Surface rust removing device and method of rolled steel

A technology of steel and filter devices, which is applied to steel surface derusting devices and the field of steel surface derusting, which can solve problems such as inconvenient use, turbid water, and affecting the effect of sand blasting and derusting, and achieve the effect of convenient use and guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

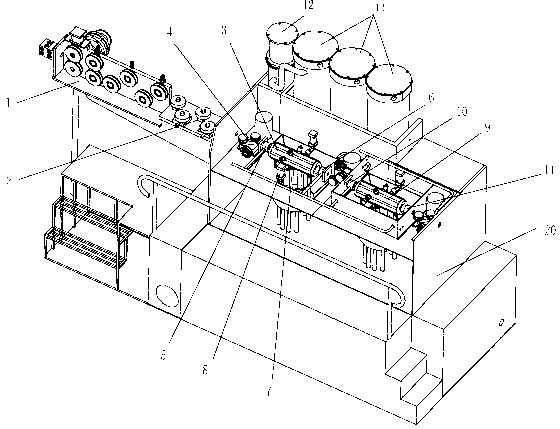

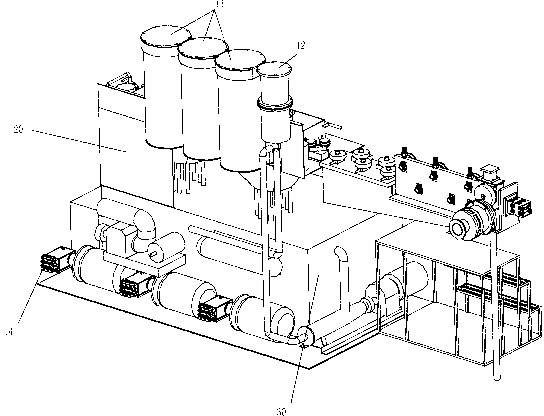

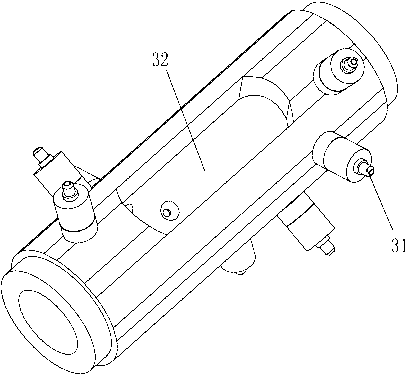

[0034] Such as figure 1 , figure 2 As shown, the surface derusting device for steel of the present invention includes a guide part, a primary sandblasting part, a secondary sandblasting part, and a filter device; the primary sandblasting part and the secondary sandblasting part are arranged in the sand box 20; the sand box 20 A guide portion is set at the entrance of the sand box 20; a filtering device is set on one side of the sand box 20;

[0035] The guide part includes a longitudinal straightening guide wheel set 1 and a horizontal straightening guide wheel set 2; the longitudinal straightening guide wheel set 1 includes a plurality of vertically arranged guide wheels, and the vertical guide wheels are divided into upper and lower rows; The guide wheel set 2 includes a plurality of guide wheels set horizontally, and the horizontal guide wheels are divided into left and right rows; the workpiece to be processed enters from the entrance of the guide part, and the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com