Adjustable building reinforcement rust removing device

A construction steel bar, adjustable technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine parts, etc. The effect of ensuring the rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

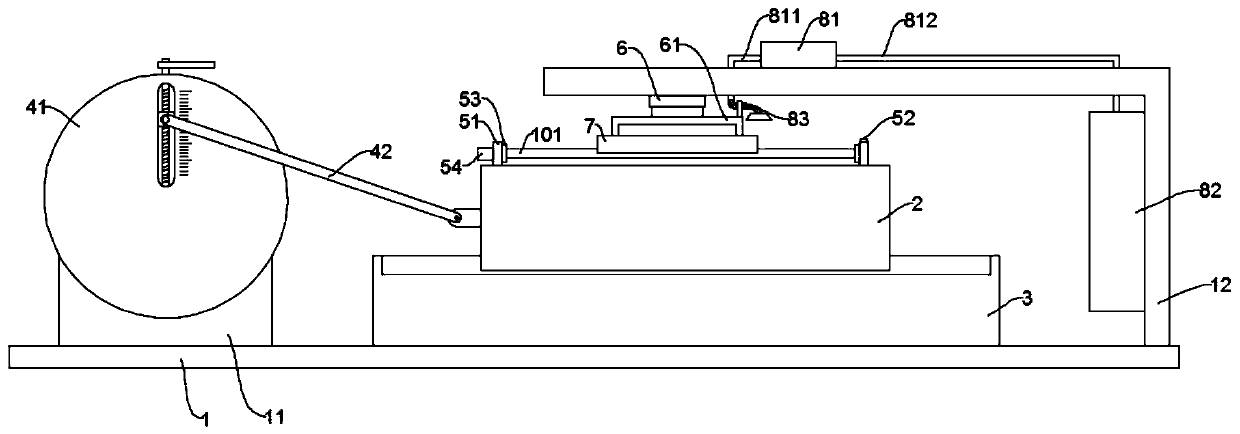

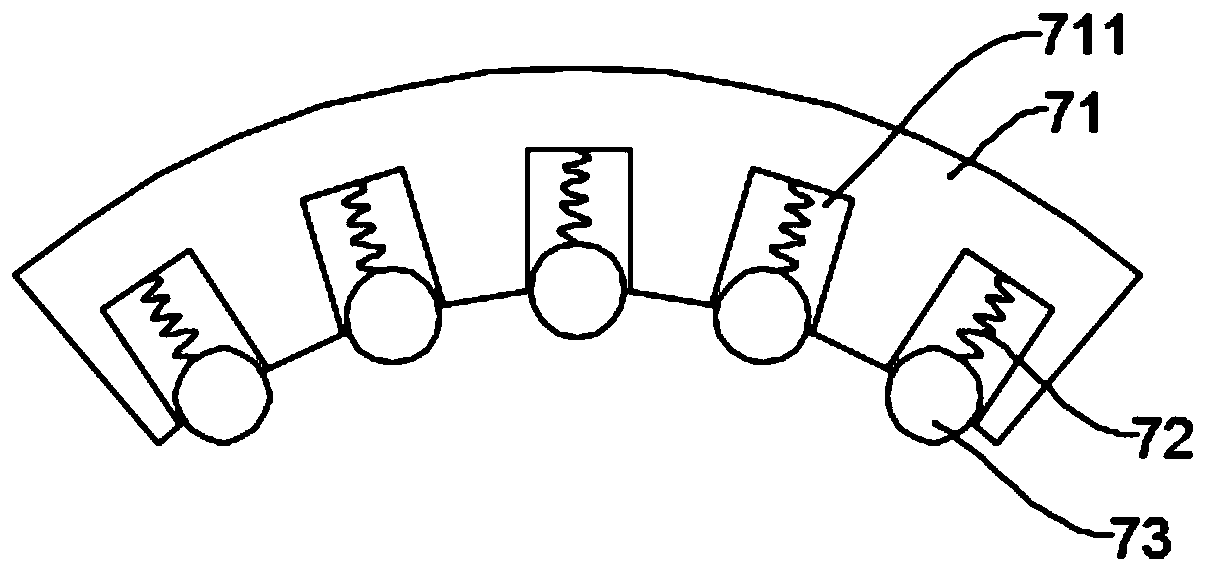

[0022] see Figure 1~4 , in the embodiment of the present invention, a kind of adjustable construction steel bar derusting device comprises base 1, and mounting frame 11, supporting base 3 and supporting frame 12 are fixed on base 1; The top of described supporting base 3 is slidingly connected with working Table 2, a clamping mechanism for fixing the steel bar 101 is arranged on the workbench 2; the lifting device 6 is installed on the position above the workbench 2 on the support frame 12, and the lifting device 6 is connected with the derusting disc 7 through the connecting frame 61 .

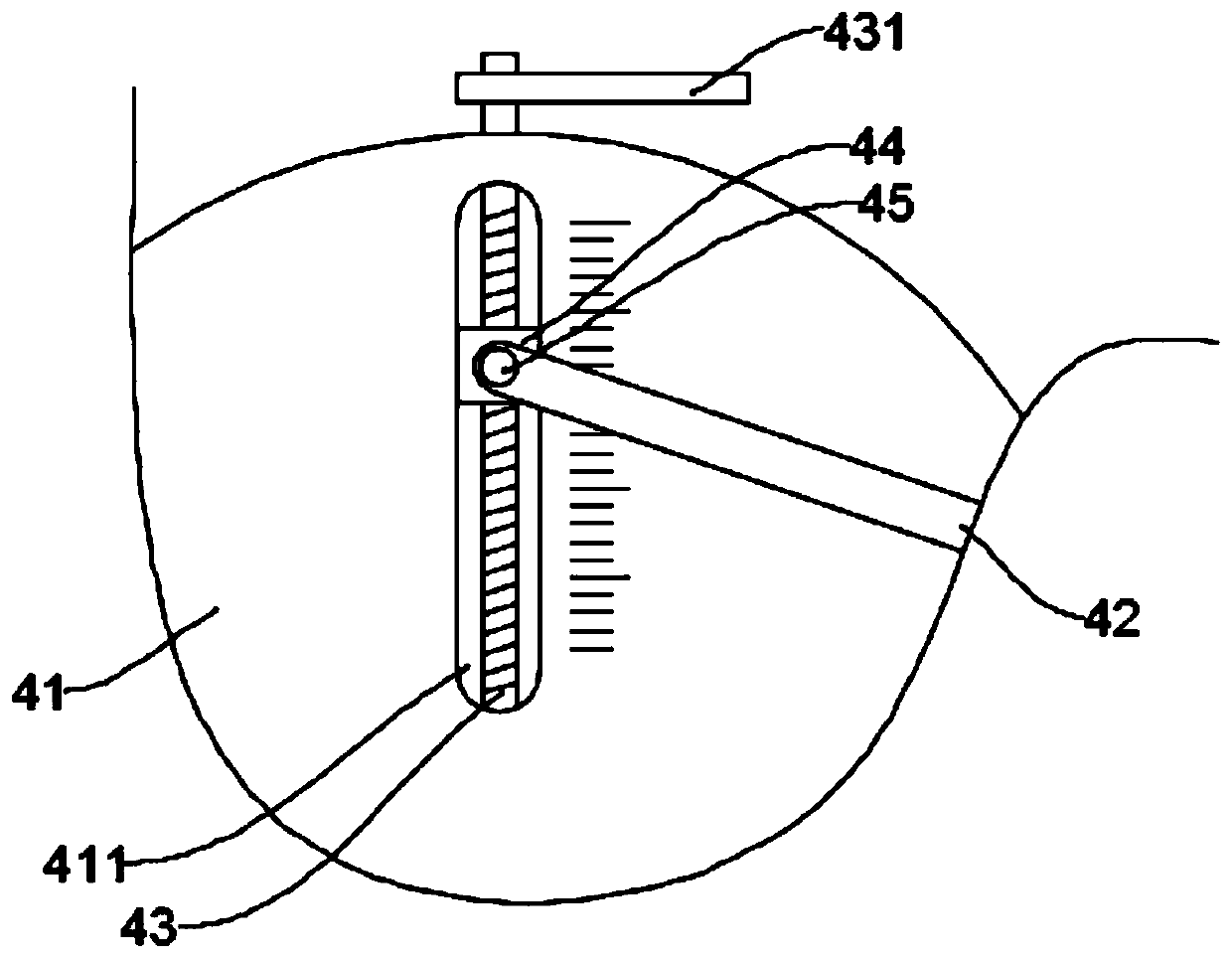

[0023] A driving mechanism for driving the workbench 2 to move is installed on the mounting frame 11; the driving mechanism includes a turntable 41, which is rotatably connected to the mounting frame 11 and driven by a motor (not shown in the figure). There is a chute 411 arranged along the radial direction, and the chute 411 is rotatably connected with a screw rod 43, and the outer periphe...

Embodiment 2

[0034] In this embodiment, an adjustable rust removal device for building steel bars also includes a dust removal mechanism; the dust removal mechanism includes a dust suction fan 81 and a purification box 82; the dust suction fan 81 and the purification box 82 are installed on the support 12, the input end and the output end of the dust suction fan 81 are respectively connected with a suction pipe 811 and an air outlet pipe 812, and the end of the suction pipe 811 extends to the top of the rust removal plate 7 and is connected with a dust suction head 83 for dust suction. The head 83 is fixed on the connecting frame 61; the cleaning liquid is filled in the cleaning box 82, and the end of the air outlet pipe 812 extends below the liquid level of the cleaning box 82; The impurities are sucked into the purification box 82, and the impurities are filtered by the purification liquid, which plays a role in protecting the environment.

[0035] Further, a filter screen 84 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com