Wet-process phosphoric acid extraction tower cleaning method

A wet-process phosphoric acid and extraction tower technology, applied in the directions of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the high quality and skill requirements, the complex fouling components of the extraction tower, and the cost of environmental protection treatment. High-level problems, to achieve the effect of improving cleaning efficiency and cleaning effect, reducing the risk of secondary pollution, and improving cleaning safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

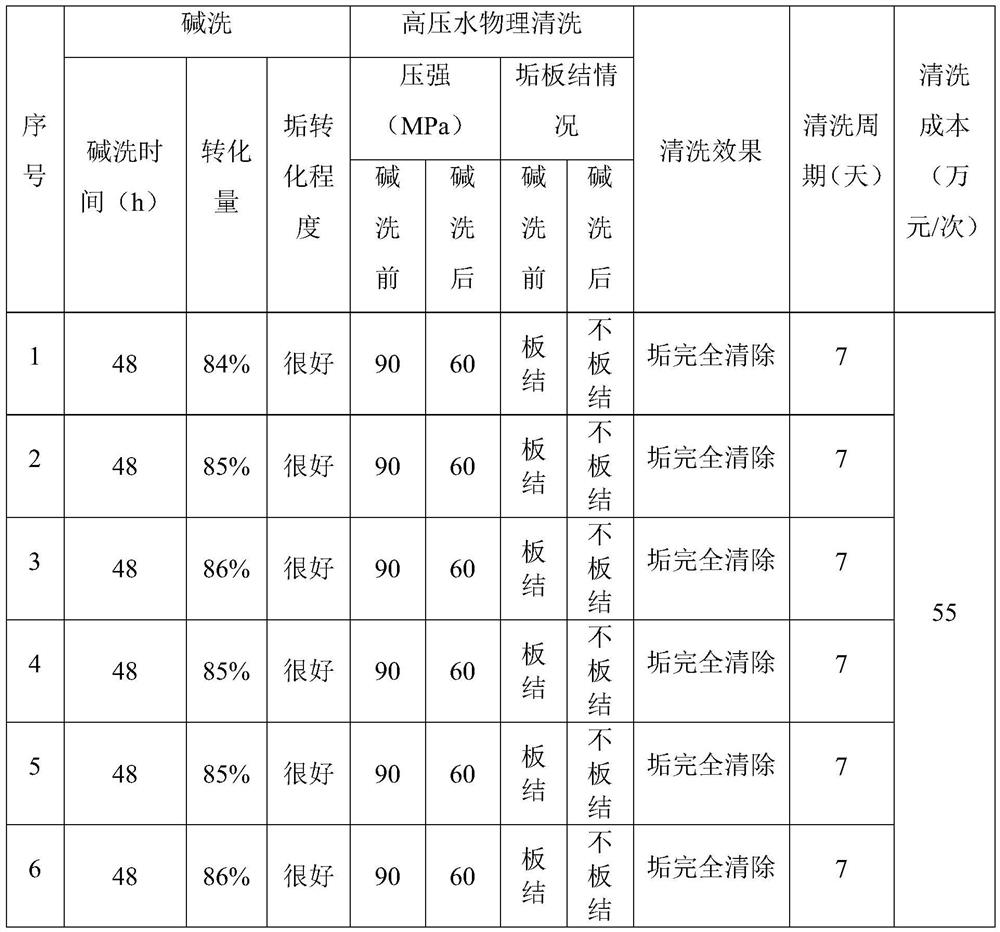

Embodiment 1

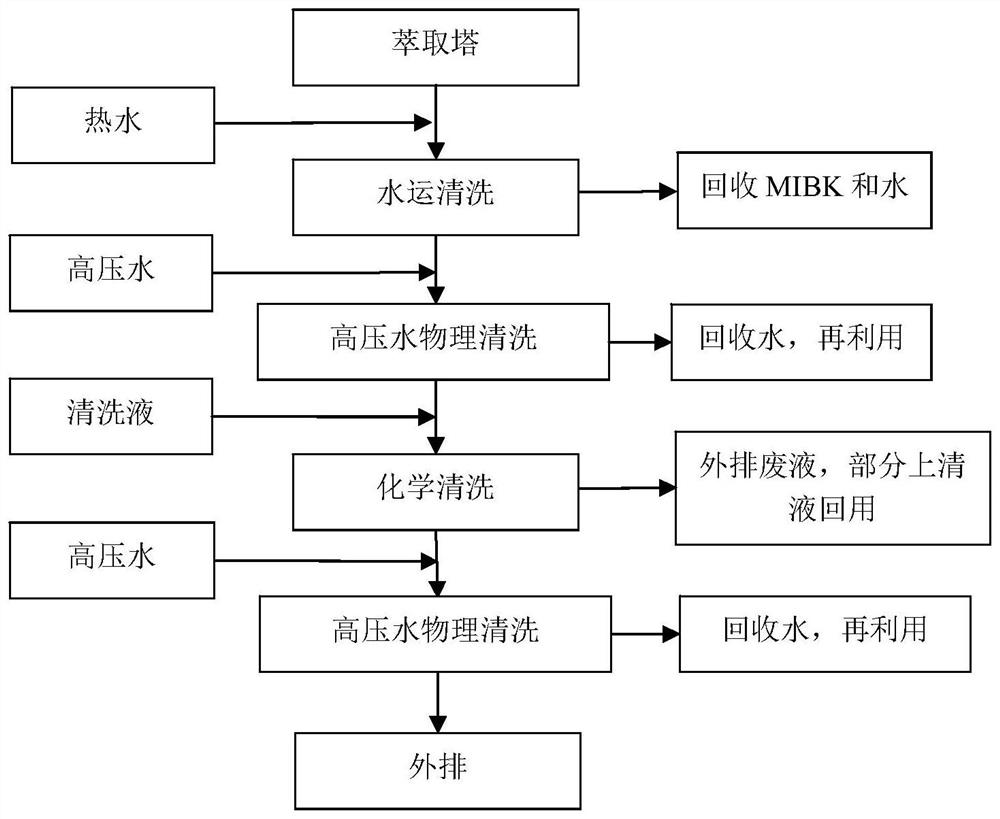

[0033] Cleaning method, process flow chart, wet phosphoric acid extract figure 1 As shown, including the following steps:

[0034] S1, the hot water of 80 ° C is introduced into the C200 extraction tower of the emptying to carry out water, and the time is 1 day. In this step, the pressure of hot water is controlled is 0.05 MPa ~ 0.08MPa, and the flow is ≥50m. 3 / h, from the top and sides of the extraction tower into the extraction column, which is mainly rushing from the top and downward, and is carried out inside the extracted tower to fix the extracted tower, and heat during the cleaning process. Water is circulated and cleaned to effectively dilute the acid residual acid in the entire tower body to reduce the consumption of subsequent alkaline dam, after the water is cleaned, the product obtained after cleaning water is discharged from the bottom of the extraction tower, solid-liquid separation, recovering methyl Isobuthenone (MIBK) and water, the resulting recovery water cont...

Embodiment 2

[0047] Cleaning method of a wet phosphoric acid extraction tower, including the following steps:

[0048] S1, the hot water of 80 ° C is introduced into the C200 extraction tower of the emptying to carry out water, and the time is 1 day. In this step, the pressure of hot water is controlled is 0.05 MPa ~ 0.08MPa, and the flow is ≥50m. 3 / h, from the top and sides of the extraction tower into the extraction column, which is mainly rushing from the top and downward, and is carried out inside the extracted tower to fix the extracted tower, and heat during the cleaning process. Water is circulated and cleaned to effectively dilute the acid residual acid in the entire tower body to reduce the consumption of subsequent alkaline dam, after the water is cleaned, the product obtained after cleaning water is discharged from the bottom of the extraction tower, solid-liquid separation, recovering methyl Isobuthenone (MIBK) and water, the resulting recovery water continues to be used to clean...

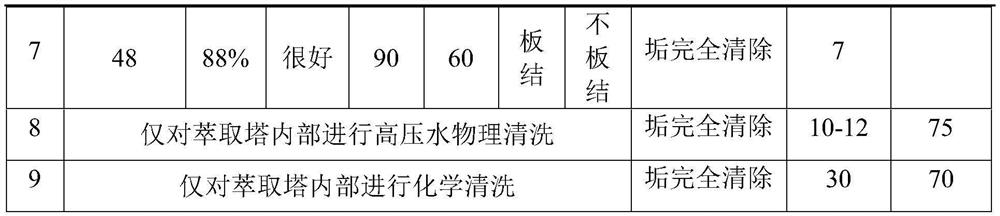

Embodiment 3

[0057] Cleaning method of a wet phosphoric acid extraction tower, including the following steps:

[0058] S1, the temperature of 50 ° C, 60 ° C, 70 ° C, 80 ° C, 90 ° C, 100 ° C, respectively, in the air-conditioned C200 extract, and the time is 1 day. In this step, the pressure of hot water is controlled is 0.05 MPa ~ 0.08MPa, and the flow is ≥50m. 3 / h, from the top and sides of the extraction tower into the extraction column, which is mainly rushing from the top and downward, and is carried out inside the extracted tower to fix the extracted tower, and heat during the cleaning process. Water is circulated and cleaned to effectively dilute the acid residual acid in the entire tower body to reduce the consumption of subsequent alkaline dam, after the water is cleaned, the product obtained after cleaning water is discharged from the bottom of the extraction tower, solid-liquid separation, recovering methyl Isobuthenone (MIBK) and water, the resulting recovery water continues to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com