Large-sized built-in ultrasonic alginic acid extractor

An ultrasonic, built-in technology, used in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of low extraction efficiency, long extraction time, poor adaptability, etc., to increase extraction efficiency and improve the effect of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

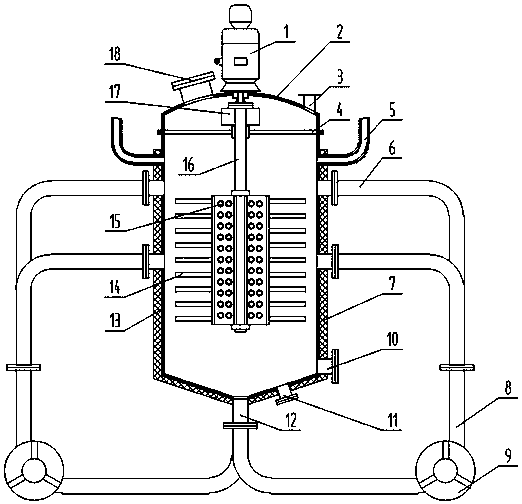

[0024] Embodiment 1: a large-scale built-in ultrasonic alginic acid extractor, comprising an extraction tank 13, characterized in that: a cover 2 is installed above the extraction tank 13, and a discharge port 10 is provided on one side of the bottom of the extraction tank 13, The bottom of extraction tank 13 is provided with circulation liquid inlet 12, and circulation liquid inlet 12 is connected with circulation pump 9 by main pipeline 8, and circulation pump 9 is connected with circulation liquid outlet 6 on the extraction tank 13 by main pipeline 8; The interior of the extraction tank 13 is also provided with a partition 4, the partition 4 is located at the connecting portion of the cover 2 and the extraction tank 13; the cover 2 is also equipped with a stirring drive device 1, and the stirring drive device 1 passes through the flange structure. It is connected with the stirring shaft 16 that passes through the partition 4 and is positioned at the inside of the extraction ...

Embodiment 2

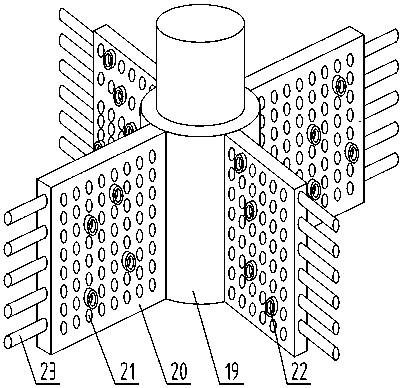

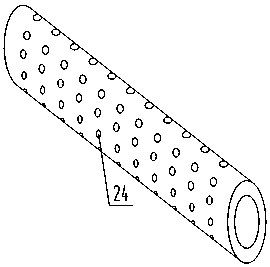

[0025] Embodiment 2: a large-scale built-in ultrasonic alginic acid extractor, wherein the circulating liquid outlet 6 is located in the extraction tank 13 area between the partition plate 4 and the stirring blade 5, and the upper part of the extraction tank 13 is also installed There is overflow pipe 5. The extraction tank 13 is equipped with a slag outlet 11 on one side of the circulating liquid inlet 12 . An observation port 3 and a manhole 18 are installed on the cover body 2 . The stirring blades 15 are four and uniformly distributed around the stirring shaft 16 , wherein a number of uniformly distributed stirring holes 21 are opened on the stirring blades 15 . An annular ultrasonic tool head 22 is installed on the stirring hole 21, and the ultrasonic tool head 22 is connected with an ultrasonic transducer, and the ultrasonic transducer is connected with the ultrasonic generator 17 through an insulating pad wire. The number of ultrasonic tool heads 22 is less than the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com