Gantry derrick allowing operation under pressure

A pressurized operation and gantry-type technology, which is applied to drilling equipment, earthwork drilling, support devices, etc., can solve the problems of high resource consumption such as manpower and material resources, no lifting capacity, and low work efficiency, so as to reduce manpower and material resources consumption, shorten workover time, and improve workover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

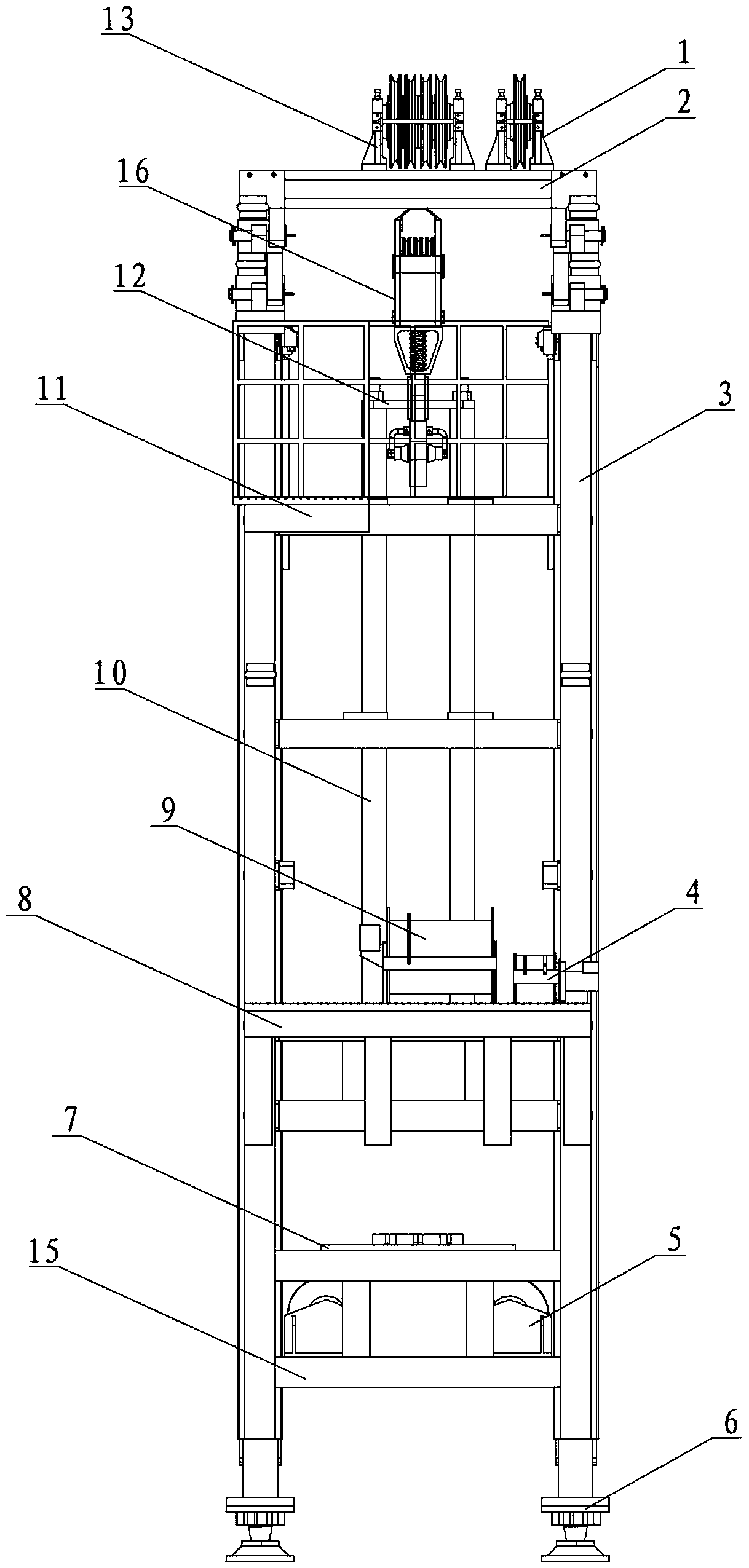

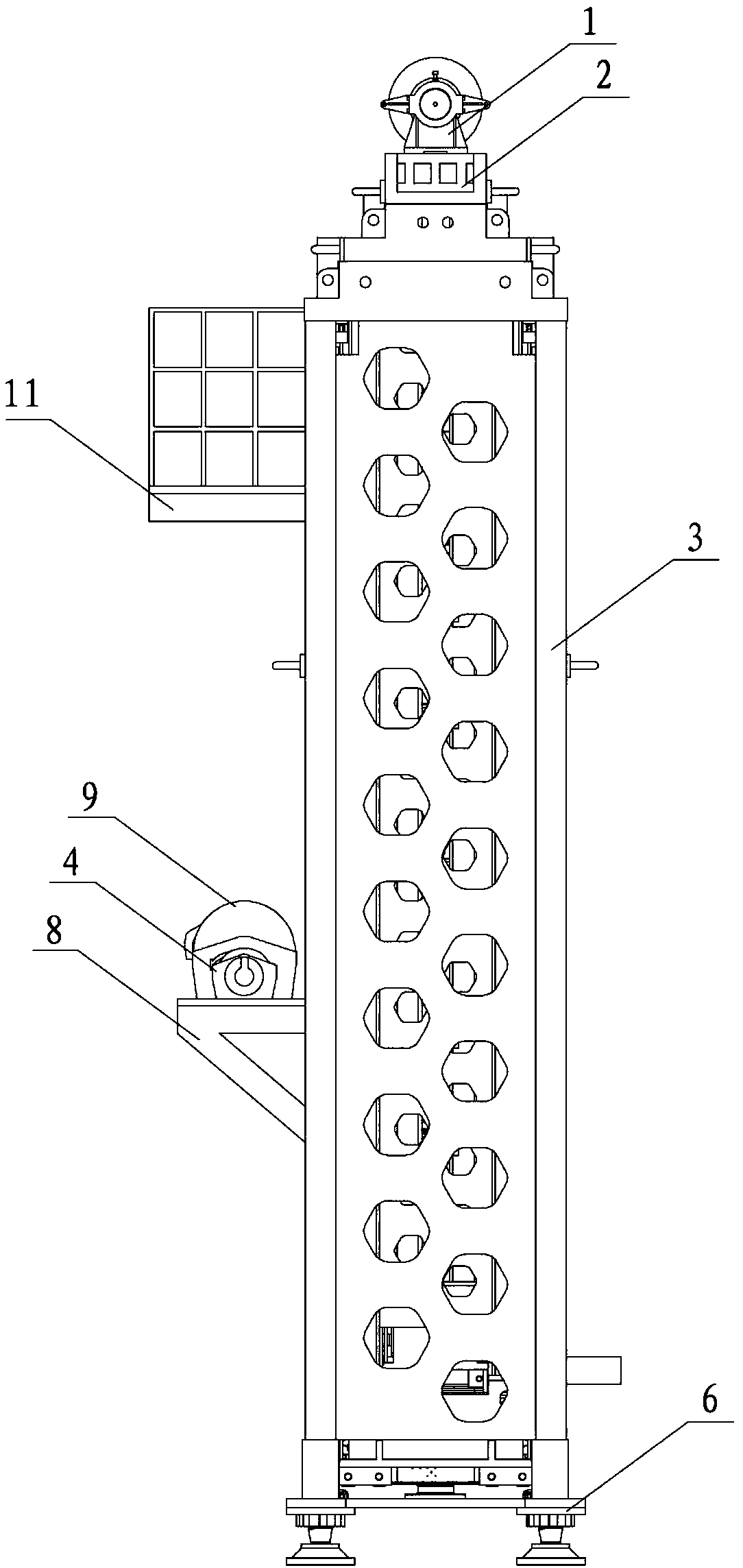

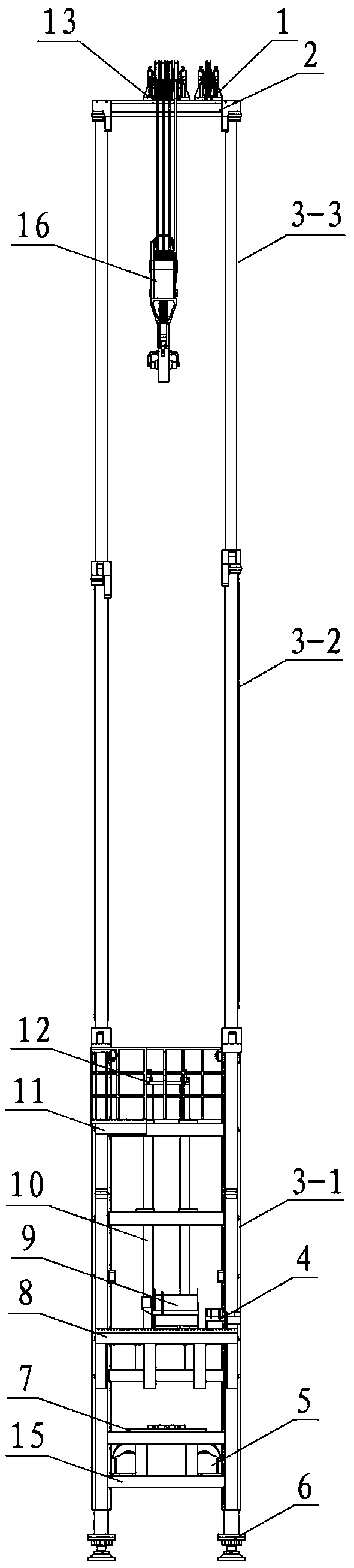

[0029] see figure 1 , figure 2 , the present invention includes two gantry masts 3, a mast beam 2, a large fixed pulley block 13, a small fixed pulley block 1, four lifting hydraulic cylinders 10, a swimming hook 16, a lifting platform 12, an operating platform 11, and a supporting platform 8 , load-bearing platform 7, large hook hydraulic winch 9, auxiliary hook hydraulic winch 4, four hydraulic legs 6 and connecting seat 15. The mast is not directly installed on the ground. There are two hydraulic outriggers on each piece of mast, and two pieces of mast have four hydraulic outriggers. These four hydraulic outriggers are placed directly on the ground to form a stable structure. If the ground is soft, a larger pad can be placed under the hydraulic outrigger.

[0030] The two ends of the mast beam 2 are respectively connected to the upper parts of the two gantry masts 3 through bolt assemblies to form a gantry type. The maximum bearing capacity of the mast beam 2 can reach 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com