Carbon-coated vanadium trioxide nanowire thin film with pod structure and preparation method of carbon-coated vanadium trioxide nanowire thin film with pod structure

A nano-vanadium trioxide and vanadium heptoxide nano-technology, which is applied in nanotechnology, nanotechnology, structural parts, etc., can solve problems such as difficulty in forming electrode films, and achieve improved charge and discharge performance, high yield, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

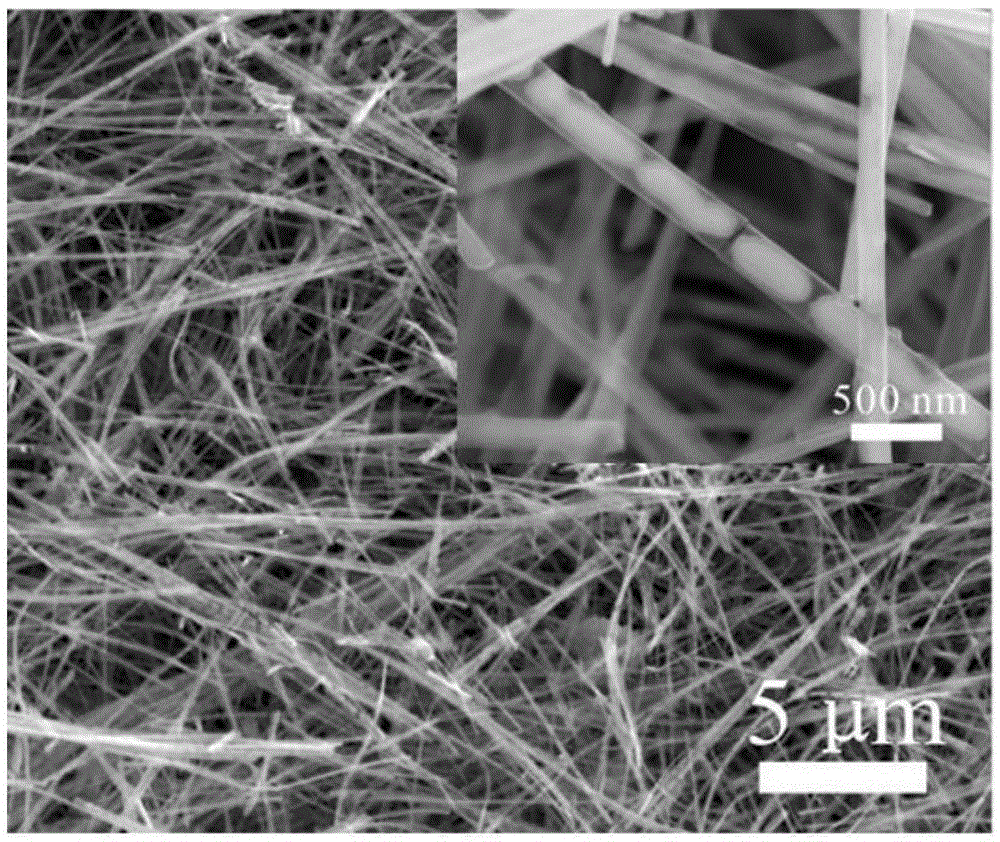

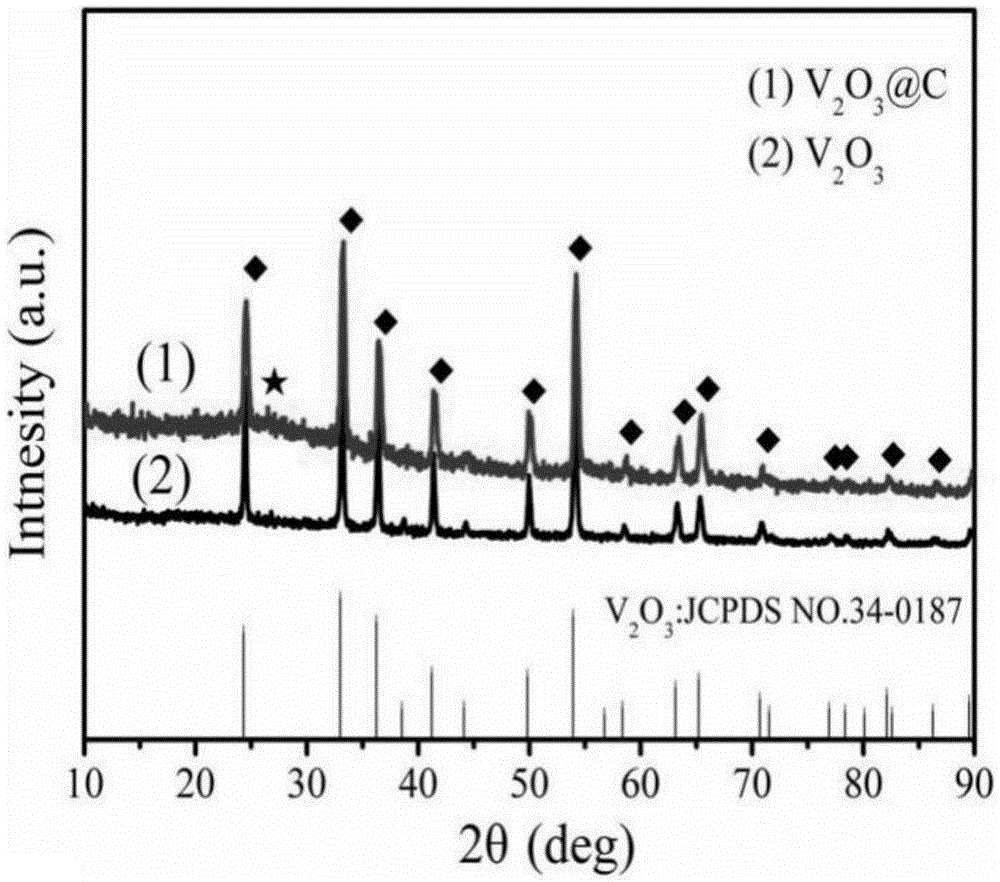

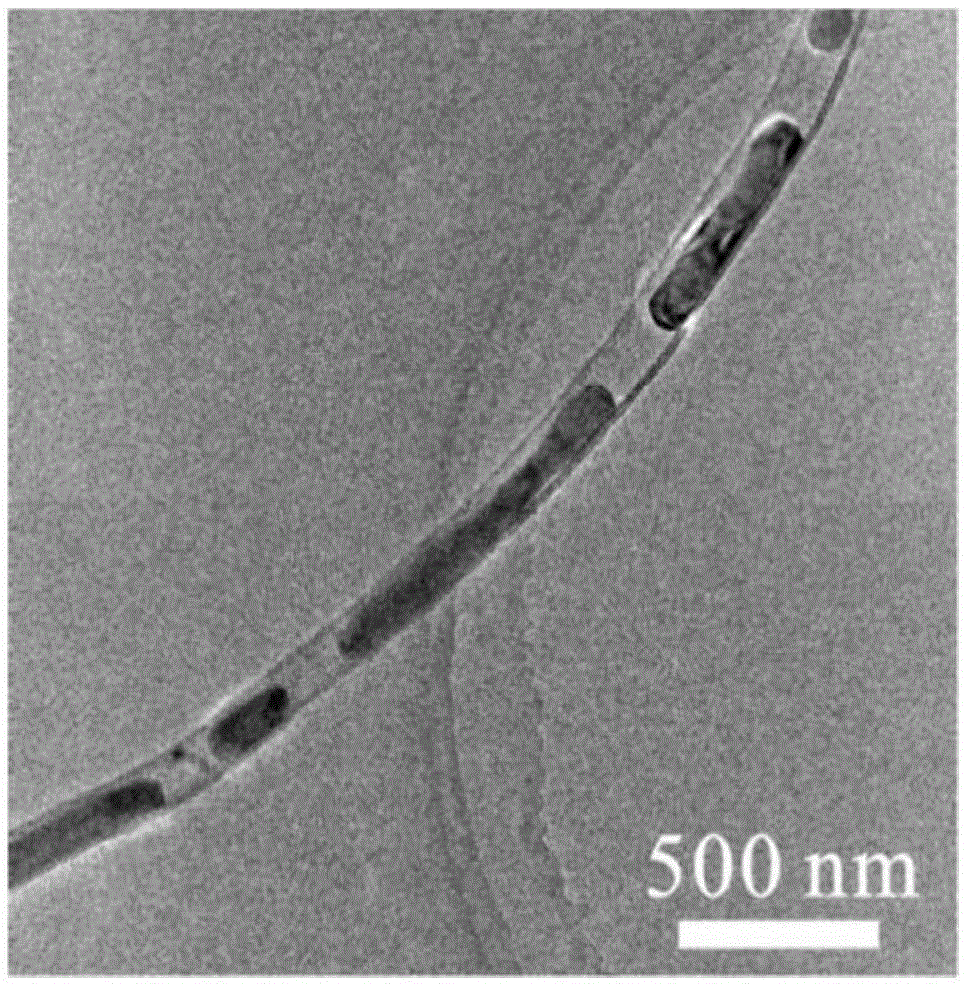

[0030] A carbon-coated vanadium trioxide nanowire film with a pod structure and a preparation method thereof. The preparation method comprises the following steps: First, take 0.524 g of vanadium pentoxide yellow powder and add 40 ml of distilled water, ultrasonically for about 30 minutes, mix thoroughly to form a yellow solution, then add 0.1443 g of dihydrate oxalic acid white powder, stir for 10 minutes, and dissolve the solution in water In a hot kettle, heat in an oven at 210°C for 72 hours, and finally wash and dry the obtained vanadium heptoxide nanowires; take 50 mg of the sample and add 40 ml of distilled water, place it under a stirrer with a rotation speed of 600 r / min, and stir for 1 hour. Obtain turquoise vanadium heptoxide ultra-long nanowire dispersion; then, take 40ml of the above-mentioned uniform dispersion, then add 50-200mg of glucose, stir for 10min, mix well, and finally pour the well-mixed above-mentioned solution into a 60ml hydrothermal kettle , raise ...

Embodiment 2

[0036] A carbon-coated vanadium trioxide nanowire film with a pod structure and a preparation method thereof. The preparation method comprises the following steps: First, take 0.524 g of vanadium pentoxide yellow powder and add 40 ml of distilled water, ultrasonically for about 30 minutes, mix thoroughly to form a yellow solution, then add 0.1443 g of dihydrate oxalic acid white powder, stir for 10 minutes, and dissolve the solution in water In a hot kettle, heat in an oven at 210°C for 72 hours, and finally wash and dry the obtained vanadium heptoxide nanowires; take 50 mg of the sample and add 40 ml of distilled water, place it under a stirrer with a rotation speed of 600 r / min, and stir for 1 hour. Obtain turquoise vanadium heptoxide ultra-long nanowire dispersion; then, take 40ml of the above-mentioned uniform dispersion, then add 50-200mg of glucose, stir for 10min, mix well, and finally pour the well-mixed above-mentioned solution into a 60ml hydrothermal kettle , raise ...

Embodiment 3

[0040] A carbon-coated vanadium trioxide nanowire film with a pod structure and a preparation method thereof. The preparation method comprises the following steps: First, take 0.524 g of vanadium pentoxide yellow powder and add 40 ml of distilled water, ultrasonically for about 30 minutes, mix thoroughly to form a yellow solution, then add 0.1443 g of dihydrate oxalic acid white powder, stir for 10 minutes, and dissolve the solution in water In a hot kettle, heat in an oven at 210°C for 72 hours, and finally wash and dry the obtained vanadium heptoxide nanowires; take 50 mg of the sample and add 40 ml of distilled water, place it under a stirrer with a rotation speed of 600 r / min, and stir for 1 hour. Obtain turquoise vanadium heptoxide ultra-long nanowire dispersion; then, take 40ml of the above-mentioned uniform dispersion, then add 50-200mg of glucose, stir for 10min, mix well, and finally pour the well-mixed above-mentioned solution into a 60ml hydrothermal kettle , raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com