[0069] 1. Feeding device

[0070] 1) Material conveying and lifting

[0071] The feeding device 1 includes a mounting frame 1-1, the mounting frame 1-1 is provided with a liftable carrying frame 1-2, the two ends of the carrying frame 1-2 are raw material inlet and raw material outlet respectively, and the upper carrying frame 1-2 There is a conveying unit for conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com