Automatic button finishing and feeding device for garment production

A technology of automatic sorting and feeding device, which is applied in the direction of cleaning methods, cleaning methods and utensils using liquids, textiles and papermaking, etc., can solve problems such as inefficiency, button feeding, affecting button buttoning and production, etc., to improve cleaning efficiency , The effect of accurate and stable conveying and improving the efficiency of buttoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

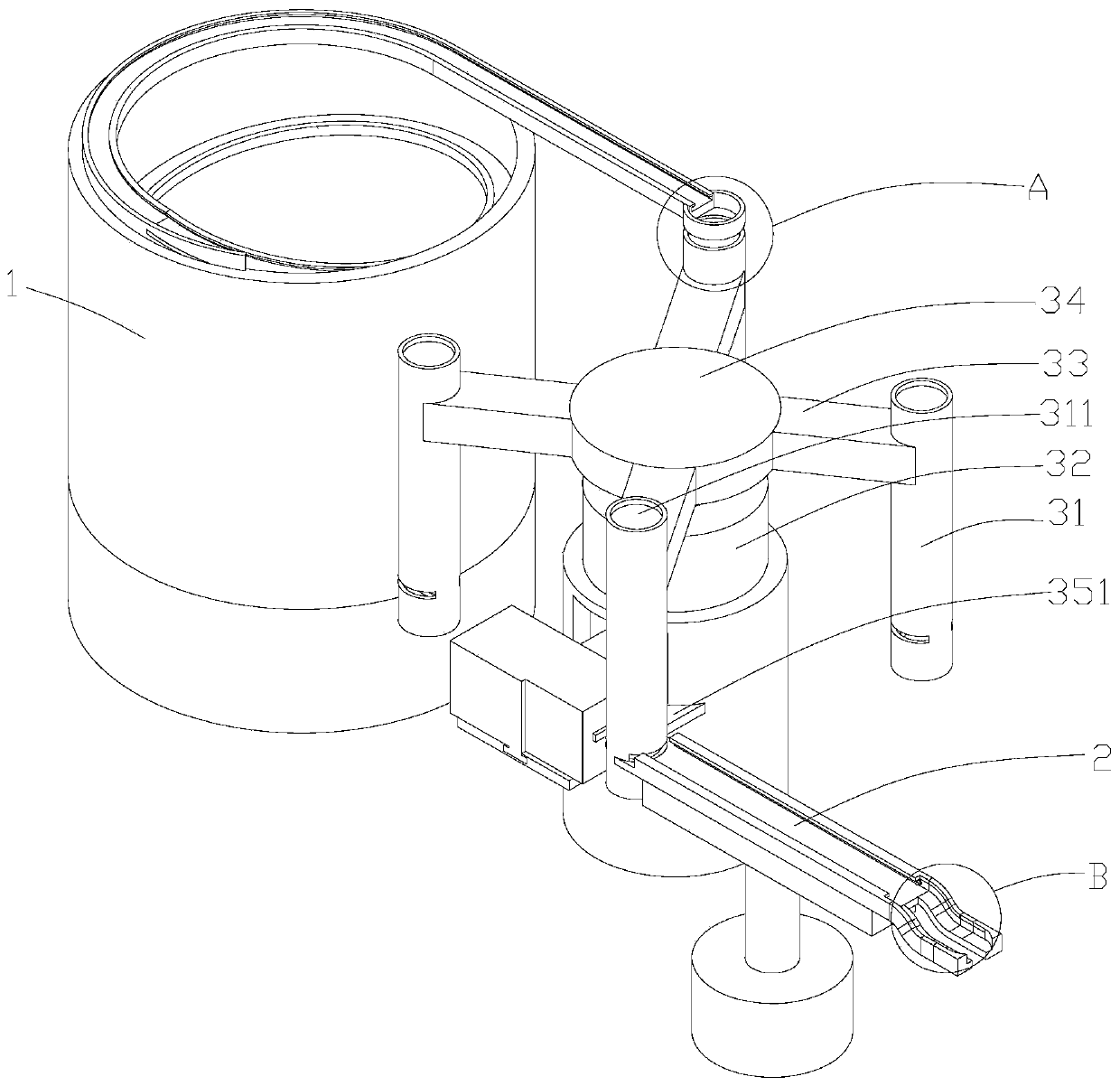

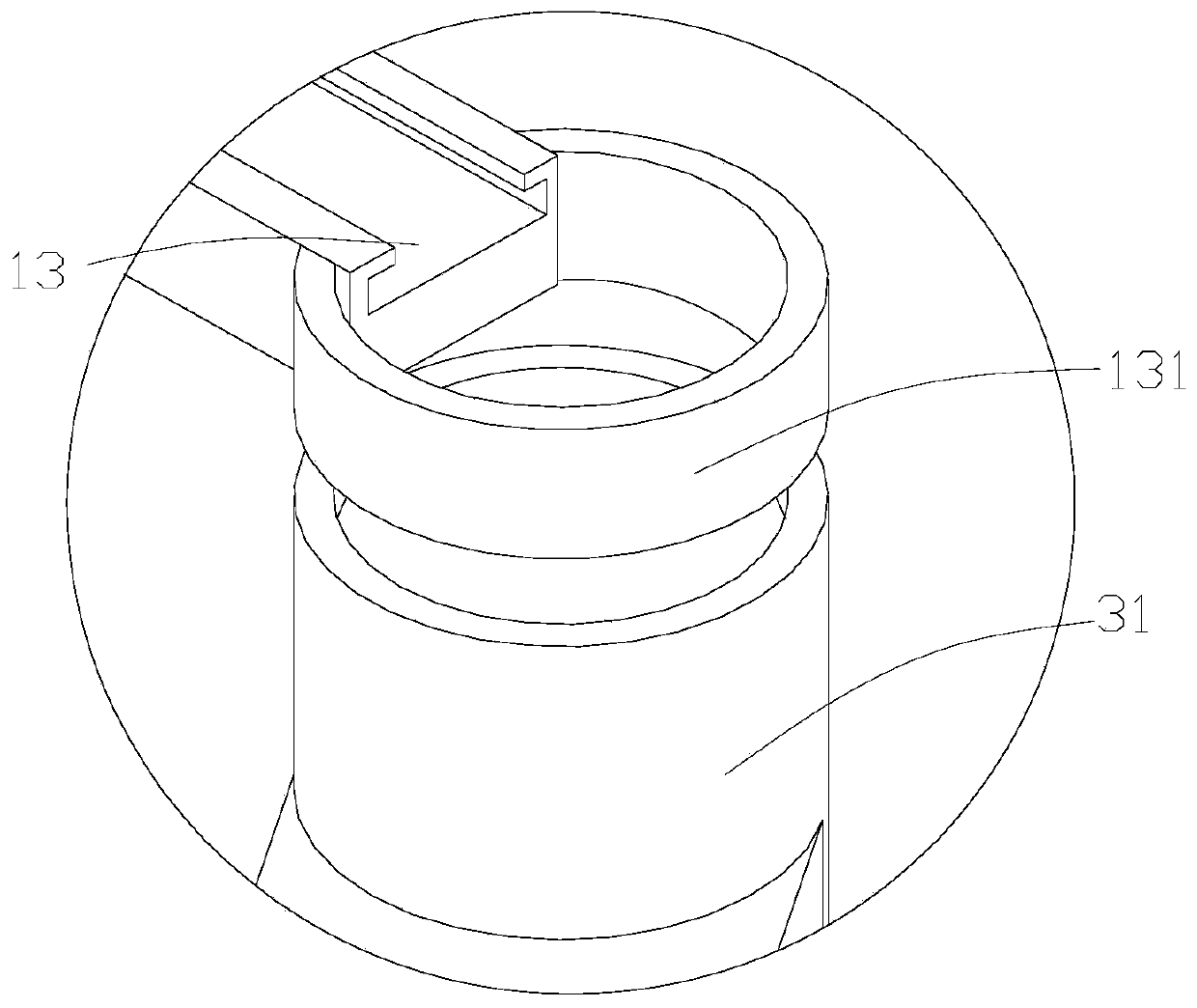

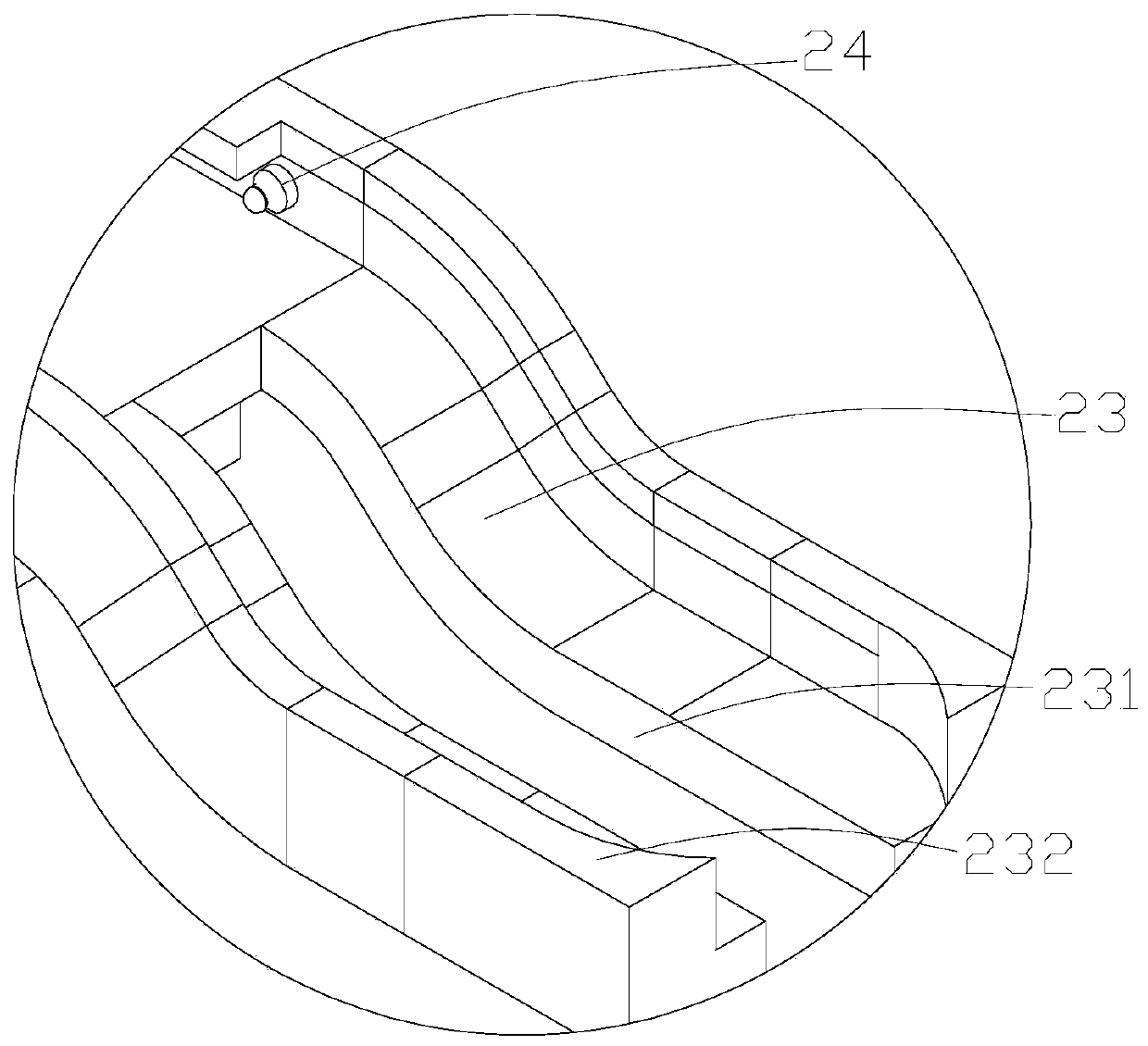

[0028] Such as Figure 1-14 As shown, a button automatic sorting and feeding device for garment production includes a storage barrel 1 for stacking unsorted buttons, a control panel 11 for moving and conveying the buttons in the storage barrel 1, and a Drive the first driving member 12 of the control panel 11, the described material cylinder 1 is provided with a screw conveying groove 13 for orderly conveying buttons, and also includes a feeding mechanism for orderly conveying buttons and for Buttons are transported to the delivery arm 2 of the button sewing machine for button sewing. Through the setting of the above structure, the buttons stacked together can be automatically sorted and transported through the spiral transport groove, so that the buttons can be transported in an orderly manner, so that It can effectively improve the efficiency of sorting and transporting buttons, and can sort and transport buttons in batches, effectively improving the feeding efficiency of bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com