Crack-resistant gypsum board

A technology of gypsum board and substrate, which is applied in the field of building decoration materials, can solve the problems of shedding, poor crack resistance, and damage to building decoration, etc., and achieve the effects of reducing the bending range, enhancing crack resistance, and enhancing local strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

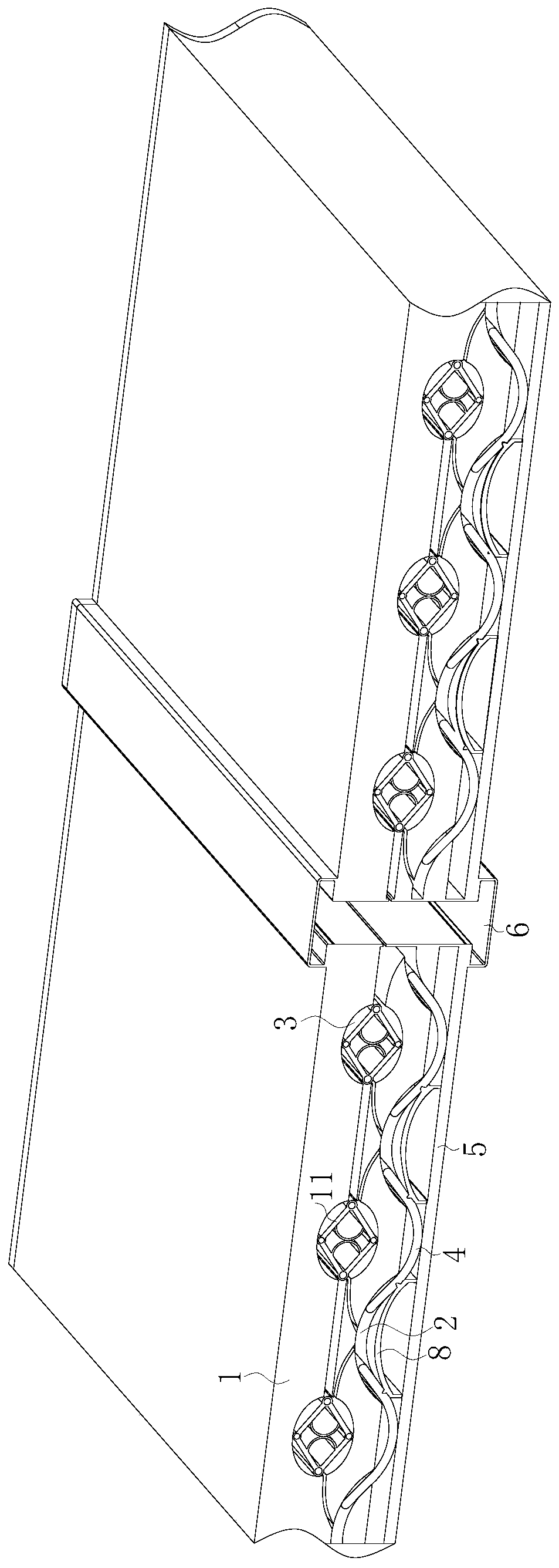

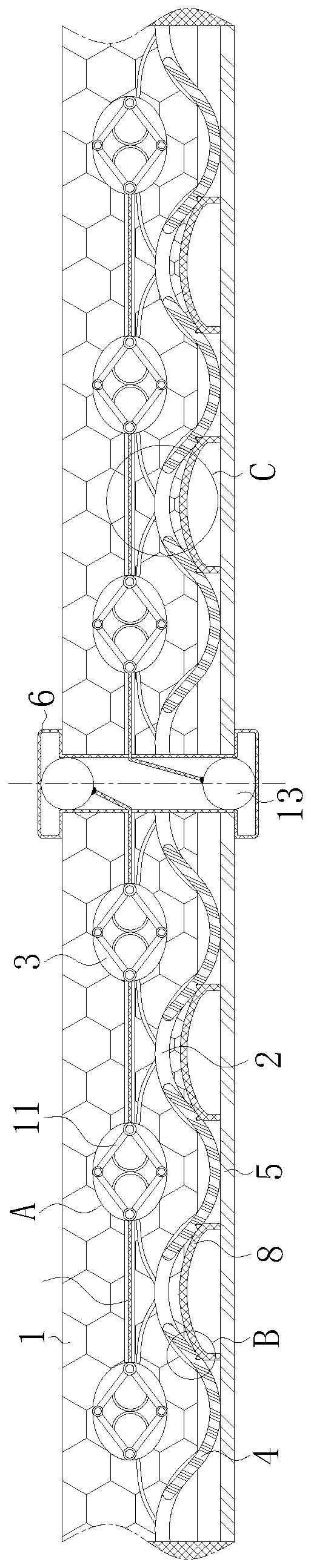

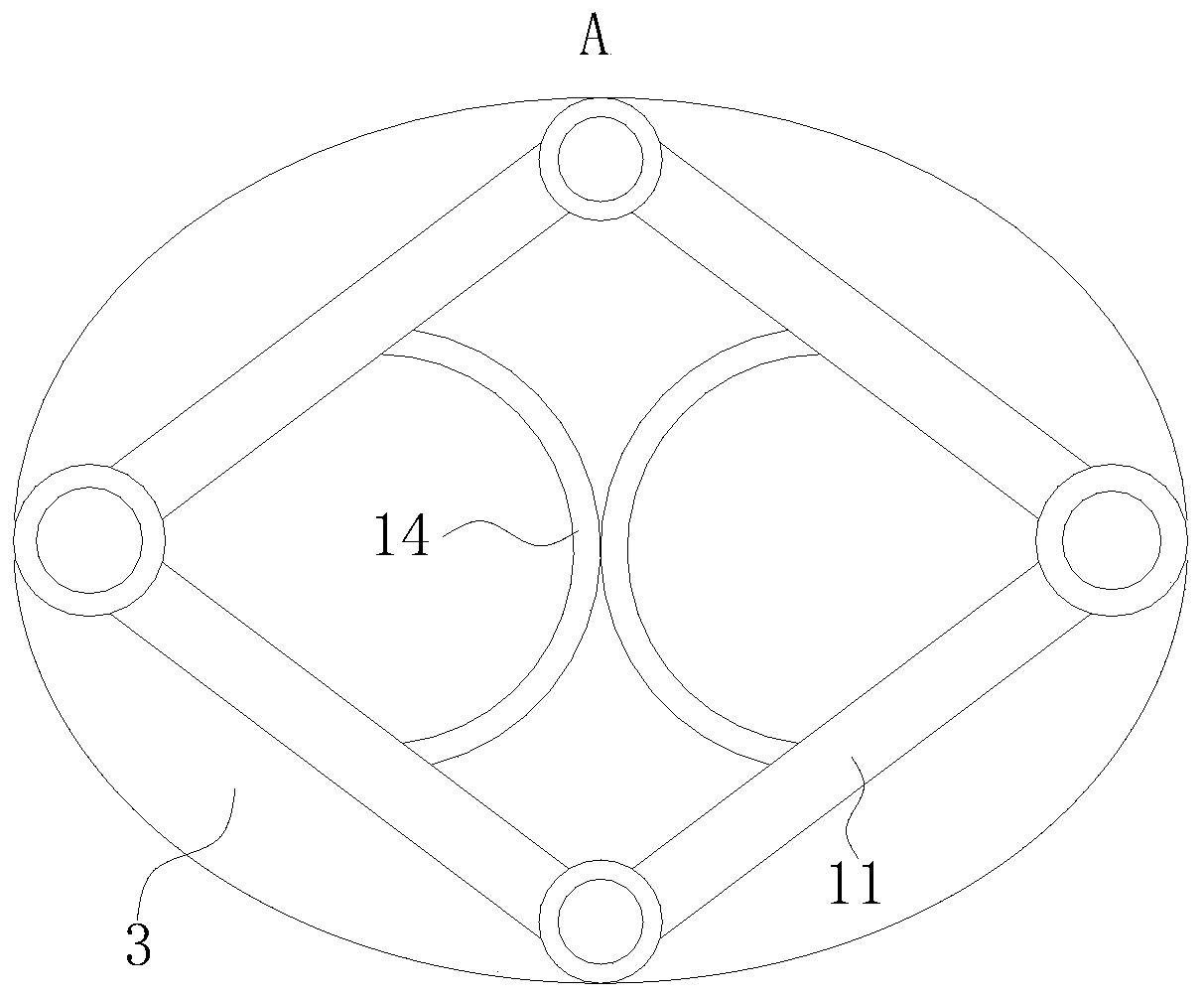

[0022] Such as Figure 1 to Figure 5 As shown, a crack-resistant gypsum board according to the present invention includes a base plate 1, and the outer side of the base plate 1 is provided with evenly distributed arc-shaped grooves 2, and the inside of the base plate 1 is provided with uniformly distributed cavities 3; Arc-shaped plates 4 corresponding to the arc-shaped slots 2 are inserted between adjacent arc-shaped slots 2 ; the arc-shaped plates 4 are used to strengthen the strength of the substrate 1 . When working, gypsum board has been widely used in various buildings such as residences, office buildings, shops, hotels and industrial plants for interior partition walls, wall cladding panels (replacing plastering layers on walls), ceilings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com