Fully-enclosed device of upper part of injecting layer for downhole operation of high-pressure water injection well

A technology for water injection wells and injection layers, which is used in wellbore/well valve devices, wellbore/well components, sealing/packing, etc., which can solve the problem of expensive equipment, the influence of the uniform propulsion effect of water injection wells, and high operating costs. problems, to achieve the effect of simple construction, significant profits and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

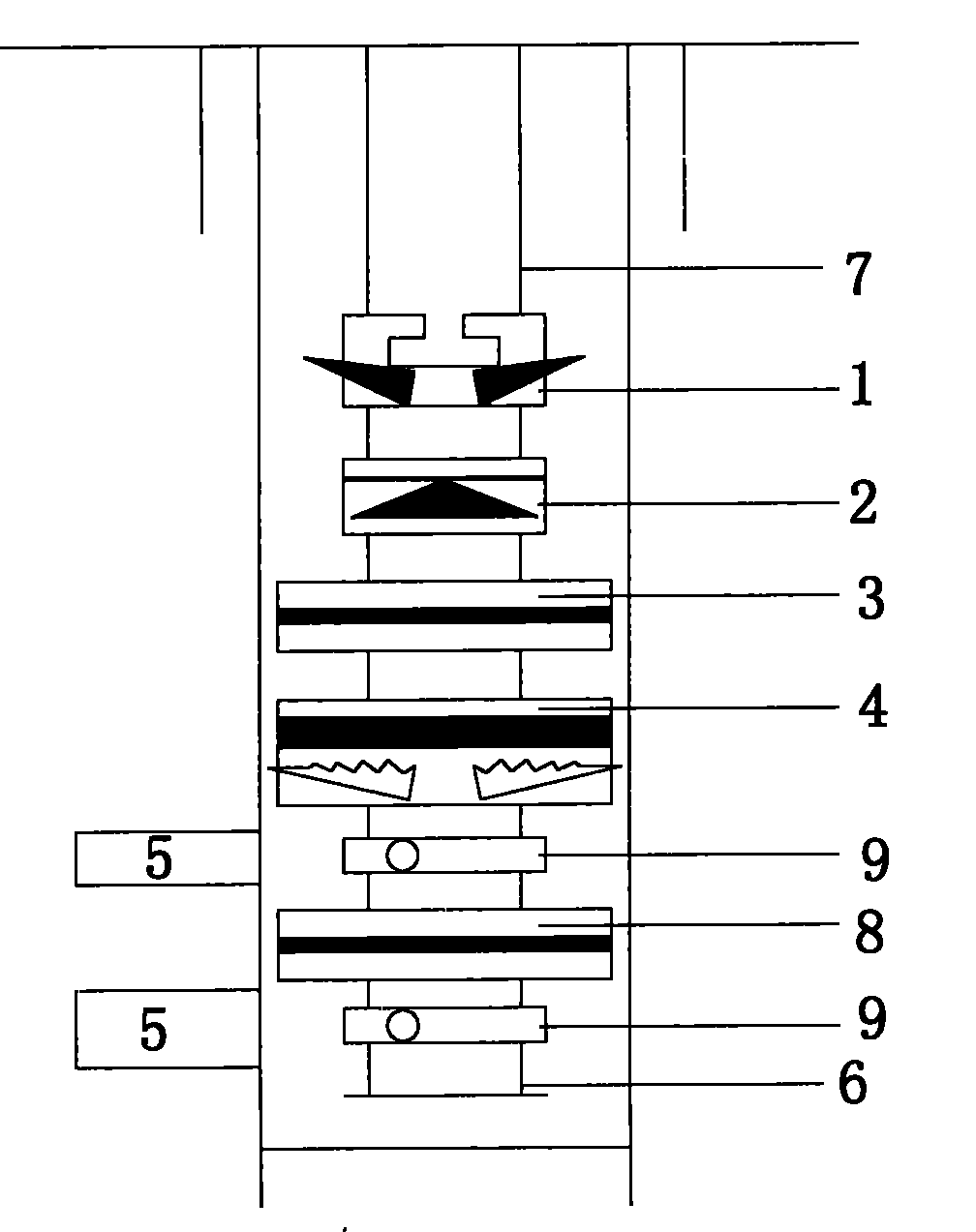

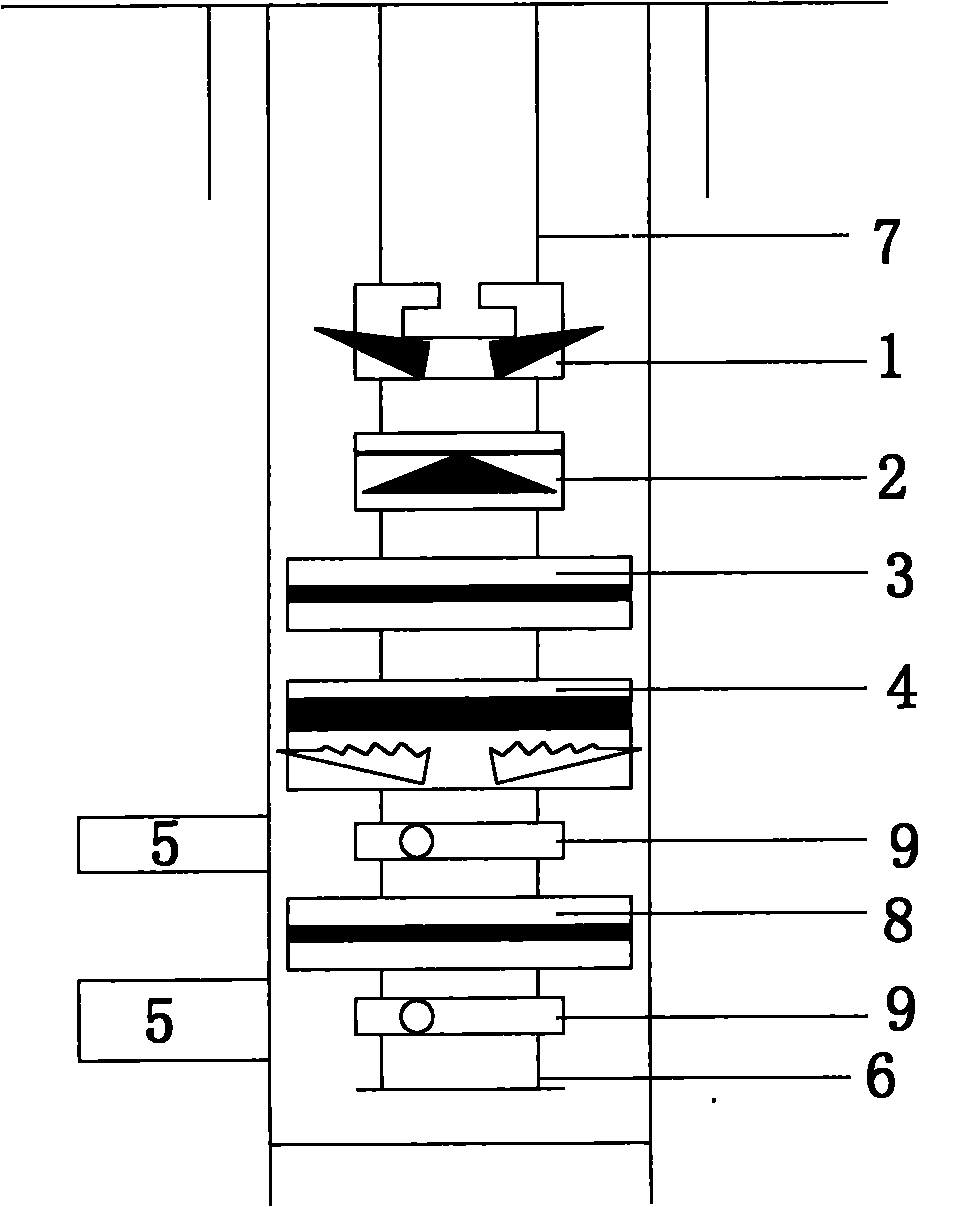

[0011] As shown in the figure, the upper part of the injection layer for downhole operation of high-pressure water injection wells is fully enclosed, which includes a hand 1 connected to the threaded thread of the tubing, an automatic sealing mechanism 2 matched with the inner wall of the tubing, and an automatic sealing and anchoring mechanism 3 for the oil casing annulus , 4 and tail water injection mechanism; the oil casing annular automatic sealing anchor mechanism 3, 4 is set by rotating the pipe string and the wellhead to apply working setting pressure to seal the oil casing annular space; the tubing automatic sealing mechanism 2 adopts The one-way valve structure ensures that the high-pressure water in the oil layer cannot escape from the oil pipe; the packer of the tail water injection mechanism is set to ensure layered injection.

[0012] The oil casing annulus automatic sealing and anchoring mechanisms 3 and 4 of the present invention can choose Y111 packer and Y221 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com