Preparation method and refining method of ethoxymethylenemalononitrile

A technology of ethoxymethylene malononitrile and a refining method, which is applied in the preparation of carboxylic acid nitrile, the preparation of organic compounds, chemical instruments and methods, etc. Solvent recovery difficulties and other problems, to achieve the effect of solving the inconvenience of solvent recovery, improving the reaction speed and reaction yield, and facilitating solvent recovery and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

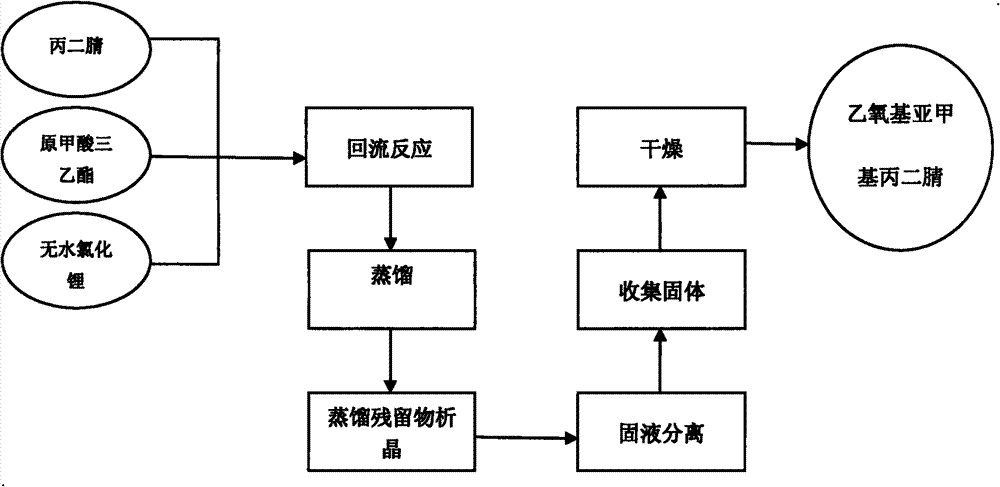

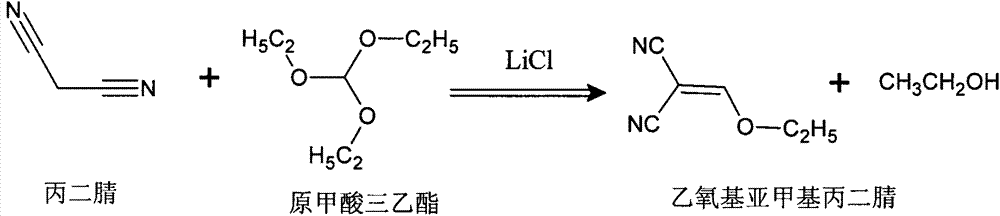

[0024] Example 1 Preparation of ethoxymethylene malononitrile

[0025] In a 1L three-necked reaction flask, add 56g (0.848mol) malononitrile, 150g (1.013mol) triethyl orthoformate and 3g anhydrous lithium chloride, turn on the stirring, heat up to 90℃, reflux and keep for 3h, usually The ethanol produced by the reaction was removed by pressure distillation, the remaining liquid was frozen and crystallized (-5~0℃), filtered with suction, the solid was collected, and dried to obtain 79g of crude ethoxymethylenemalononitrile, with a yield of 76.5% About, the melting point is 64-67℃.

Embodiment 2

[0026] Example 2 Preparation of ethoxymethylene malononitrile

[0027] In a 5L three-necked reaction flask, add 1Kg (15.15mol) malononitrile, 3.2Kg (21.59mol) triethyl orthoformate and 60g anhydrous lithium chloride, stir, heat up to 85℃, reflux and keep for 3h, usually The ethanol produced by the reaction was removed by pressure distillation, the remaining liquid was frozen and crystallized (-5~0℃), solid-liquid separation, the solid was collected, and dried to obtain the crude ethoxymethylene malononitrile dry product 1.35Kg, the yield About 73.2%, the melting point is 65-67°C.

Embodiment 3

[0028] Example 3 Preparation of ethoxymethylene malononitrile

[0029] In a 50L reactor, add 7Kg (105.96mol) of malononitrile, 20Kg (134.95mol) of triethyl orthoformate and 375g of anhydrous LiCl, stir, heat up to 85°C, reflux for 3h, and then distill to remove The ethanol produced by the reaction, the remaining liquid is subjected to freezing crystallization (-5~0℃), solid-liquid separation, solid-liquid separation, solid-liquid separation, solid-liquid collection, and drying to obtain crude ethoxymethylenemalononitrile dry product 10.8Kg, yield 83.5% about. Melting point 64-67°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com