High-ductility maraging steel with excellent fatigue resistance and preparation method thereof

A maraging steel, anti-fatigue technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as microscopic yield-induced cracks, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The method for preparing a high ductility maraging steel with excellent fatigue resistance according to an embodiment of the present invention includes the following steps:

[0032] a. Melting maraging steel raw materials into molten steel under vacuum and pouring into ingots;

[0033] b. The ingot in the step a is subjected to tissue homogenization treatment, forged into a slab, and air-cooled to room temperature;

[0034] Then carry out tissue homogenization treatment, and then carry out hot rolling treatment, and air-cool the obtained plate to room temperature;

[0035] c. Homogenizing the microstructure of the plate obtained in step b, followed by quenching, annealing, and re-quenching to obtain a high-ductility maraging steel.

[0036] According to the advantages and technical effects brought by the preparation method of high-ductility maraging steel with excellent fatigue resistance according to the embodiment of the present invention, 1. The method of the embodi...

Embodiment 1

[0046] The raw material of maraging steel is smelted in a vacuum induction furnace with a furnace temperature of 1520°C and cast into an ingot. The ingot structure was homogenized, heated to 1150°C, treated at a constant temperature for 2.5 hours, then forged into a slab with a thickness of 75mm, and then air-cooled to room temperature. Homogenize the structure of the slab again, heat it to 1200°C, hold a constant temperature treatment for 3 hours, and then carry out hot rolling treatment, in which the starting rolling temperature is 1150°C, the final rolling temperature is 900°C, and the pass is 5 times to obtain a plate thickness of 15mm The plate was cooled to room temperature by air cooling. The rolled structure is homogenized, heated to 1000°C, treated at a constant temperature for 1.5h, quenched in brine, and then annealed. The annealing temperature is 500°C, and the annealing time is 3h. Body aged steel.

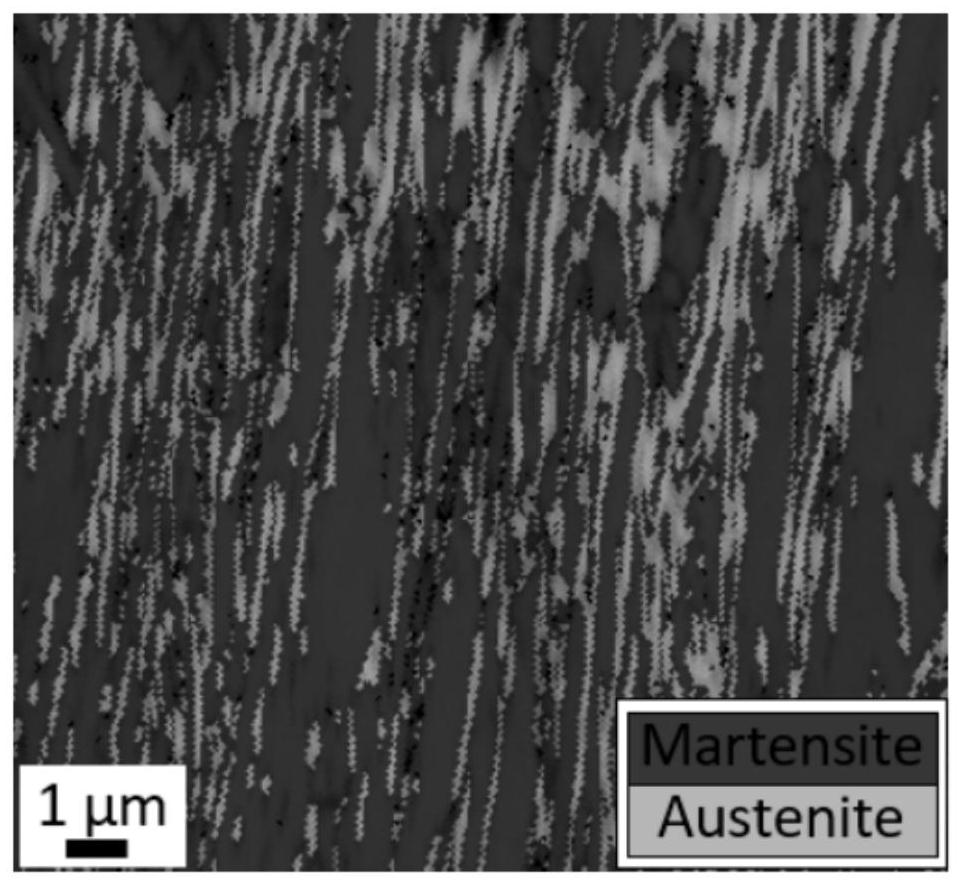

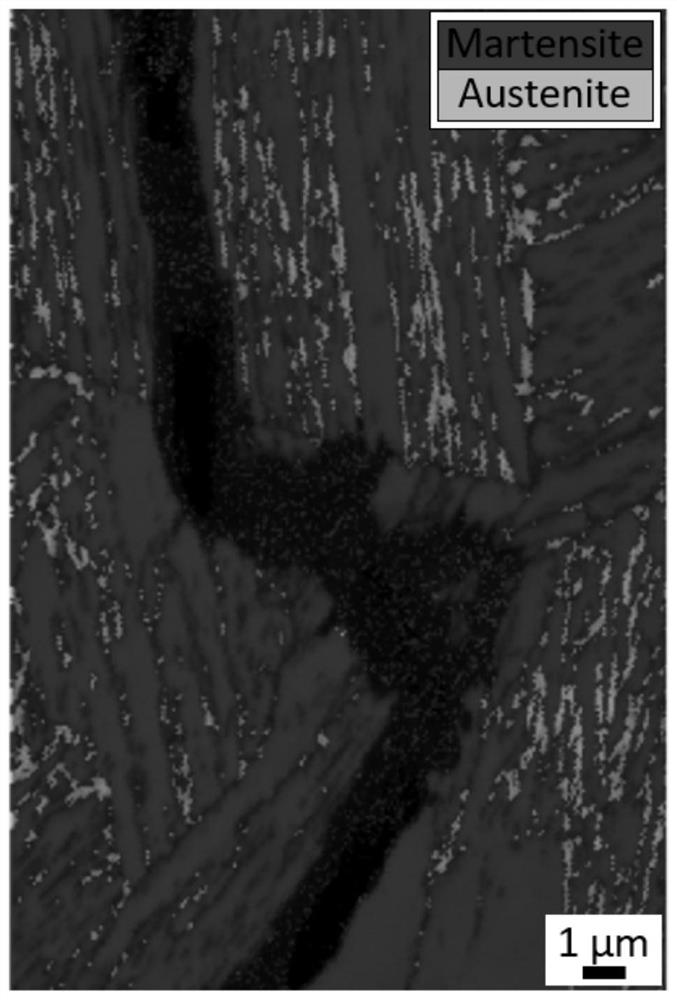

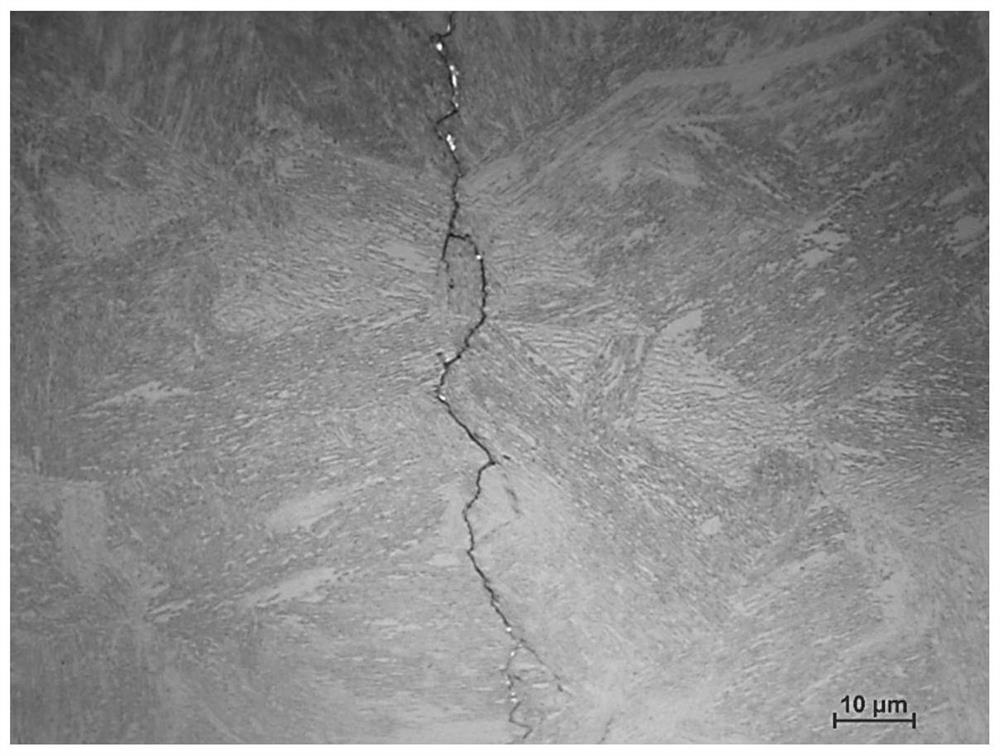

[0047] Such as figure 1 As shown, the morphology of retained ...

Embodiment 2

[0052] The maraging steel raw material is smelted in a vacuum induction furnace with a furnace temperature of 1500°C and cast into an ingot. The ingot structure was homogenized, heated to 900°C, treated at a constant temperature for 4 hours, then forged into a slab with a thickness of 60mm, and then air-cooled to room temperature. Homogenize the structure of the slab again, heat it to 1050°C, and treat it at a constant temperature for 3.5 hours, and then perform hot rolling treatment, wherein the starting rolling temperature is 1150°C, the final rolling temperature is 900°C, and the pass is 4 times, and the plate thickness is obtained. 25mm plate, cooled to room temperature by air cooling. The rolled structure is homogenized, heated to 910°C, treated at a constant temperature for 2 hours, quenched in normal temperature water, and then annealed. The annealing temperature is 400°C, and the annealing time is 8 hours. Tempered aging steel.

[0053] In the performance test, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com