Mechanical thermal cleaning method for pipe poles in oilfield wellhead sites

A technology for thermal cleaning and pipe rods, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well components, etc. It can solve the problems of environmental pollution at the wellhead site, low heat energy utilization rate, shortening workover time, etc., and achieve shortening workover Time, convenient transportation, and the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

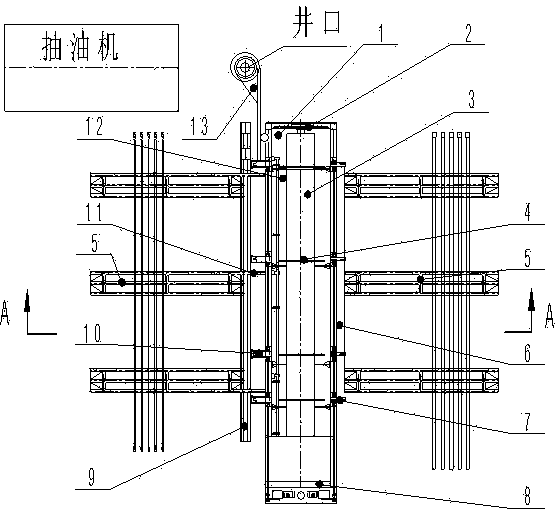

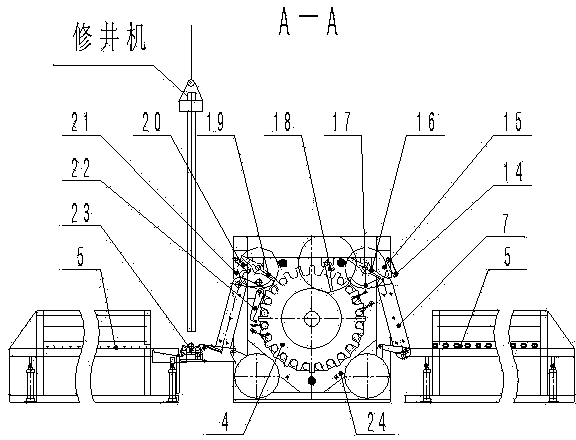

[0045] The invention relates to a mechanical heat cleaning method for pipe rods at the wellhead site of an oil field.

[0046] combine Figure 1-2 , the pipe and rod described in the mechanical heat cleaning method of the present invention refers to the oil pipe and the sucker rod, and the machinery described in the mechanical heat cleaning method includes a pipe and rod thermal cleaning device 1 and auxiliary equipment, wherein the pipe and rod thermal cleaning device 1 refers to The Chinese patent "An automatic high-efficiency oil pipe thermal cleaning device" has been partially modified and installed. To clean the sucker rod, secondly, the side entry and side exit of the pipe rod is realized. Auxiliary equipment is equipped around the pipe rod thermal cleaning device 1.

[0047] The conveying material rack 5 is composed of a material rack and a transition bridge 11. The material rack is welded by petroleum pipes. The conveying material rack 5 can be equipped with pipe stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com