Mechanical derusting equipment for wire rods

A technology for mechanical rust removal and wire rod application in metal processing equipment, grinding/polishing equipment, grinding racks, etc., which can solve the problems of poor rust removal effect and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are given in conjunction with the embodiments.

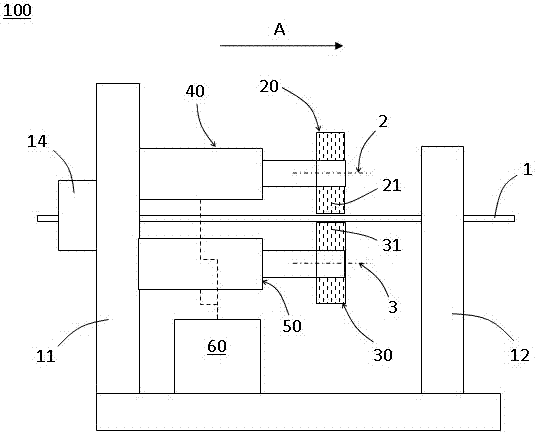

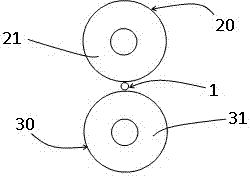

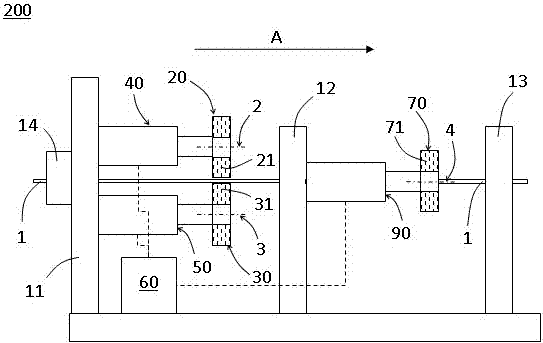

[0020] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of a wire rod mechanical descaling device 100 according to an embodiment of the present invention, figure 2 It is a schematic diagram of the distribution of the first turntable 20 and the second turntable 30 according to an embodiment of the present invention.

[0021] The wire rod mechanical descaling device 100 includes a bracket, a first turntable 20 , a second turntable 30 , a first transmission part 40 , a second transmission part 50 and a driving part 60 .

[0022] The bracket includes a first boss 11 and a second boss 12 , and the first boss 11 and the second boss 12 respectively have wire-passing holes for passing the wire 1 to be derusted along the routing direction A. In one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com