Transmission chain control device for double-end edge bonding machine

A technology of transmission chain and control device, which is applied in the direction of wood processing appliances, household components, etc., to achieve the effects of automatic, fast and accurate positioning, high degree of automation, and stable and accurate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

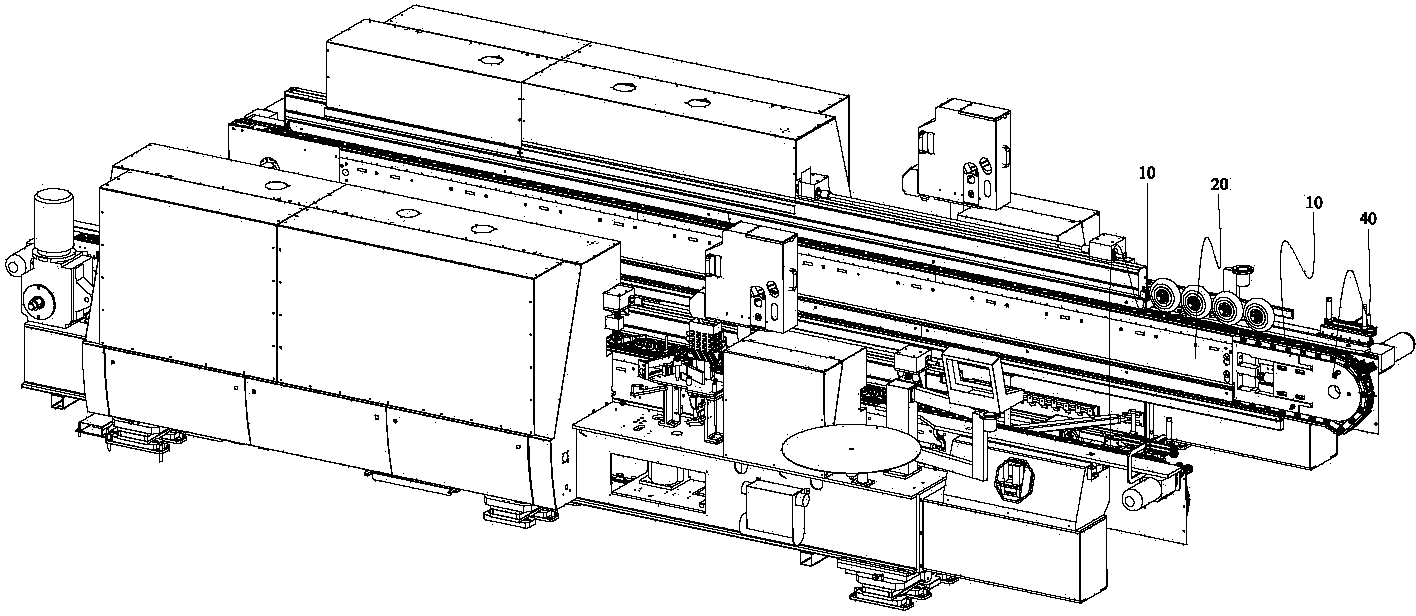

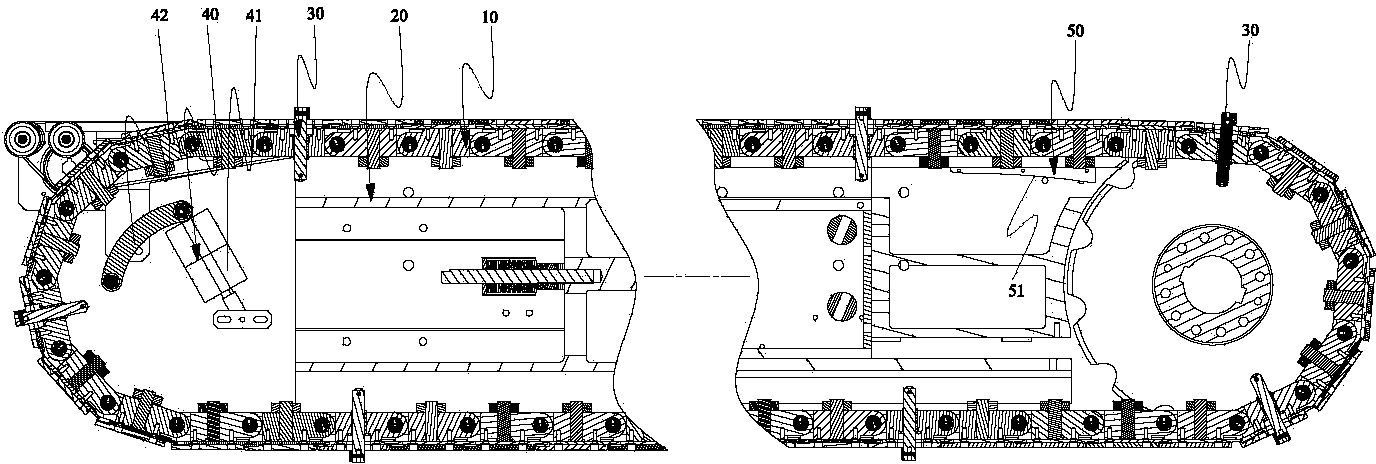

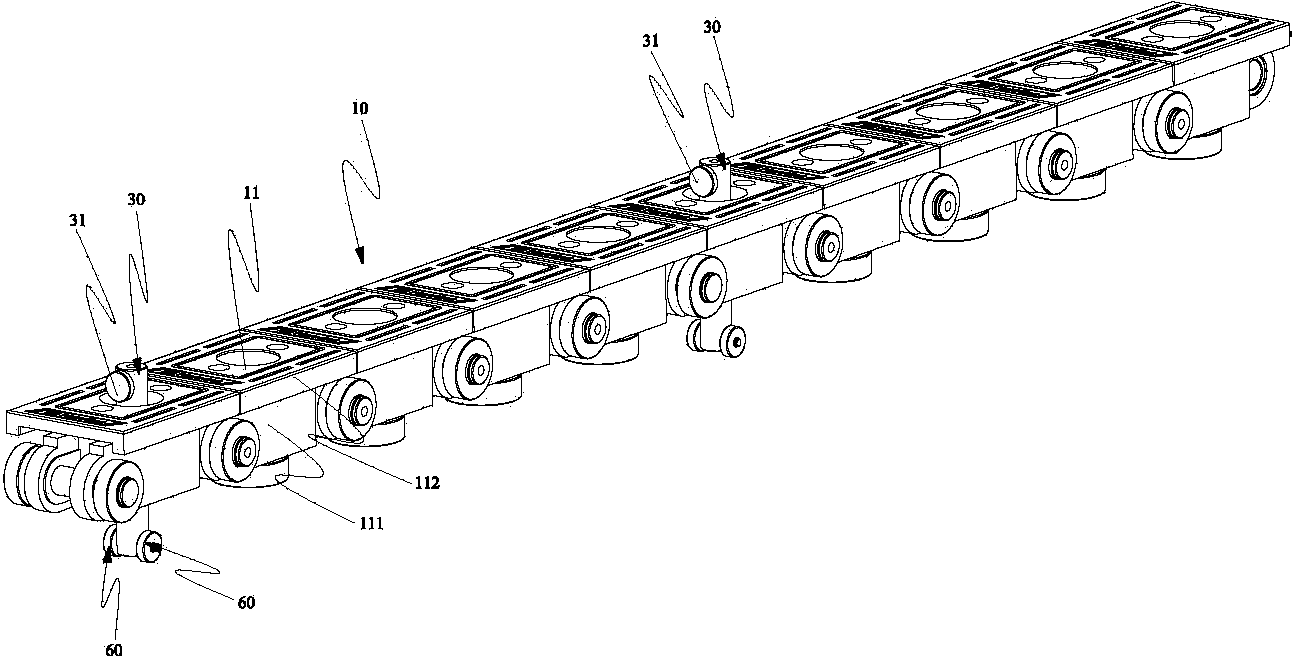

[0040] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including two transmission chains 10.

[0041] The two transmission chains 10 are arranged on the frame 20 of the double-end edge banding machine in parallel with each other at left and right intervals. Each transmission chain 10 includes a plurality of chain blocks 11, and the plurality of chain blocks 11 are connected in series to form a ring. The transmission chain, and each transmission chain 10 is provided with a plurality of hook heads 30 that can be moved inside and outside at intervals, and the plurality of hook heads 30 move synchronously with the chain block 11. For the plurality of hook heads 30, each transmission chain The inside of the feed end of 10 is provided with a push-up mechanism 40 that urges the hook head 30 to extend outwards above the chain block 11, and is provided with a push-up mechanism 40 inside the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com