Paper supply device for ink-jet printer

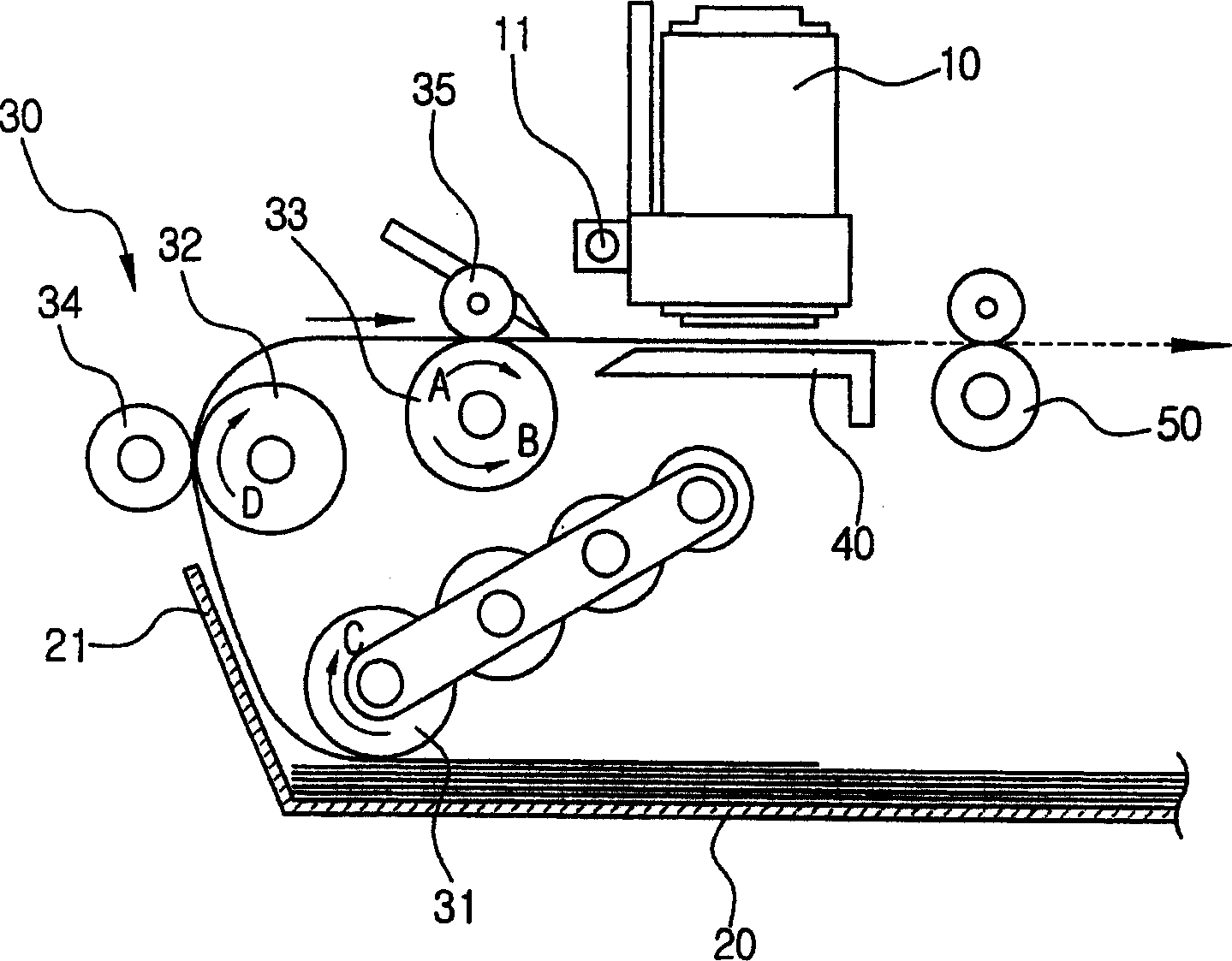

An inkjet printer and paper feeding device technology, applied in printing devices, printing presses, printing and other directions, can solve problems such as paper skew, reduced printing quality, inability to drive rollers 32 and feeding rollers 33 to smoothly transport paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

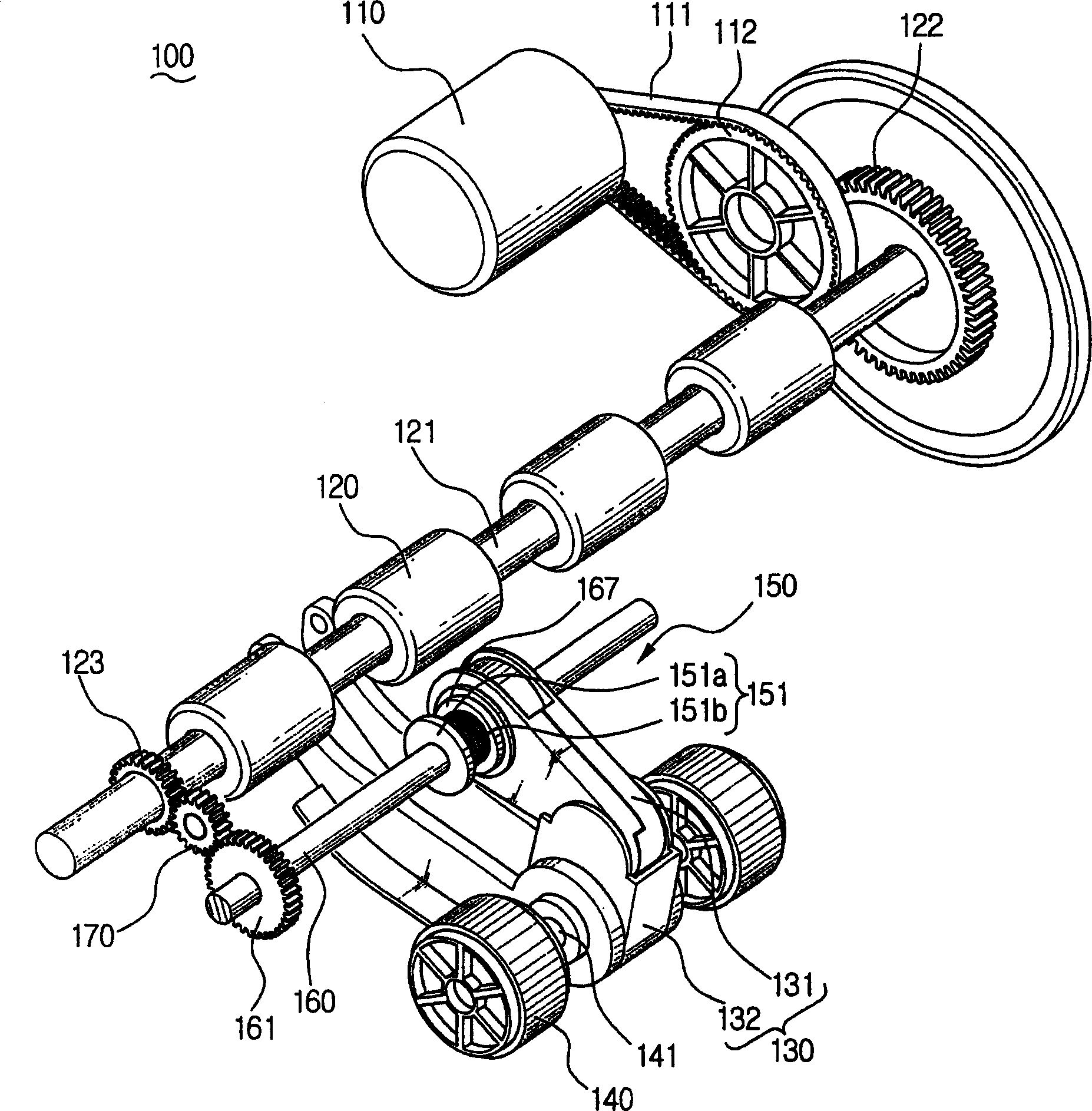

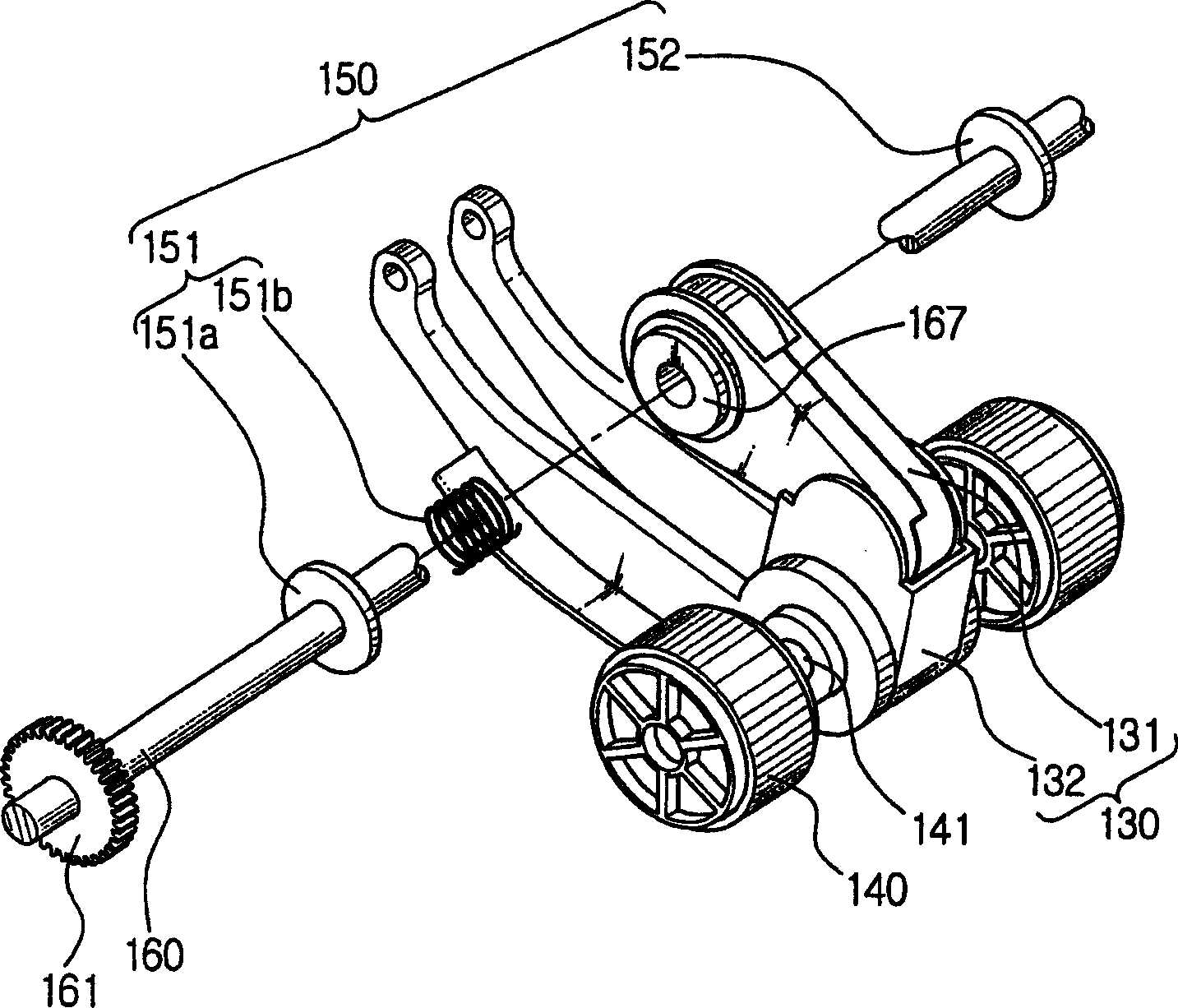

[0024] The paper feeding device of the inkjet printer according to the embodiment of the present invention will be described in more detail below with reference to the accompanying drawings. The same elements as in the prior art will be denoted by the same reference numerals.

[0025] Such as figure 2 As shown, the paper feeding device 100 of the inkjet printer according to the embodiment of the present invention includes a motor 110 , a feeding roller 120 , a coupling housing 130 , a pickup roller 140 and a clutch 150 .

[0026] The motor 110 is a power source for driving the supply roller 120 and the pickup roller 140, and is usually a DC motor. The motor 110 mainly moves the supply roller 120 to supply, so it is also called an LF motor. The motor 110 is connected to a timing belt 111 , and the timing belt 111 is connected to a reduction gear 112 .

[0027] The feed roller 120 directs the paper picked up by the pickup roller 140 toward the print head 10 ( figure 1 ) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com