A Reverse Deformation Correction Process of Narrow Section H Steel

A technology of anti-deformation and cross-section, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of low efficiency, high production cost, time-consuming and labor-intensive, etc., to reduce labor intensity, ensure production and delivery The effect of reducing the demand for goods and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

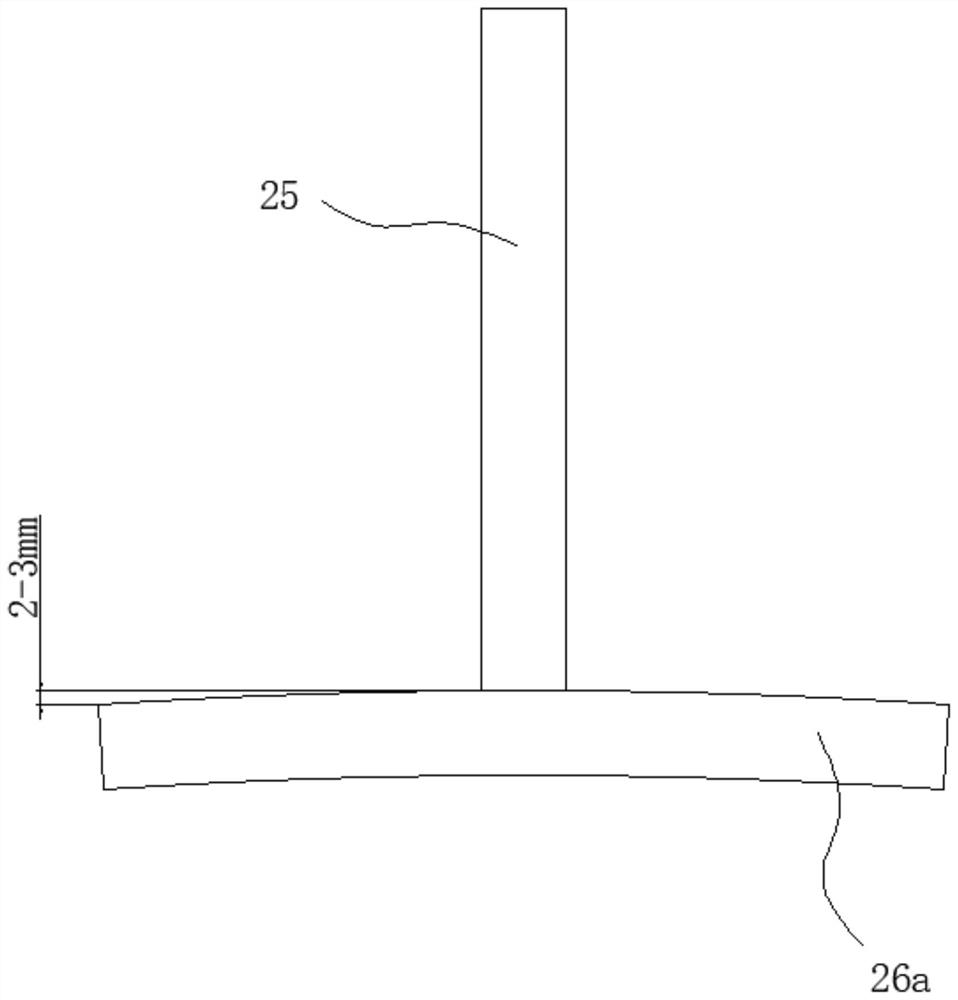

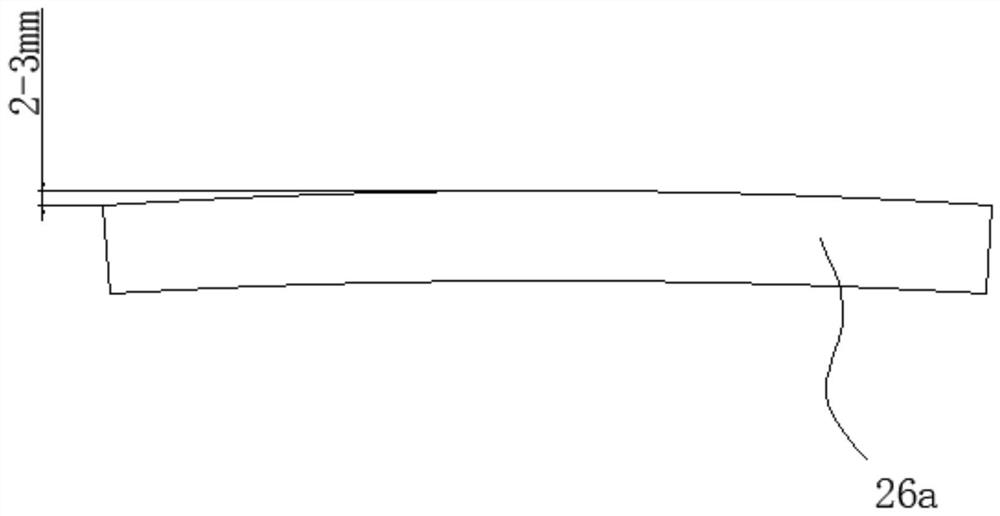

[0044] In the anti-deformation correction process of the narrow-section H-steel in this embodiment, the narrow-section H-steel can be defined as an H-shaped steel with a section ≤ H300*300. The anti-deformation correction process of narrow-section H steel can use the principle of thermal expansion and contraction at the weld position, so that the pre-made anti-deformation at the flange plate can be naturally corrected and recovered, and one positive and one negative will be naturally offset to realize the narrow section H. Calibration process of section steel.

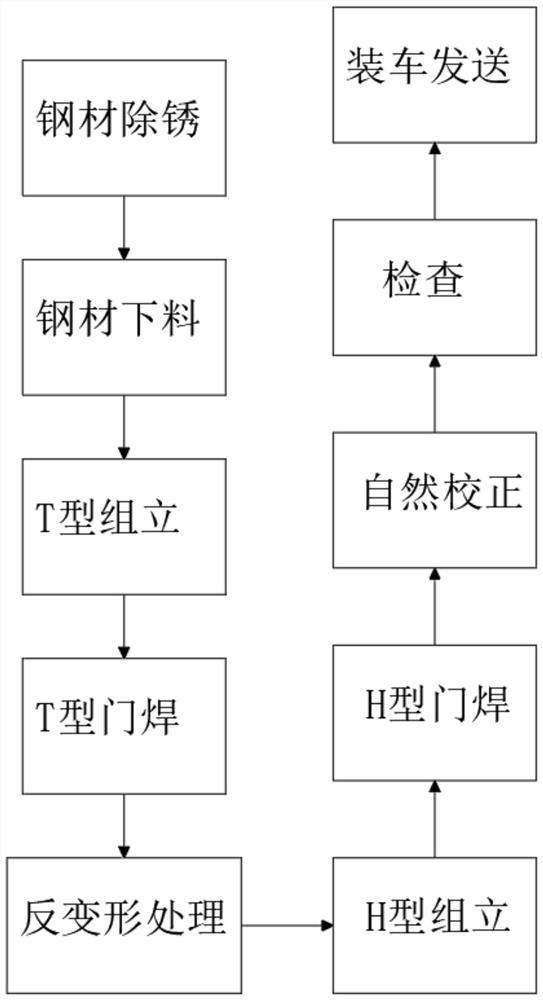

[0045] Please combine Figures 1 to 7 , the anti-deformation correction process of narrow section H steel includes the following steps:

[0046] 1) Steel rust removal: According to the corrosion, pitting or scratch defects on the steel surface, when the depth is less than or equal to 1 / 2 of the negative deviation value of the steel thickness, the steel is directly used; when the depth is greater than the thickness of ...

Embodiment 2

[0059] Please combine Figure 8 to Figure 10 , this embodiment 2 provides a rust removal equipment, which is used for derusting treatment in step 1) of the anti-deformation correction process of the above-mentioned narrow-section H steel. The derusting equipment includes a shell 1, which is separated by a vertical partition 2 to form a cavity 1 (not marked) and a cavity 2 (not marked), and the cavity 1 is used to fix the steel to be derusted (not marked) bearing frame 3. A derusting mechanism is provided above the carrier frame 3 . The surface of the steel to be derusted fixed on the carrier 3 can be derusted by the derusting mechanism. In this embodiment, a door (not shown) for closing the first cavity is installed on the outer side of the housing 1 .

[0060] The derusting mechanism includes a raceway-shaped ring body 8, and both ends of the raceway-shaped ring body 8 are fixed with limit rods 11, and the other ends of the two limit rods 11 are connected to the correspond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com