Well repair method for treating coalbed methane well sand burial

A technology for coalbed methane wells and workover, which is applied in wellbore/well components, drilling equipment, earthwork drilling and mining, etc. It can solve problems such as consuming large financial resources, manpower, damage to coal reservoirs, and damage to coal reservoir fracture systems. The effect of reducing production costs, saving workover costs, and reducing workover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

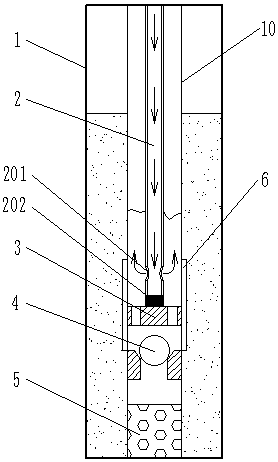

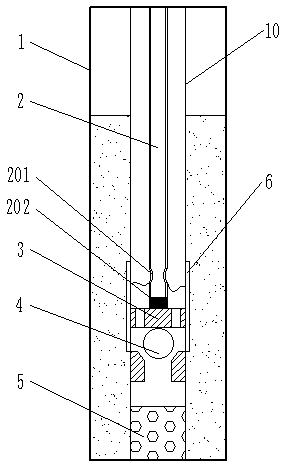

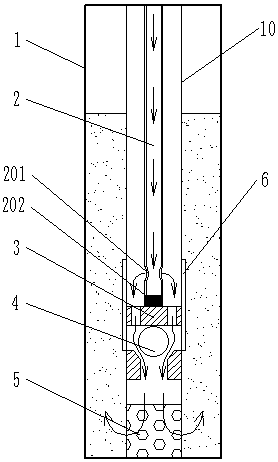

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] A workover method for dealing with sand buried coalbed gas wells, specifically comprising the following steps:

[0024] 1) Transport the workover locomotive to the coalbed methane workover site, erect the workover derrick, set up the oil pipe bridge (for placing oil pipes and sucker rods), and dismantle the instruments.

[0025] 2) Remove the polished rod sealing box 9 (to seal the space between the polished rod and the oil pipe), and lift the sucker rod and pump barrel plunger in the oil pipe 10.

[0026] 3) Disassemble the wellhead flange (to disconnect the tubing 10 from the wellbore), and when the tubing string is lifted, it is found that it cannot be lifted; prepare the air compressor 7, the hollow sucker rod 2, and the high-pressure rubber hose 11.

[0027] 4) if figure 1 As shown, a hollow sucker rod 2 equipped with a strong magnet 202 at the tail end and havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com