Steel pipe sand blasting rust removing device

A technology for sand blasting and rust removal and steel pipe, which is applied to used abrasive treatment devices, abrasive jet machine tools, abrasives, etc., can solve the problems of mirror pollution, bad mirror and safety problems, affecting the quality of steel pipe 100 rust removal, etc. , to reduce pollution and ensure the effect of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

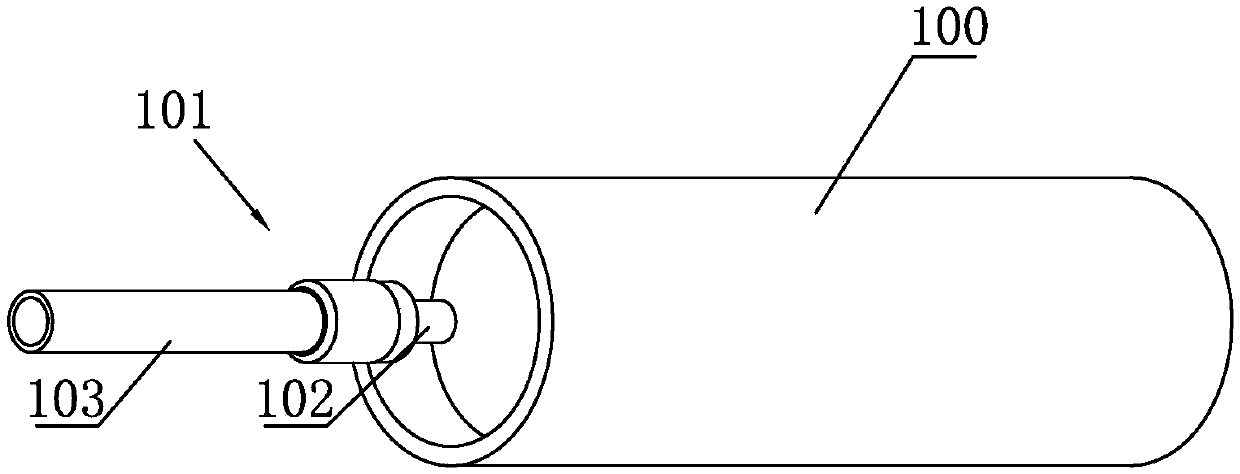

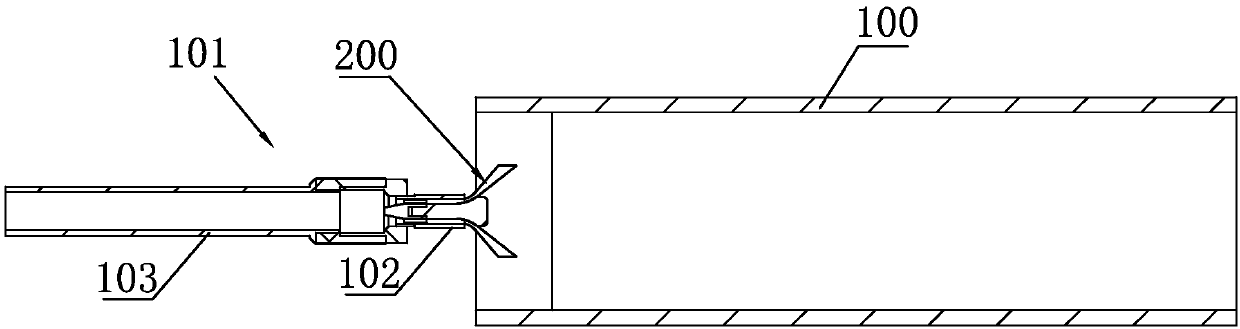

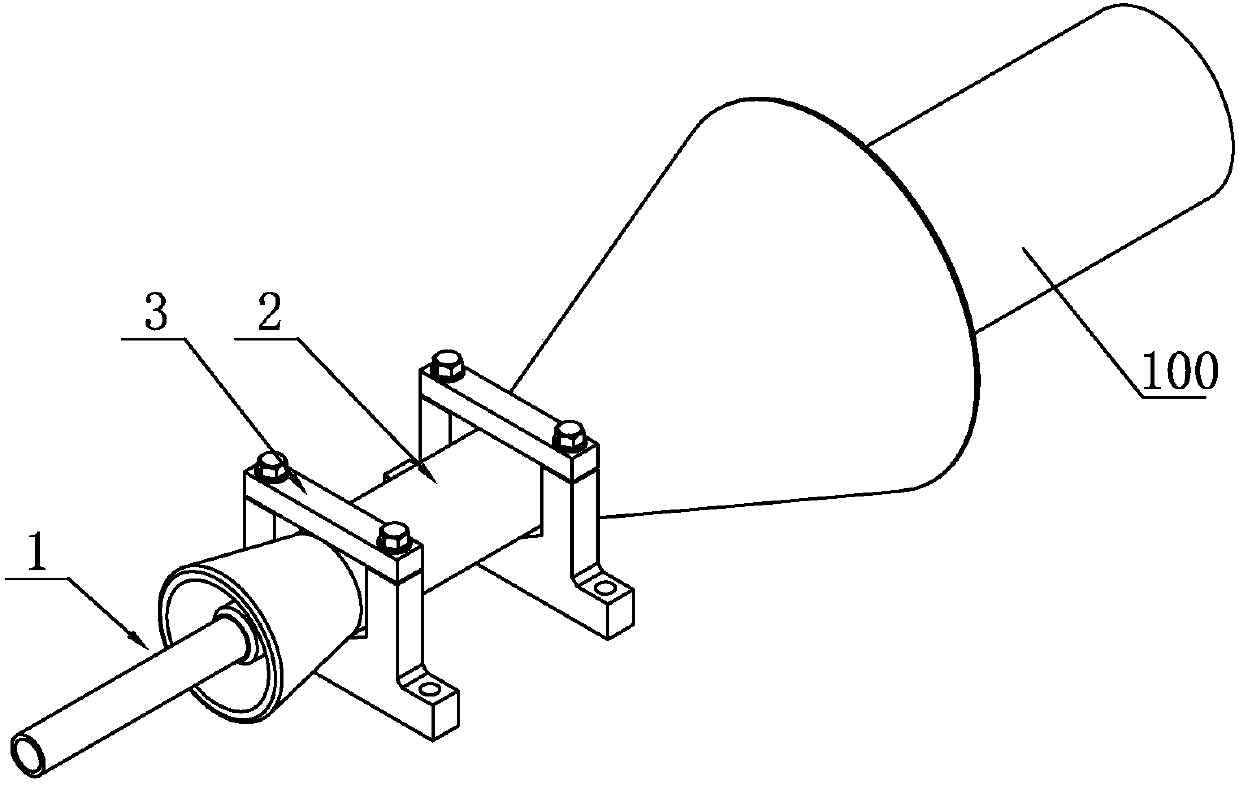

[0024] Such as Figure 2 to Figure 7 As shown, a steel pipe blasting and derusting device according to the present invention is used for blasting and derusting the inner wall of the steel pipe 100 . The steel pipe sandblasting derusting device includes a sandblasting gun 1 and a sandblasting positioning assembly.

[0025] The sandblasting gun 1 has a sandblasting gun nozzle 11 for scattering sand shot 200 outward and a sandblasting pipe 12 for delivering sand shot 200 to the sandblasting gun nozzle 11 . The sandblasting pipe 12 is connected with the sandblasting gun nozzle 11 . The sandblasting gun nozzle 11 can spray the shot sand 200 outwards at a certain speed in the form of scattering.

[0026] The blasting positioning assembly includes a positioning tube 2 and a fixing seat 3 for installing and fixing the positioning tube 2 . The two ends of the positioning pipe 2 are respectively a first end 21 for covering the sandblasting gun nozzle 11 and a second end 22 for coveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com