Patents

Literature

47results about How to "Improve workover efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

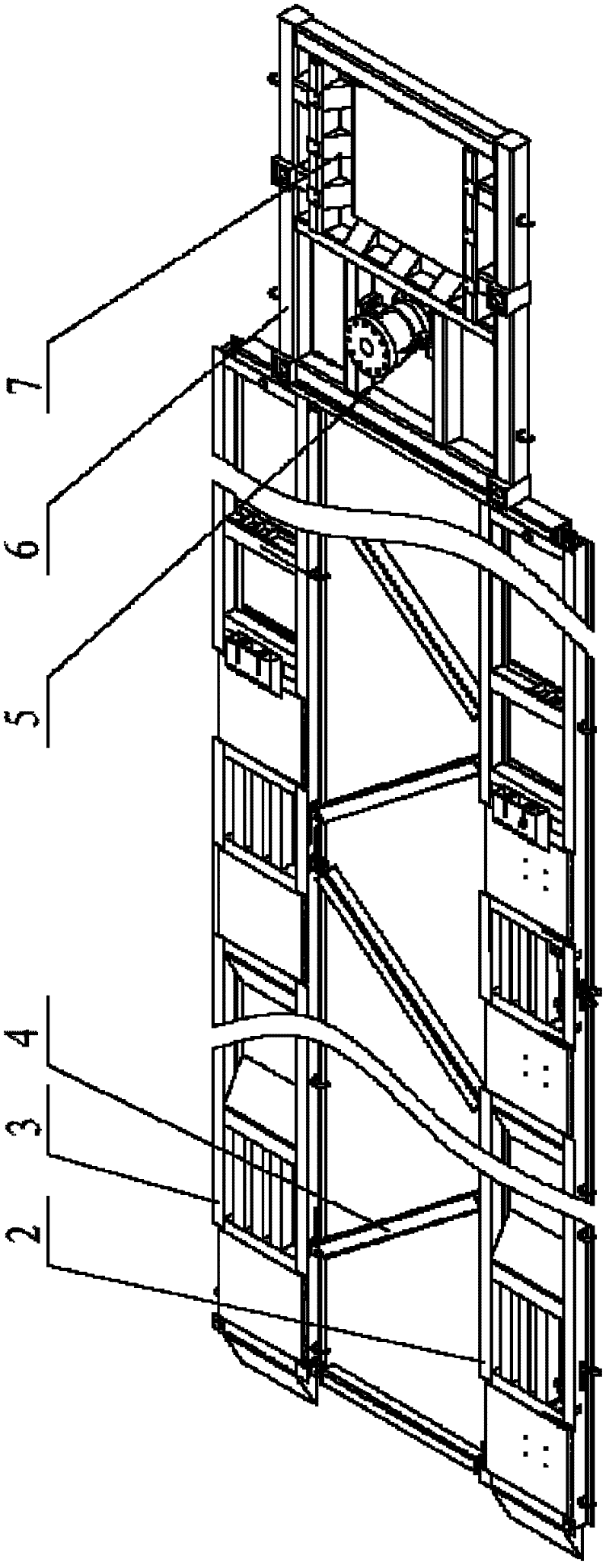

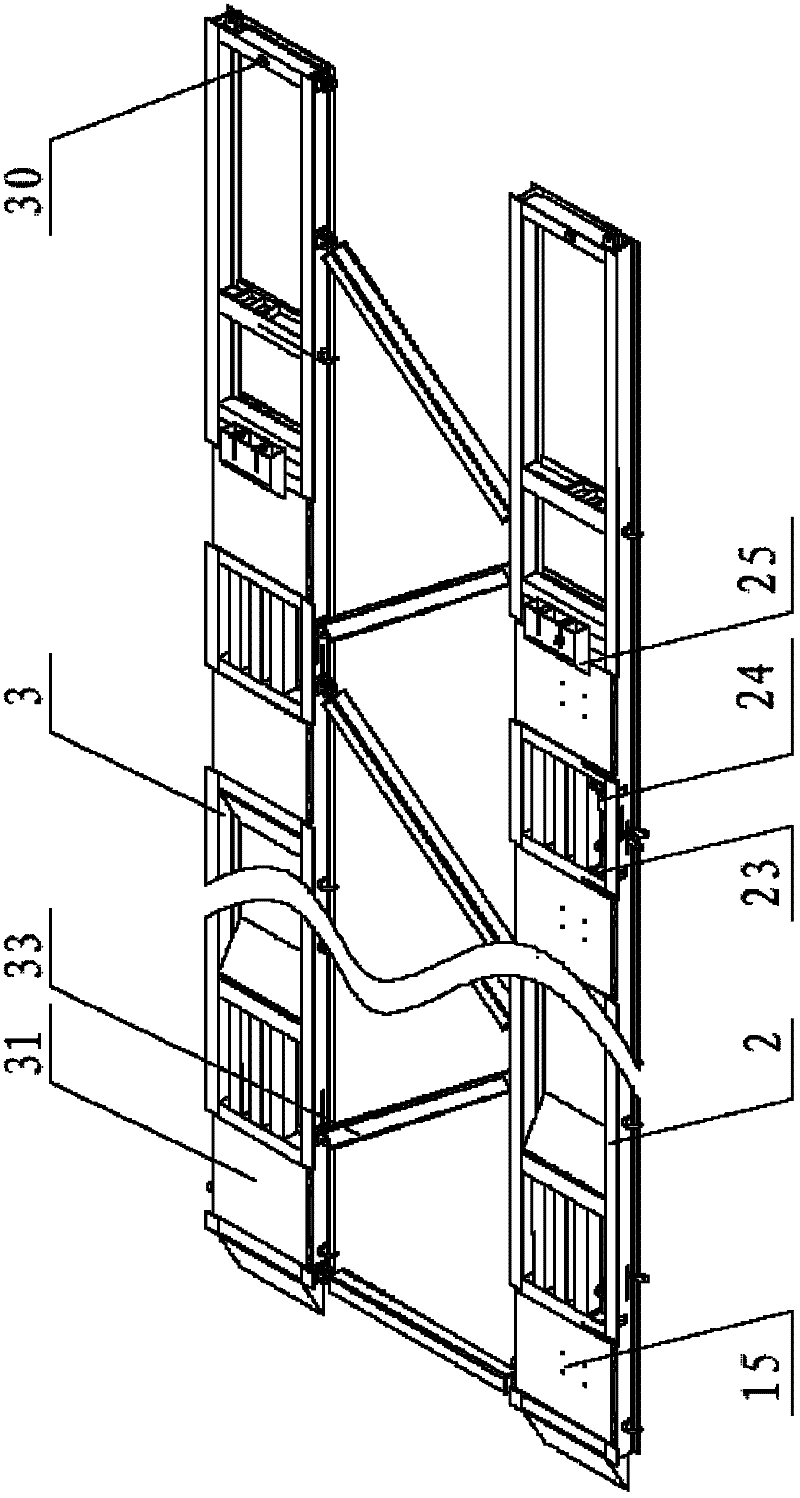

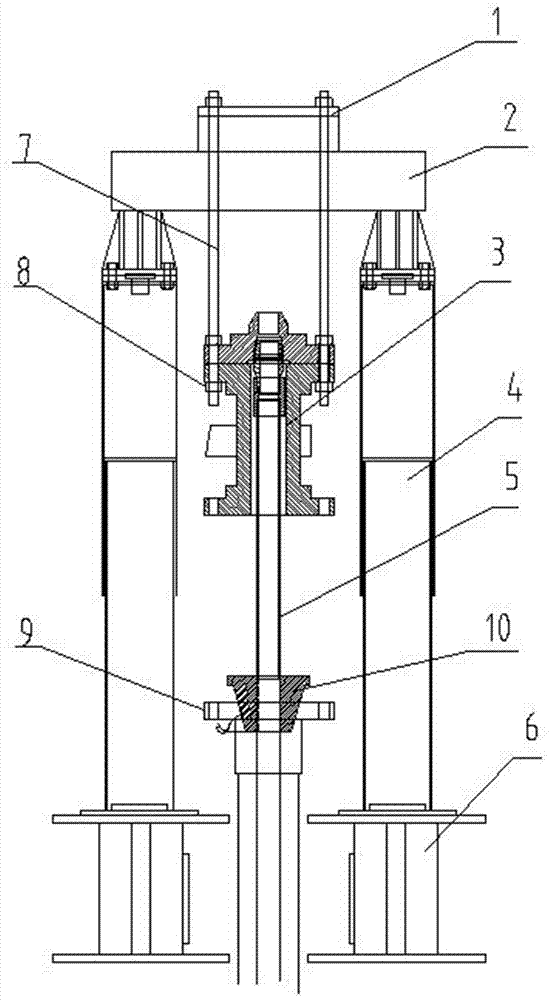

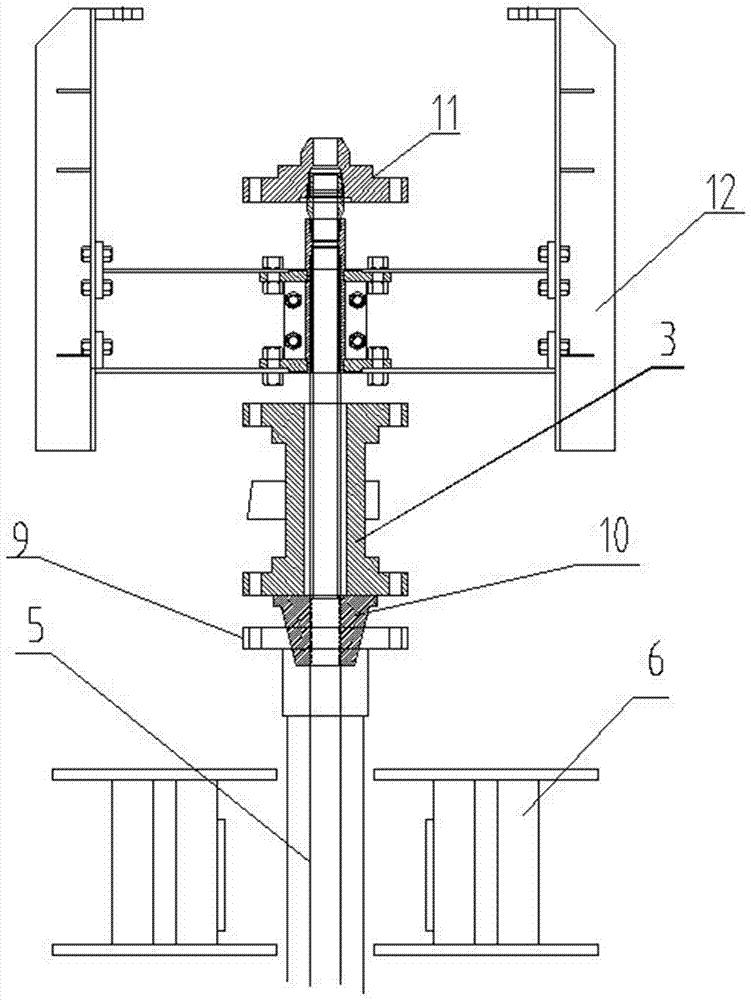

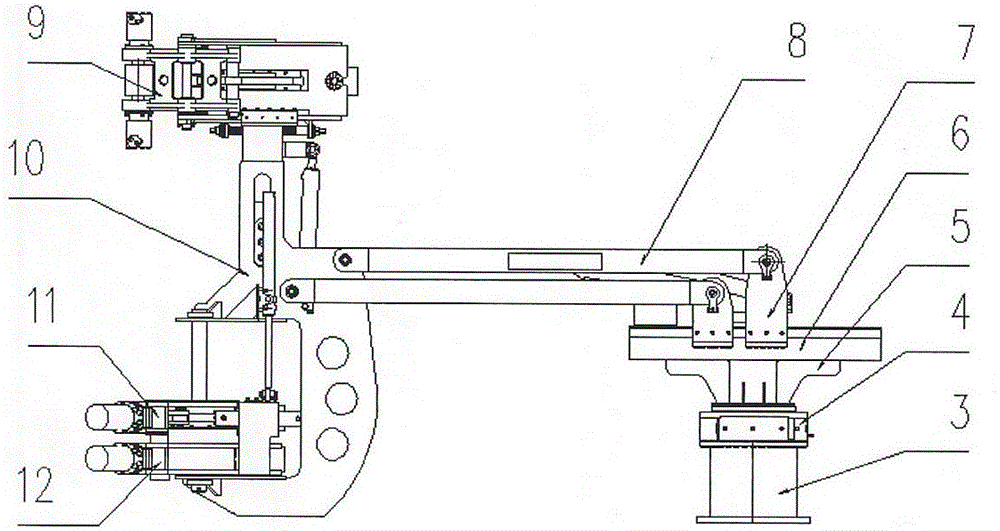

Drill floor well repairing machine without manual operation in well mouth

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

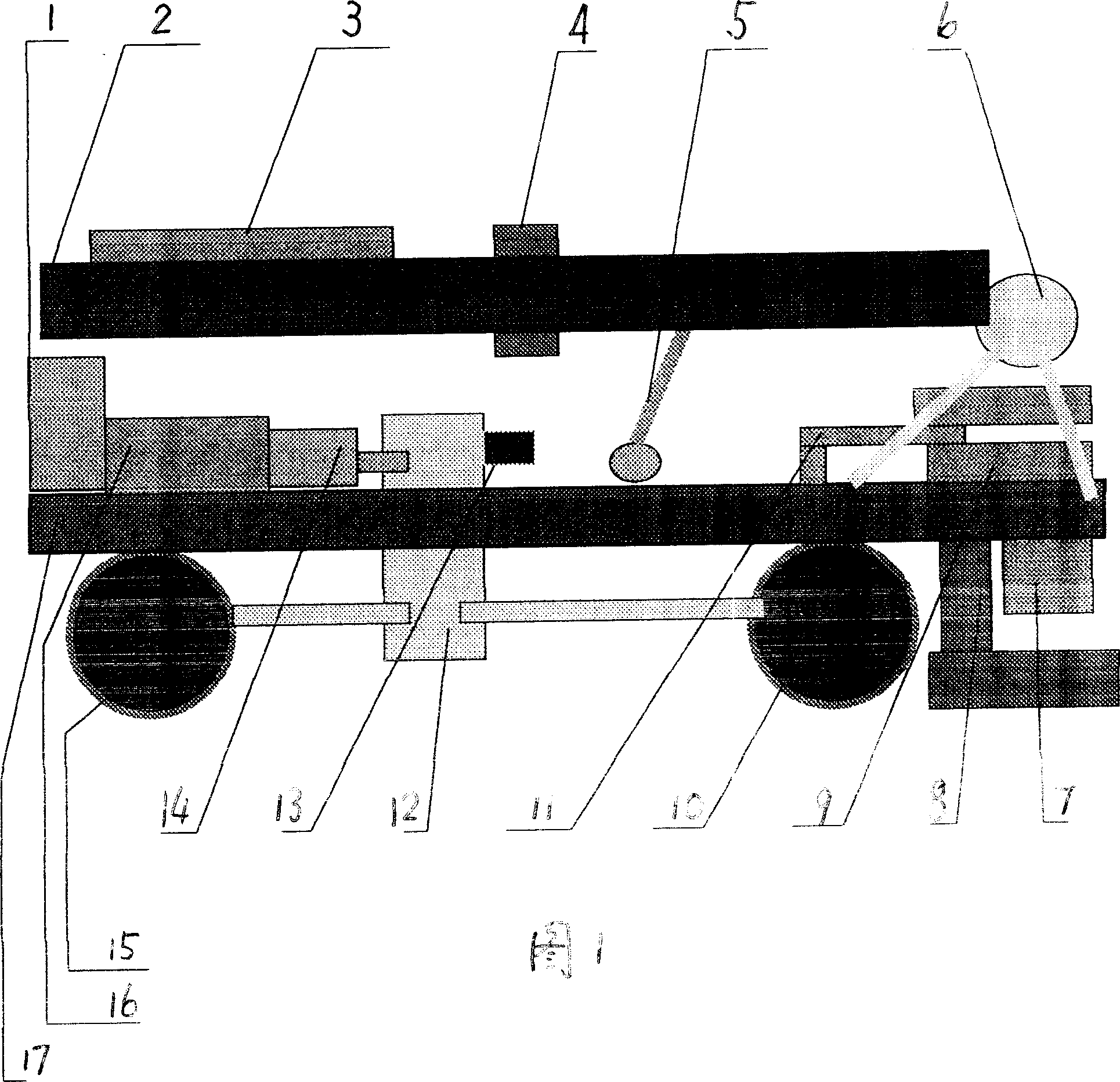

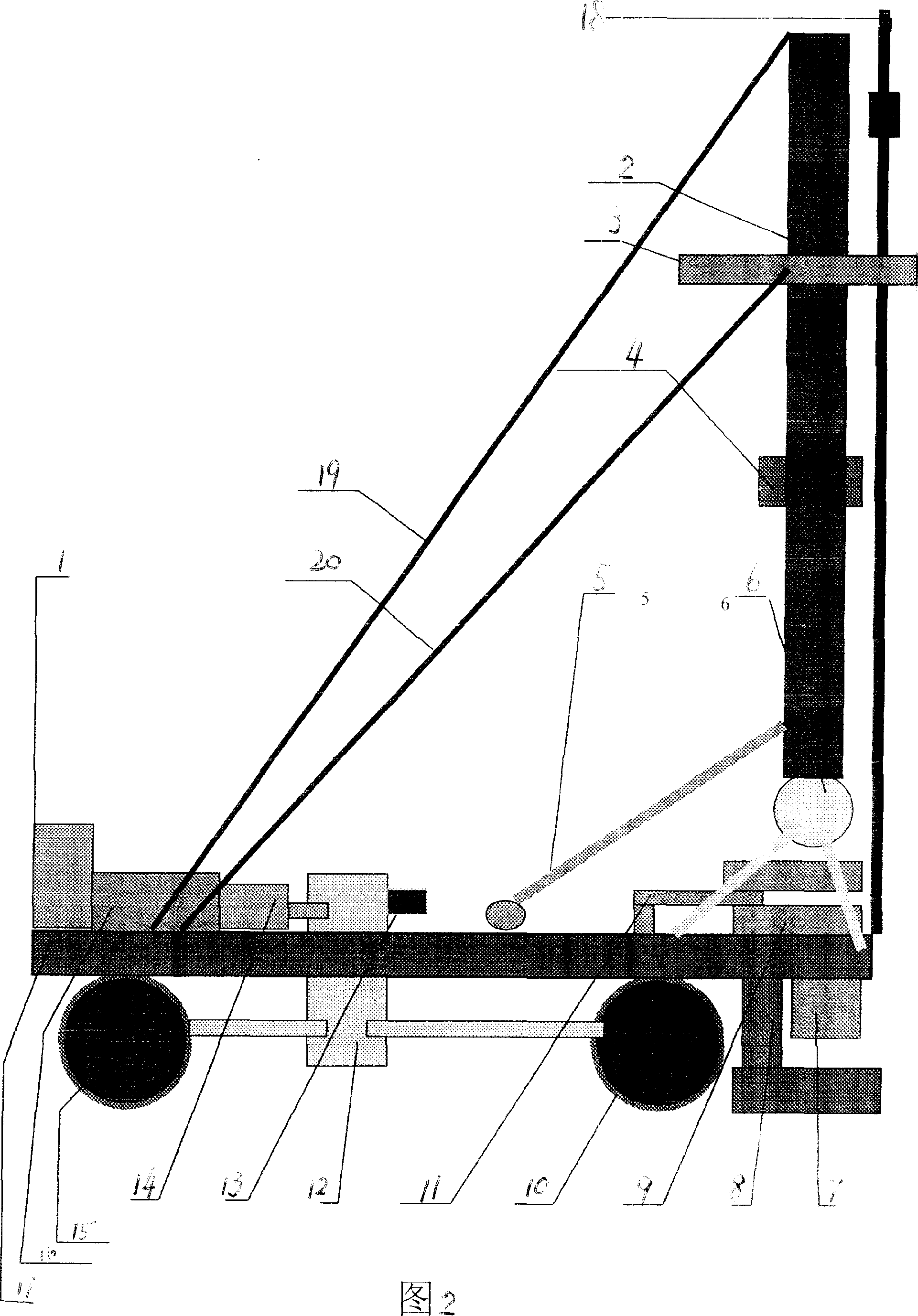

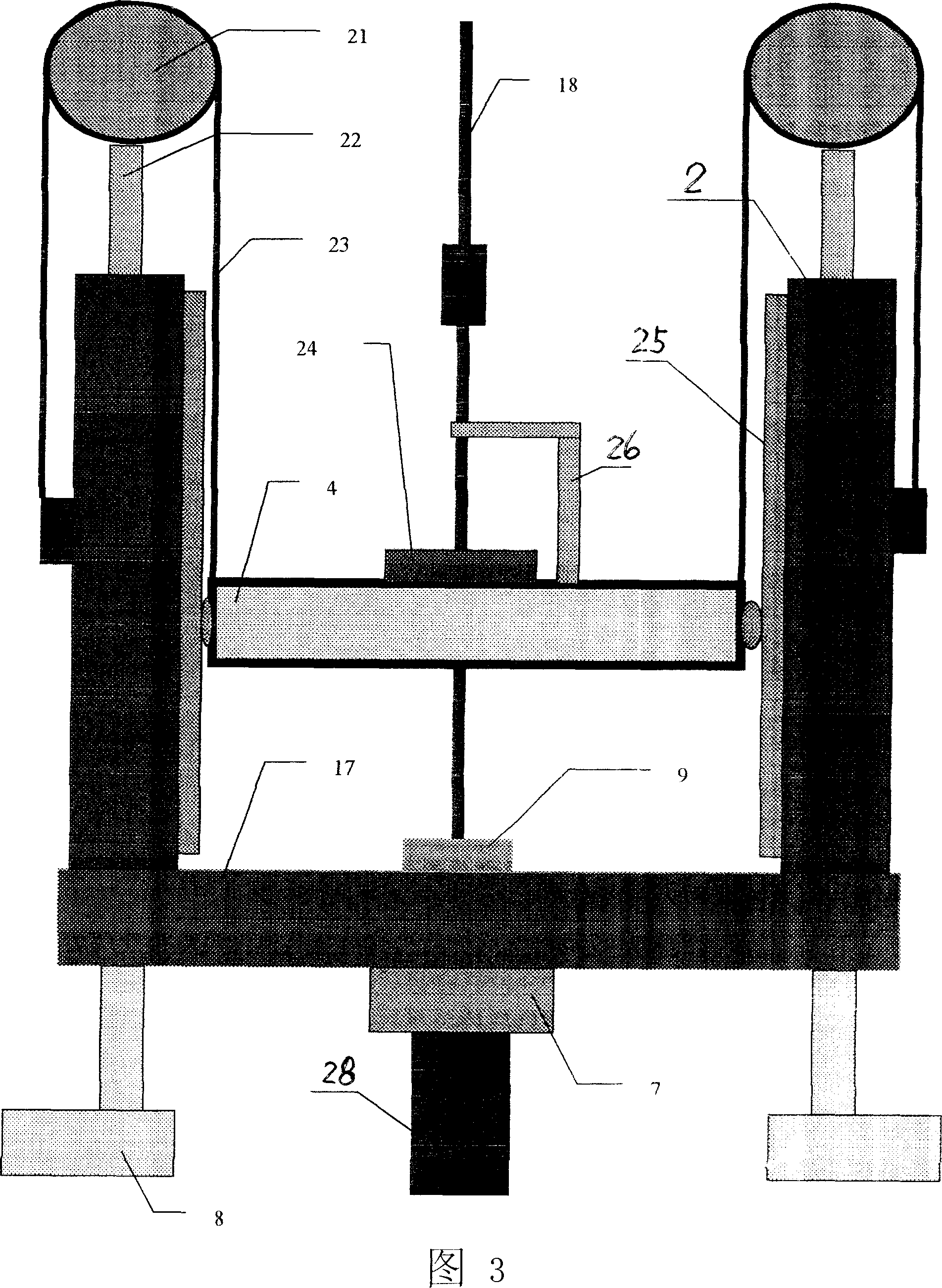

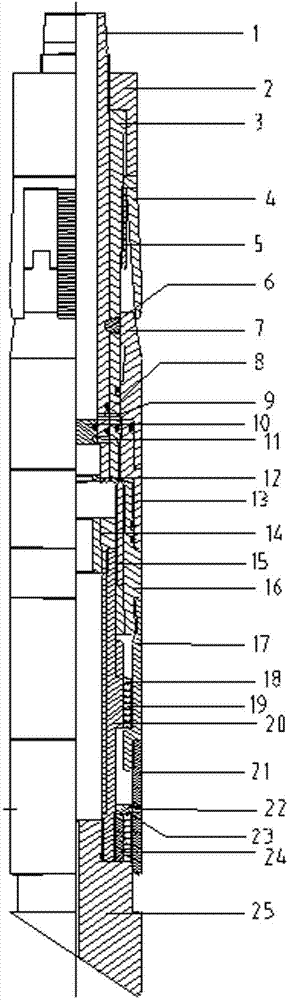

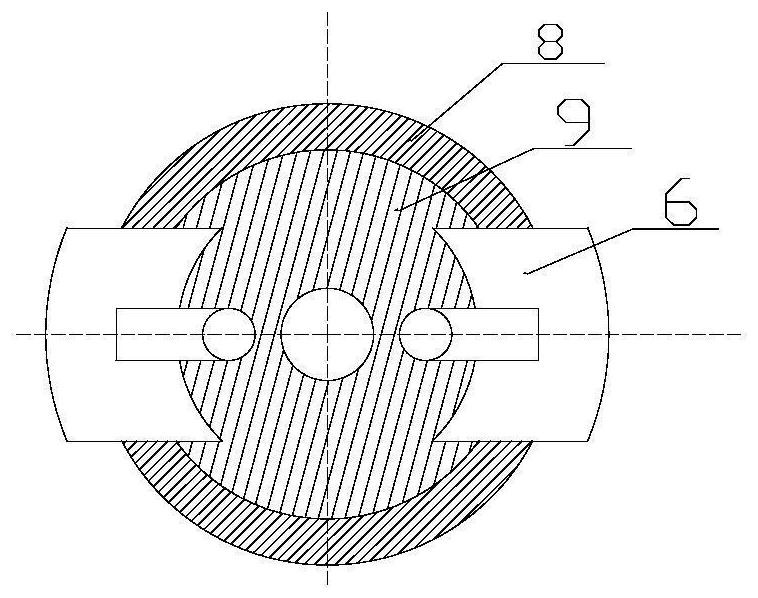

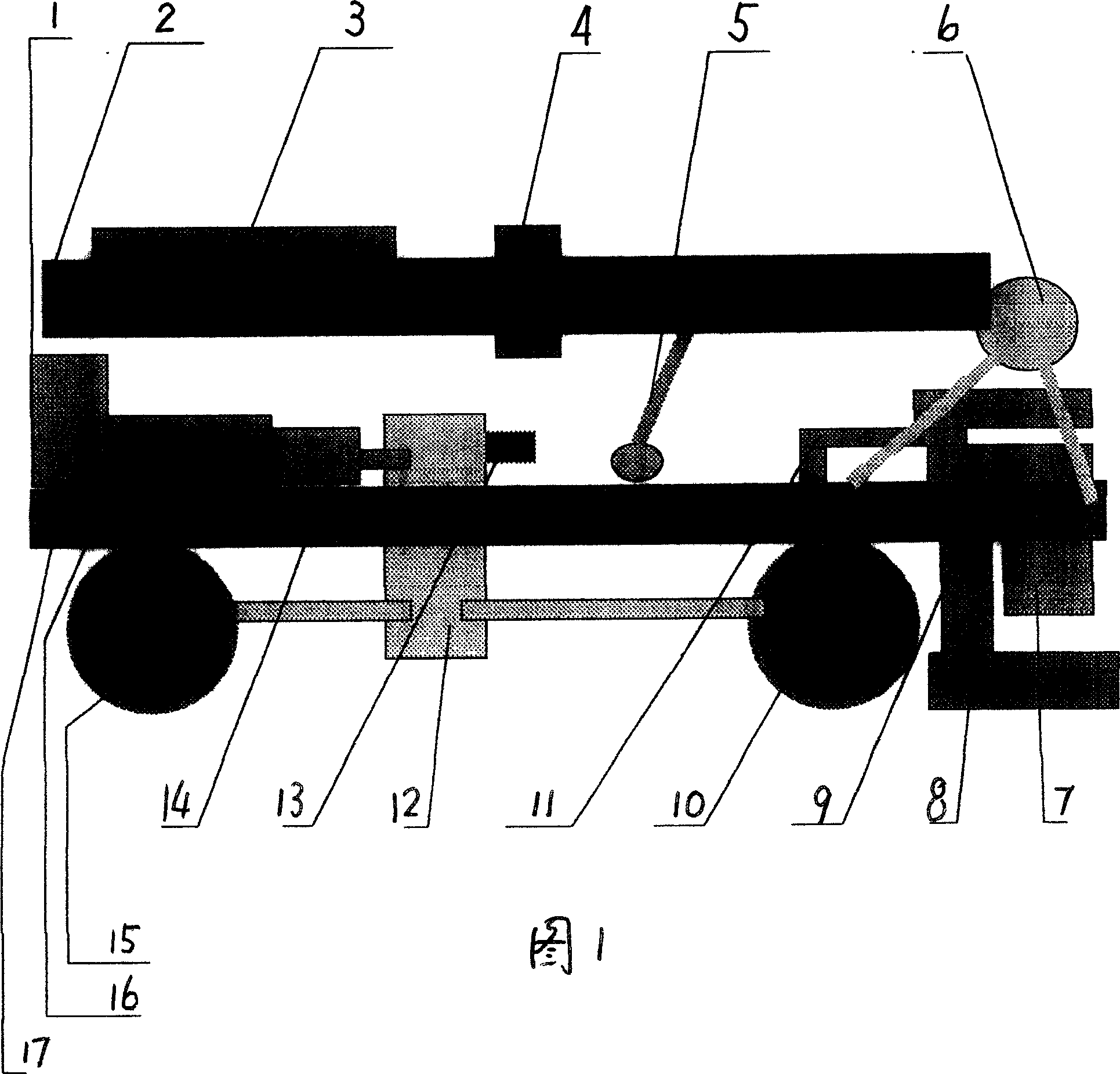

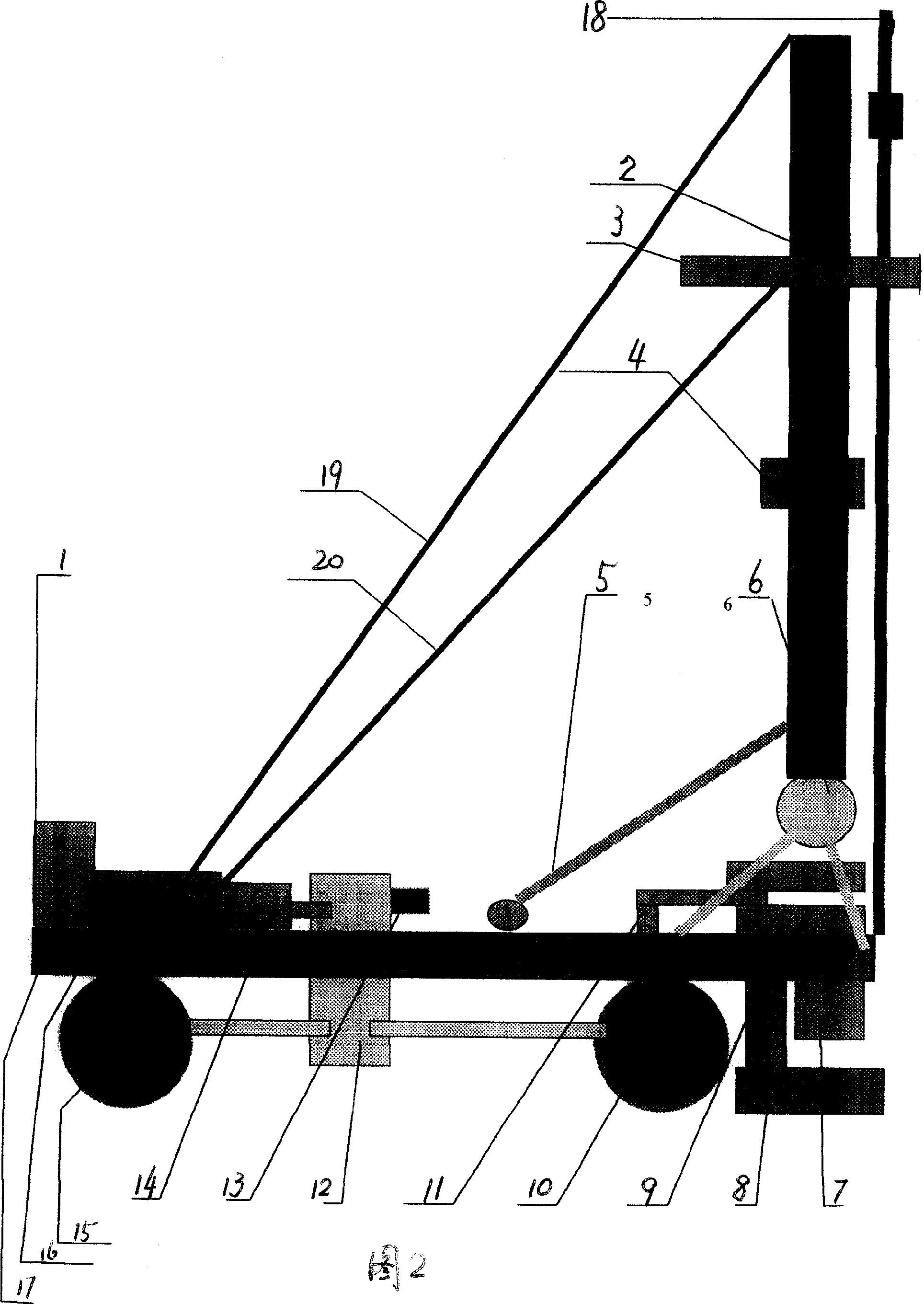

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Automatic elevator for sucker rod in oilfield workover operation and use method

ActiveCN111927342AReduce labor intensityEnsure personal safetyDrilling rodsDrilling casingsGear wheelMachine

The invention relates to the technical field of petroleum workover operation devices and methods, in particular to an automatic elevator for a sucker rod in oilfield workover operation and a use method. According to the technical scheme, the upper part of a large bevel gear is engaged with a bevel pinion, the lower part of the large bevel gear drives clamping jaws, and a stepping motor drives themultiple clamping jaws to advance and retreat through transmission of the bevel pinion and the large bevel gear; an inductive sensor is installed on the lower surface of an elevator box; and the stepping motor, a stepping motor driver and a stepping motor controller are connected with an elevator end cover through bolts, a direct-current power supply is installed on the upper surface of the elevator end cover, the elevator box is installed on a hanging ring through a hanging hook, and the elevator end cover is connected with the elevator box through bolts. The automatic elevator has the advantages that clamping of a push bearing surface shoulder of the sucker rod is completed through the clamping jaws, and the automation of the elevator is achieved through the inductive sensor; and the workover operation efficiency is improved, the labor intensity of workers is reduced, the personal safety of the workers is guaranteed, and the transformation from man-machine collaborative operation toautomation and intelligentization is achieved.

Owner:SLOF KANGBEI IND & TRADING

Temporary plugging agent and preparation method thereof

InactiveCN107288574ARestore permeabilityPrevent flowDrilling compositionSealing/packingFiberSolid particle

The invention provides a temporary plugging agent and a preparation method thereof. With the total mass of the temporary plugging agent as 100wt%, the temporary plugging agent comprises the raw materials of 25-35wt% of a high temperature salt-resistant extra high molecular polymer, 25-30wt% of modified oil soluble resin, 15-20wt% of a cross-linking agent, 5-10wt% of a surface active agent, 1-5wt% of solid particles and 1-5wt% of a fiber temperature-resistant material, wherein the sum of the mass percents of the raw materials of the temporary plugging agent is 100%; and the raw materials of the temporary plugging agent are all solid particles, and the diameters of the particles are 200-300 meshes. The invention further provides the preparation method of the temporary plugging agent. The temporary plugging agent can conduct continuous sand washing on an oil well, change of output after operation is not large, and construction and plug removal can succeed for one time; and the temporary plugging agent is suitable for sand washing construction of a heavy oil well, the sand washing effect is good, sand washing is thorough, the leakage amount is less, and the pump inspection period is prolonged.

Owner:PETROCHINA CO LTD

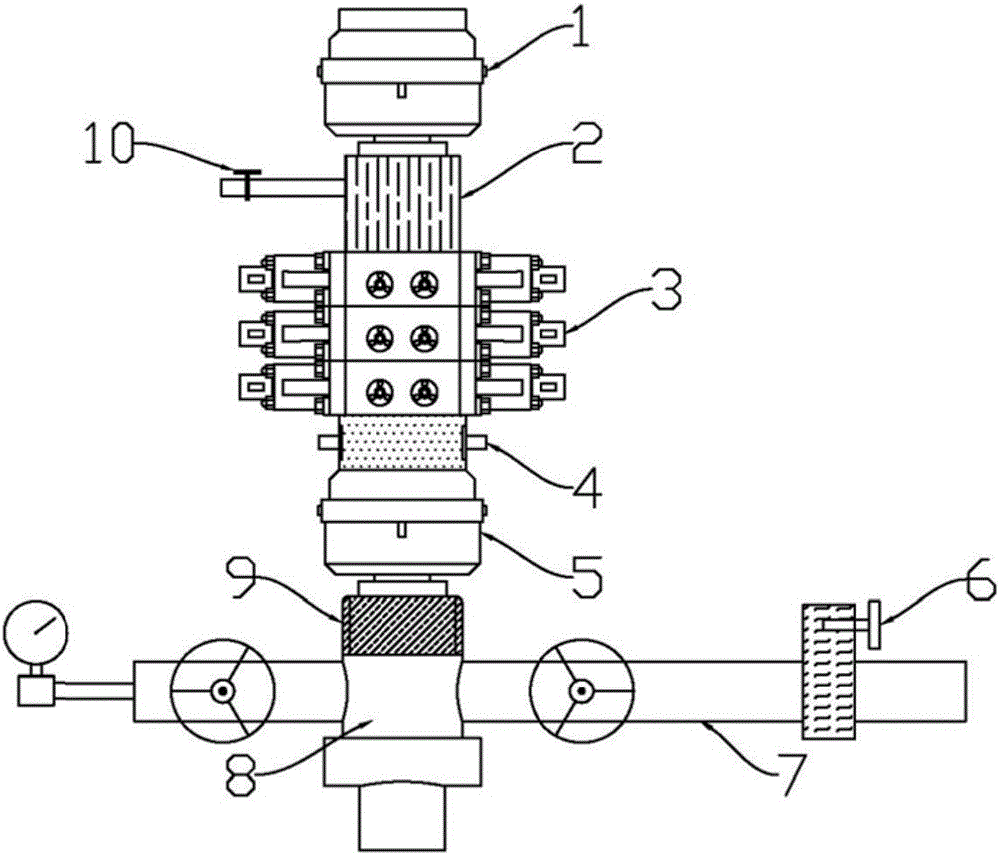

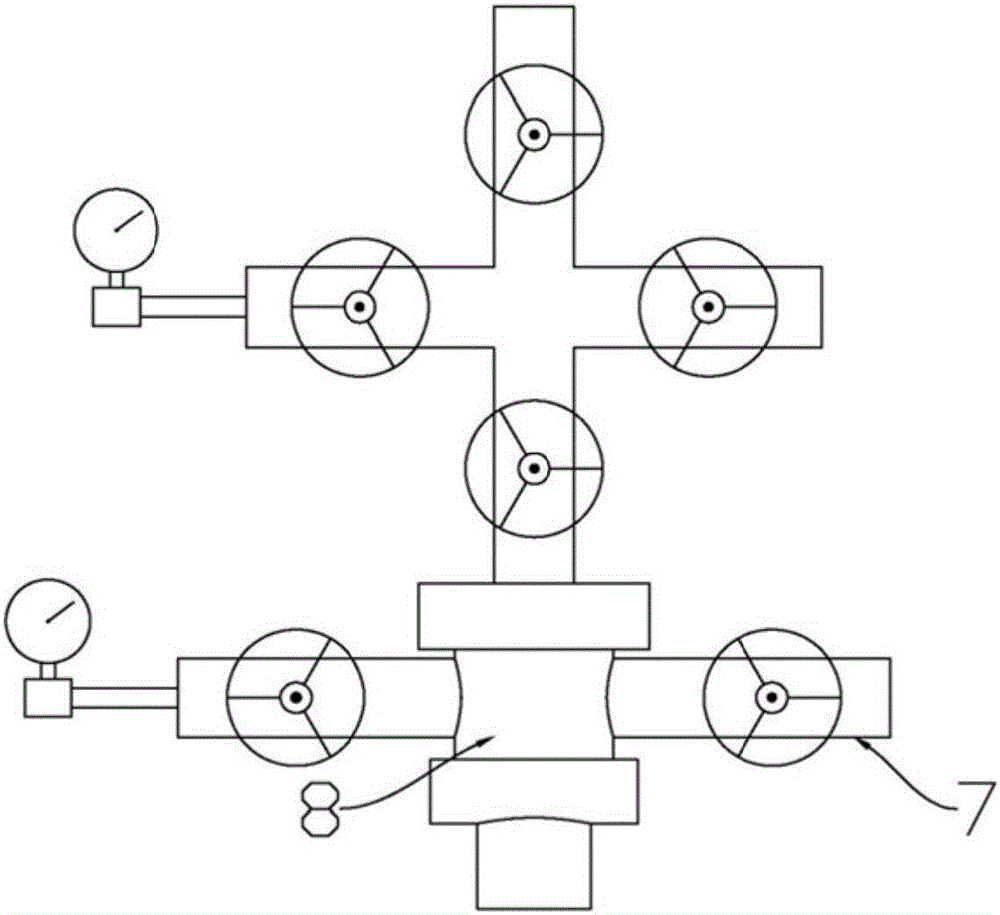

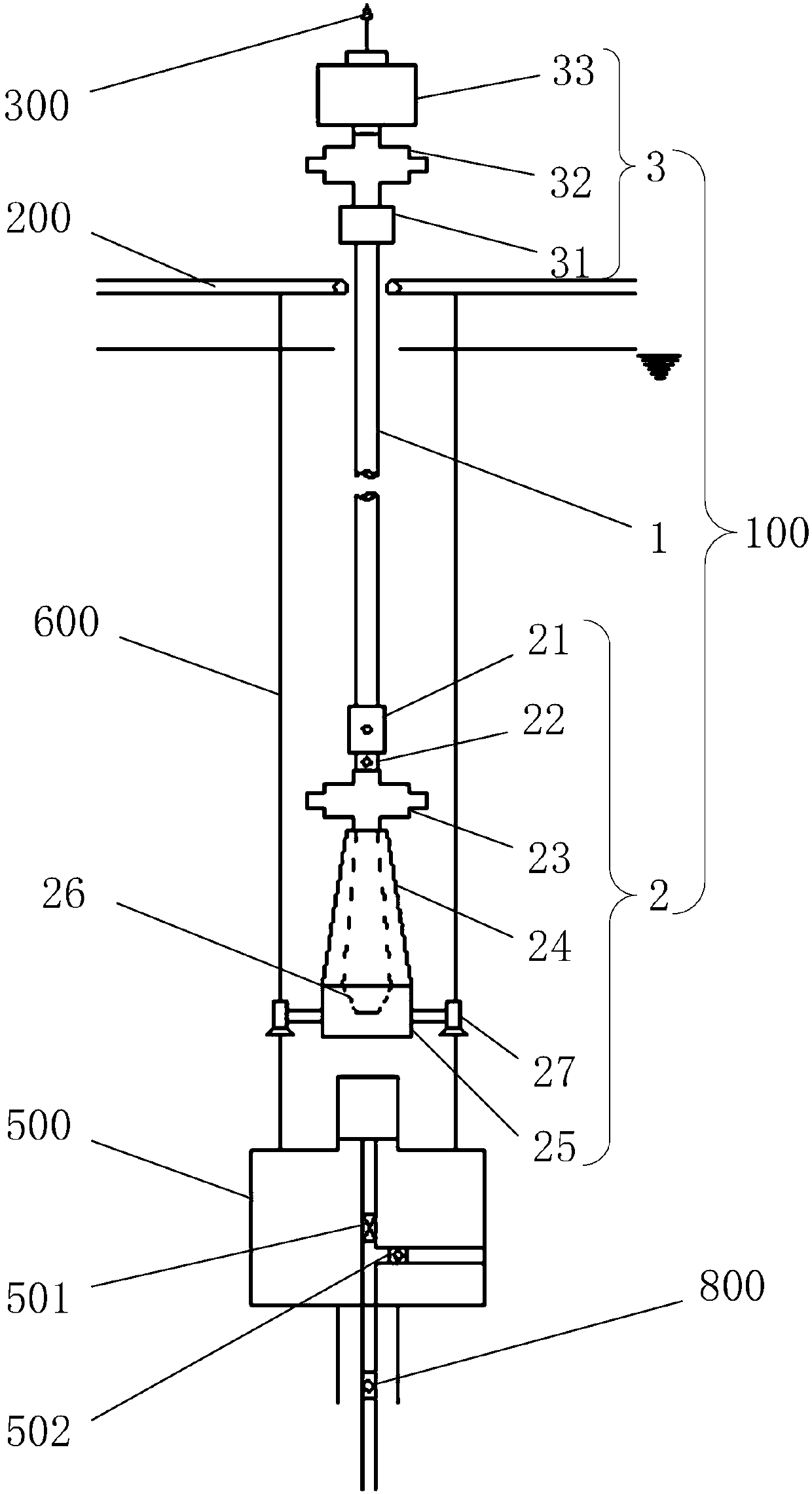

Under-pressure well repairing working device and method of oil-gas field

ActiveCN105804680AReduce consumptionImprove workover efficiencyWell/borehole valve arrangementsSealing/packingEngineeringHydraulic control

The invention discloses an under-pressure well repairing working device and method of an oil-gas field. The device comprises a fixed-pressure valve mounted on a getting-in production pipeline; the upper part of a four-way joint is provided with a coupling detector, a lower annular anti-spraying device, a built-in hydraulic lift sub, a three-flashboard anti-spraying device, a sleeve short section and an upper annular anti-spraying device in sequence; the device further comprises a hydraulic control cabinet; the hydraulic control cabinet is connected with the built-in hydraulic lift sub, the three-flashboard anti-spraying device, the upper annular anti-spraying device and the lower annular anti-spraying device respectively; the method comprises the following steps: S1, a sucker rod works; S2, an oil pumping rod, a pump and other tools work. The well repairing working device and method, disclosed by the invention, completely break through a bottleneck of traditional well repairing work; well repairing pressure can be controlled to be lower than getting-in production pressure so that a pressure grade of needed equipment is reduced, the machining and manufacturing cost of the equipment is greatly reduced and the operation cost of an oil-gas well is reduced; furthermore, the difficulty that the well can be repaired only if the well is closed is innovatively overcome.

Owner:崔斌

Pigging and pipe scraping integrated tool

ActiveCN104763367AReduce the number of timesReduce maintenance costsCleaning apparatusPiggingEngineering

The invention provides a pigging and pipe scraping integrated tool. The pigging and pipe scraping integrated tool comprises a scraping mechanism and a pigging mechanism which are sequentially and fixedly connected from top to bottom, wherein the scraping mechanism comprises a knife rest body, a knife groove is formed in the outer wall of the knife rest body, the scraping mechanism further comprises a scraping knife inserted and connected into the knife groove, and a reed enabling the scraping knife to reset is arranged in the knife groove. The scraping mechanism further comprises a sleeve capable of constraining the scraping knife, wherein the knife rest body is sleeved by the sleeve, and the sleeve can upwards or downwards move till the scraping knife extends out under the elastic force effect of the reed. The pigging and pipe scraping integrated tool performs scraping operation while performing pigging operation, tubular column pulling times can be decreased, the pigging scraping operation efficiency can be improved, and downhole tubular column abrasion can be reduced.

Owner:PETROCHINA CO LTD

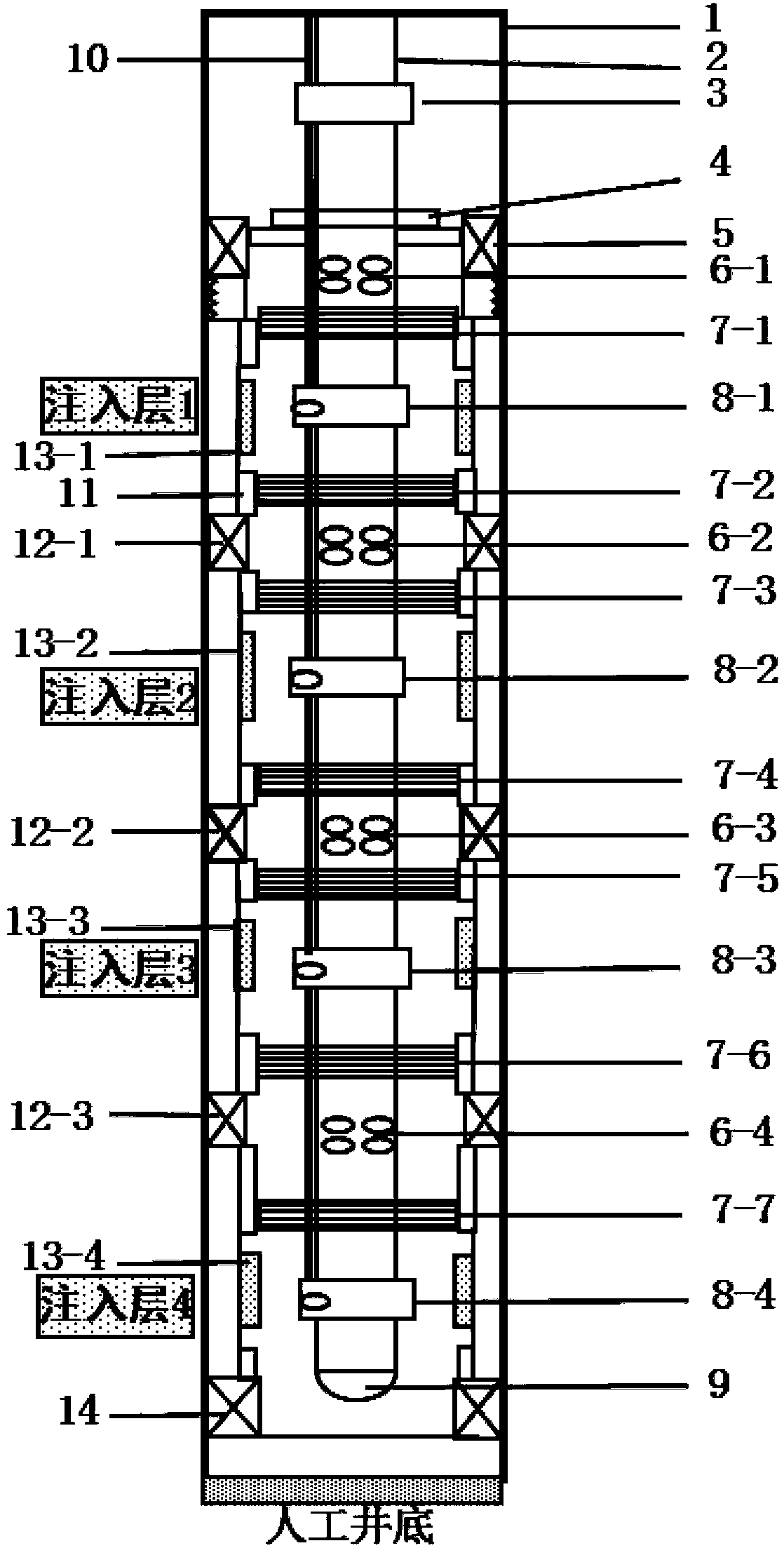

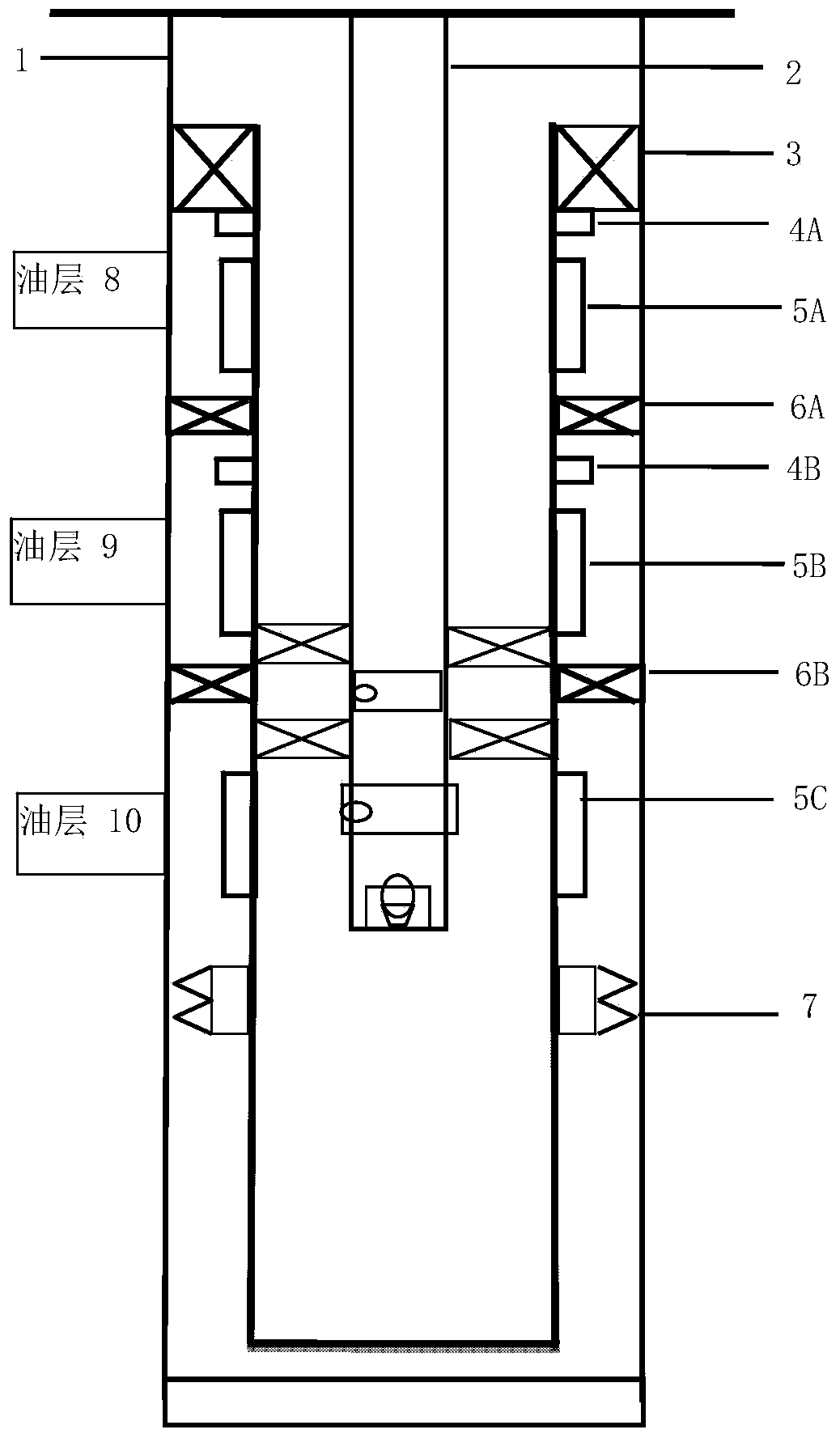

A one-pass pipe string layered water injection sand control backwashing device and a method

ActiveCN108894761AGuaranteed tightnessUnlimited number of levelsFluid removalSealing/packingOperation modeWorkover

The invention discloses a one-pass pipe string layered water injection sand control backwashing device, comprises a reservoir casing which is inserted into the first injection layer, the second injection layer, the third injection layer and the fourth injection layer in turn, wherein the reservoir casing is provided with an inner layer setting sealing water injection backwashing integrated pipe string which has water injection function and is compatible with backwashing well function, and an outer layer sand control pipe string which has independent screen pipe type sand control function; Theinner-layer set seal inspection and backwashing integrated pipe string is arranged in the blind pipe of the outer sand control pipe string, and the upper part of the screen pipe is connected with thestandard oil pipe, and the outer part is connected with the release packer of the outer sand control pipe string, and the release packer and the release packer form an integral whole through the cablesuspension release sealing device. The invention realizes setting and checking seal, ensures sealing effect of packers at all levels, realizes water injection and backwashing function after setting,integrates setting and backwashing operation mode, reduces risk of later operation, and improves workover efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +1

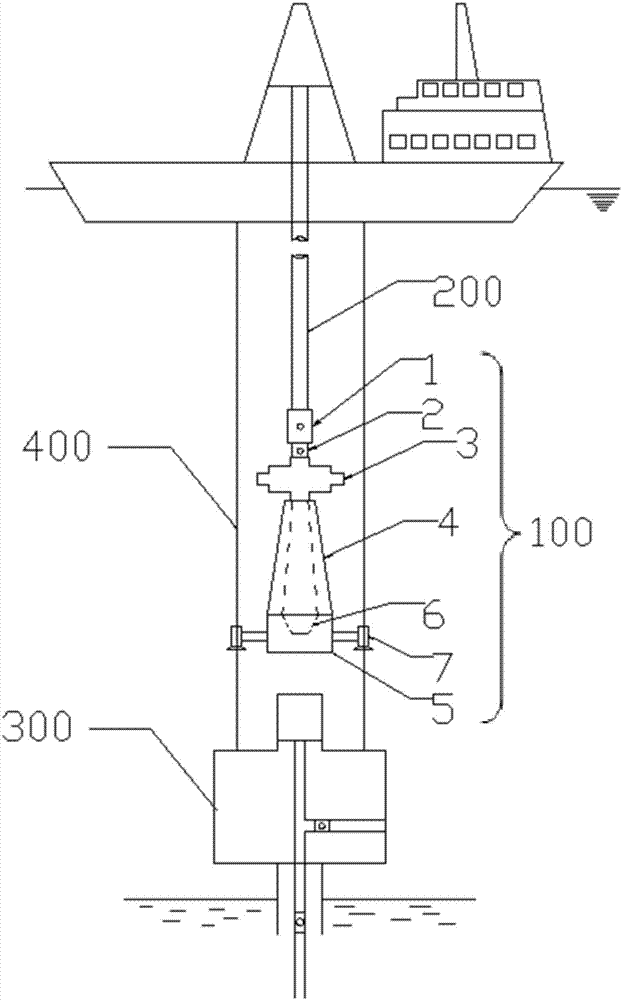

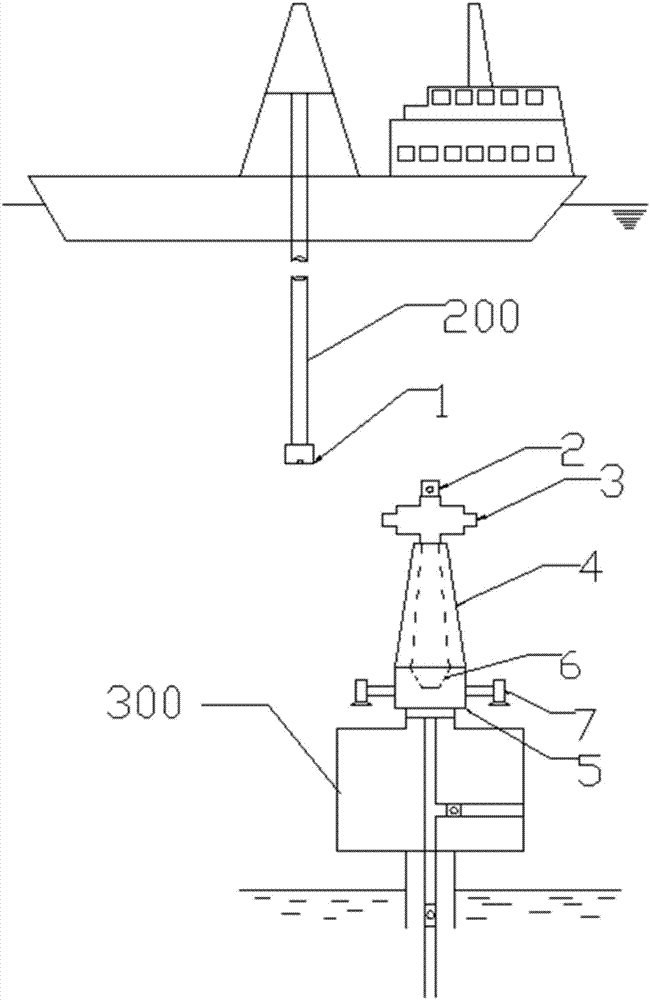

Underwater well repair assembly

The invention relates to an underwater well repair assembly. The underwater well repair assembly comprises a safety joint, a blowout control valve, a totally-closed shear blade blowout preventer, a stress joint and a tie-back device which are sequentially connected from top to bottom, as well as a guiding short circuit arranged in the stress joint, wherein the safety joint is used for being connected with a drill pipe; and the tie-back device is used for being connected with an underwater Christmas tree. According to the underwater well repair assembly, well repair operation of a deep water oil and gas field can be performed by adoption of an active-service engineering ship, and a large-scale floating-type drilling platform or a special well repair ship for building is not required to be used, so that the operation cost can be greatly lowered, and the well repair efficiency is improved. As the safety joint is arranged, in case of such severe working conditions as typhoon during operation, emergency disposal can be performed, temporary well abandoning can be quickly and reliably conducted, the engineering ship or the drilling platform is withdrawn, and the safety risks during operation can be reduced. The underwater well repair assembly can be used for the engineering ship or the drilling platform, and can be widely applied to well repair operation of the deep water oil and gas field adopting an underwater production system development mode.

Owner:CHINA NAT OFFSHORE OIL CORP +1

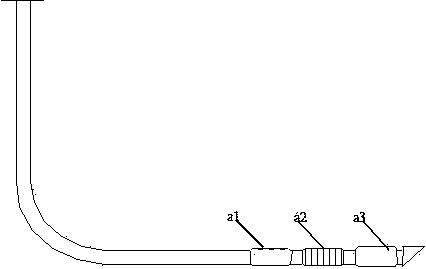

Centralizing string and restoring string for horizontal well casing pipe dislocation and restoring process of centralizing string and restoring string

ActiveCN102852478AChange the unfavorable situationWith secondary pressure functionBorehole/well accessoriesHorizontal wellsOil field

The invention discloses a centralizing string and a restoring string for horizontal well casing pipe dislocation and a restoring process of the centralizing string and the restoring string so as to solve the problem that existing dislocation wells with the casing pipe dislocation and inner diameter coincidence degree ranging from 30-50% in an oil field are incapable of being centralized and restored. The centralizing string comprises a booster, a hydraulic anchor and an oil pipe, and an eccentricity centralizing hanger, the booster and the hydraulic anchor are sequentially connected through the oil pipe. The restoring string matched with the centralizing string in use comprises an oil pipe and a casing pipe restoring tool which are connected, an insertion pipe is connected at the bottom of a cylinder of the casing pipe restoring tool, and a casing pipe is inserted into an outer positioning cylinder of the eccentricity centralizing hanger. The restoring process is particularly applicable to thermal recovery horizontal well casing pipe dislocation restoring works and similarly applicable to other casing pipe dislocation horizontal wells. The centralizing string and the restoring string and the restoring process can be used for effectively restoring the dislocation casing pipe at a horizontal segment of the horizontal well, have no chemical pollution to an oil layer and are wide in application range, simple in construction steps and capable of effectively reducing production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

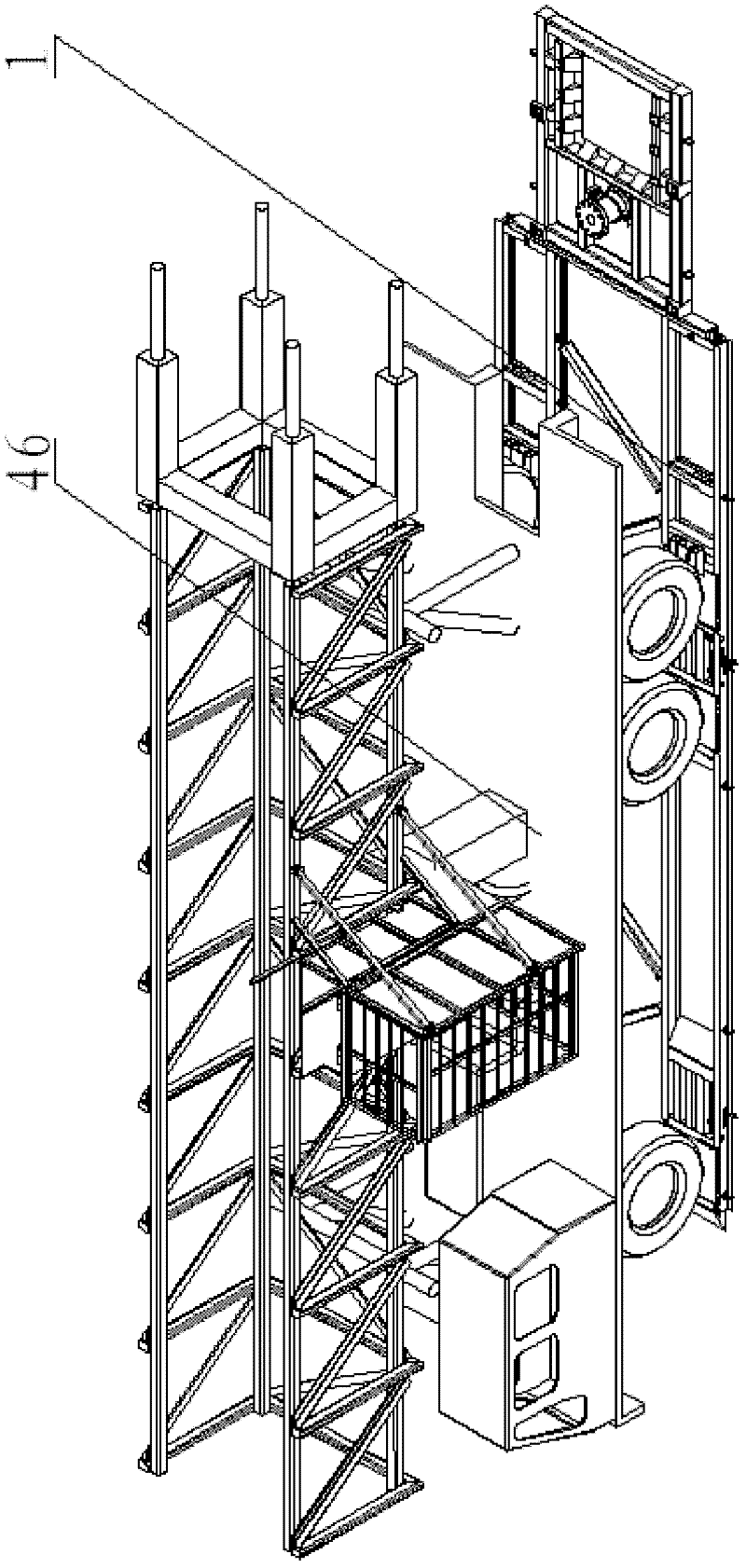

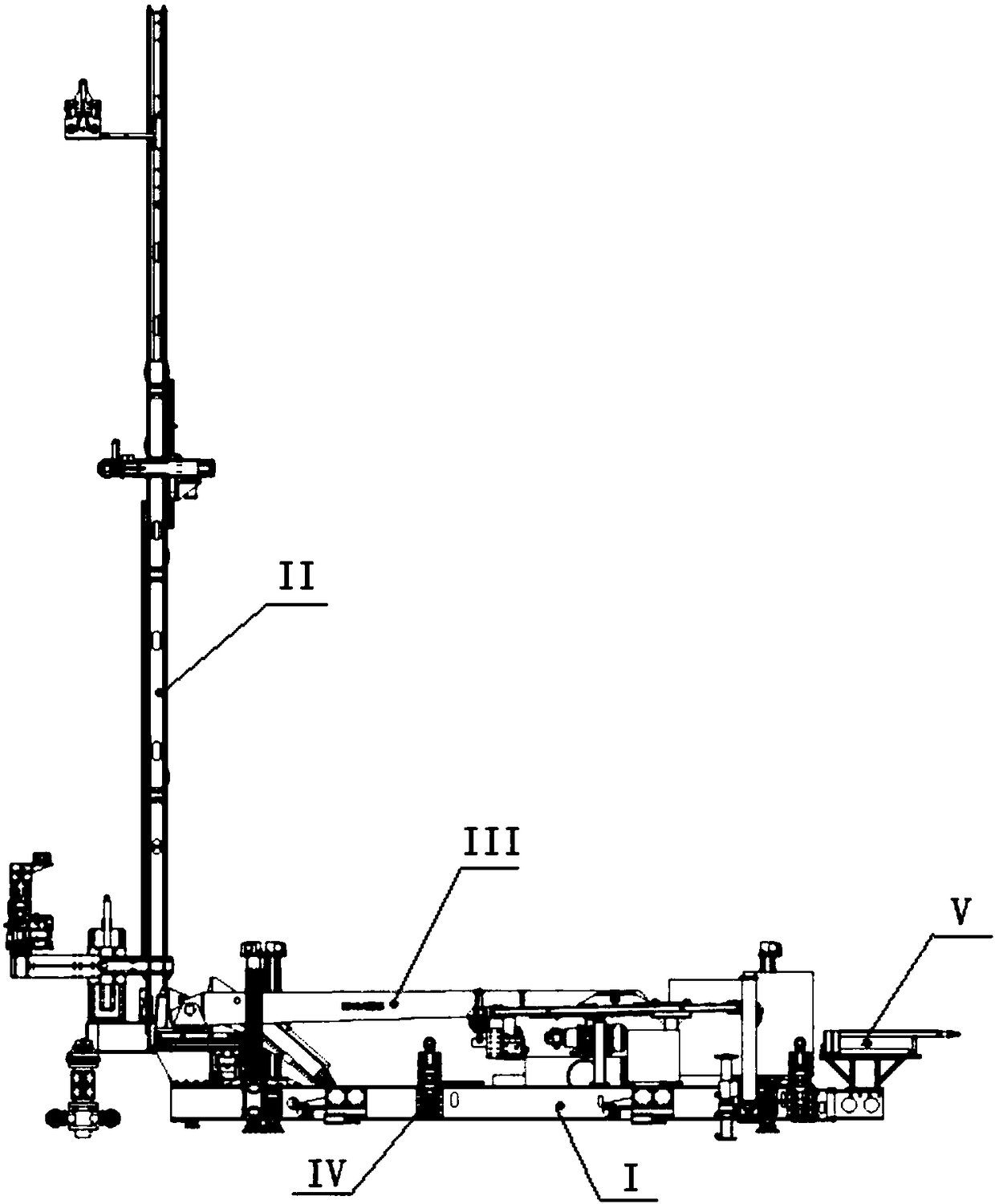

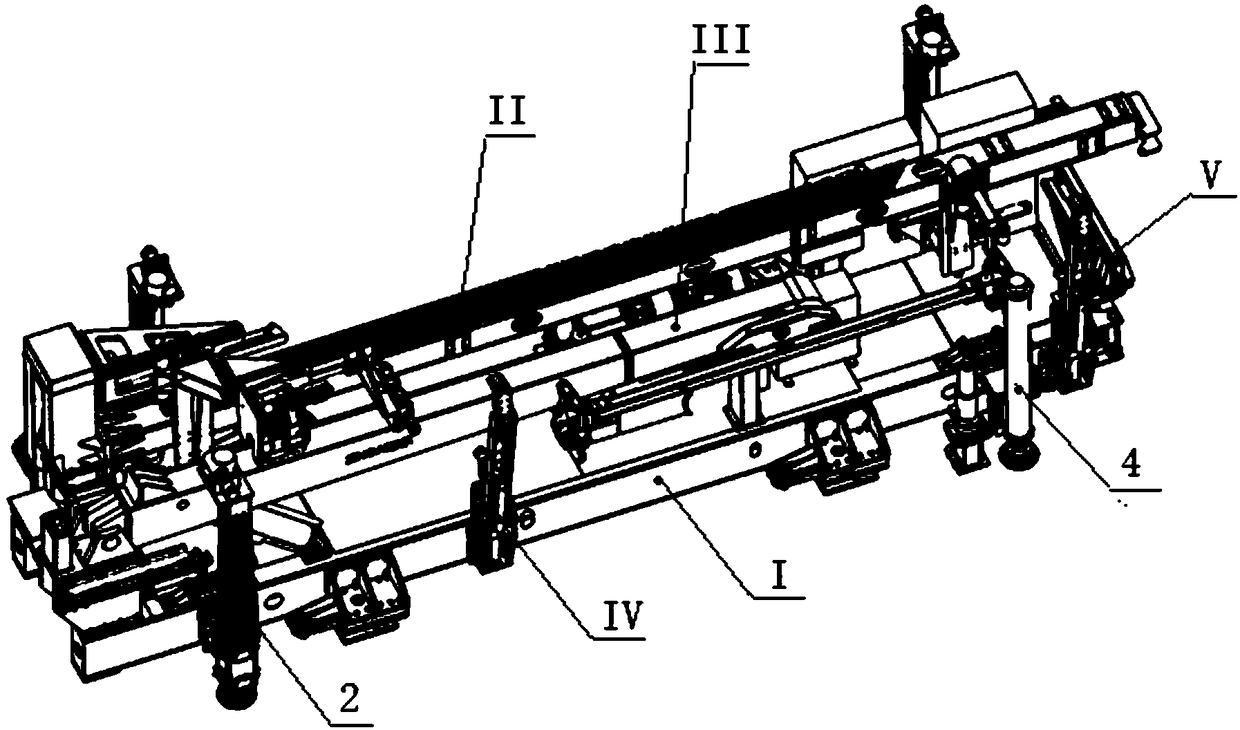

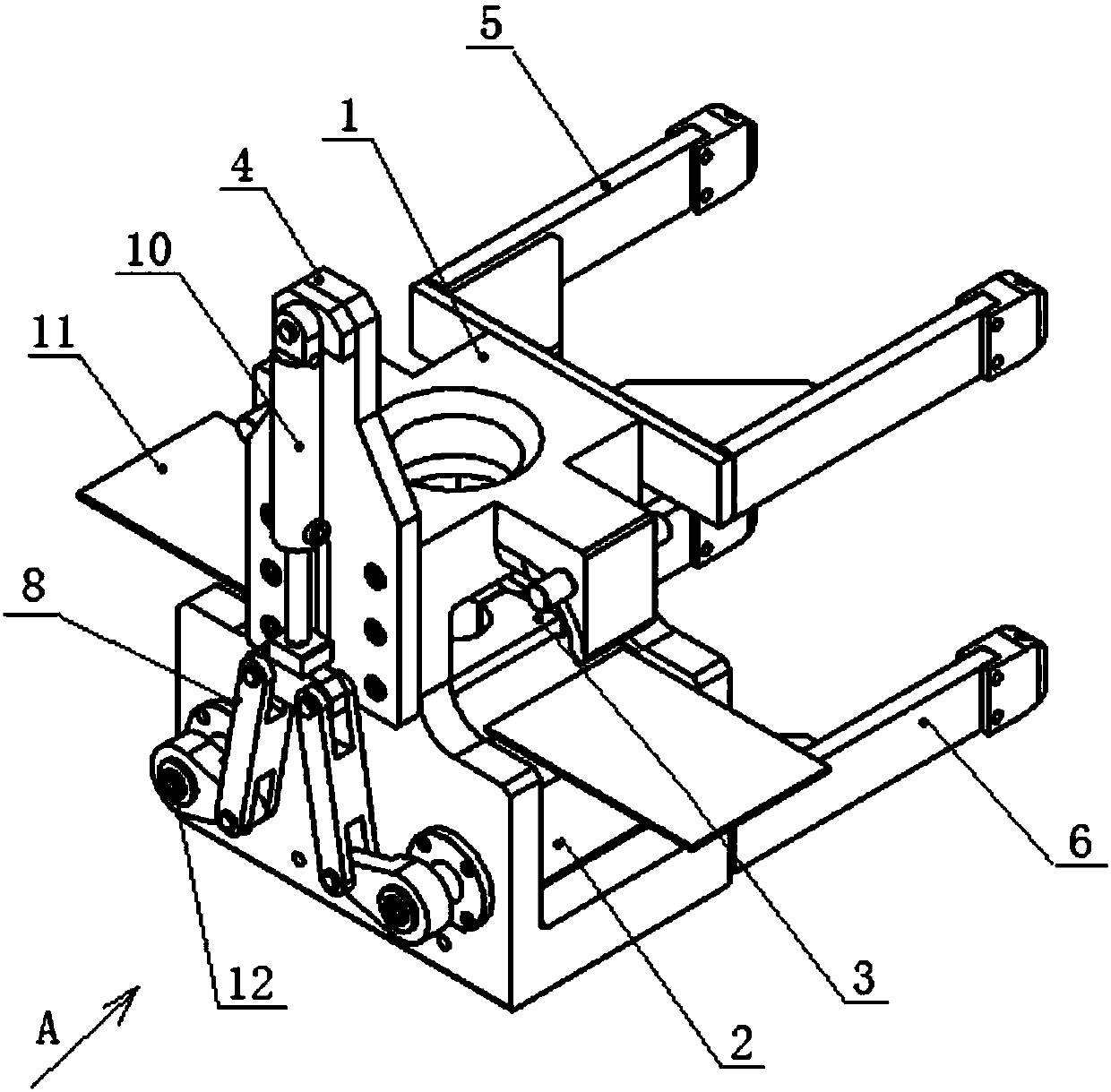

Well repair well mouth unmanned operation platform

PendingCN111794697AReliable completionImprove workover efficiencyDrilling rodsSealing/packingMarine engineeringOil field

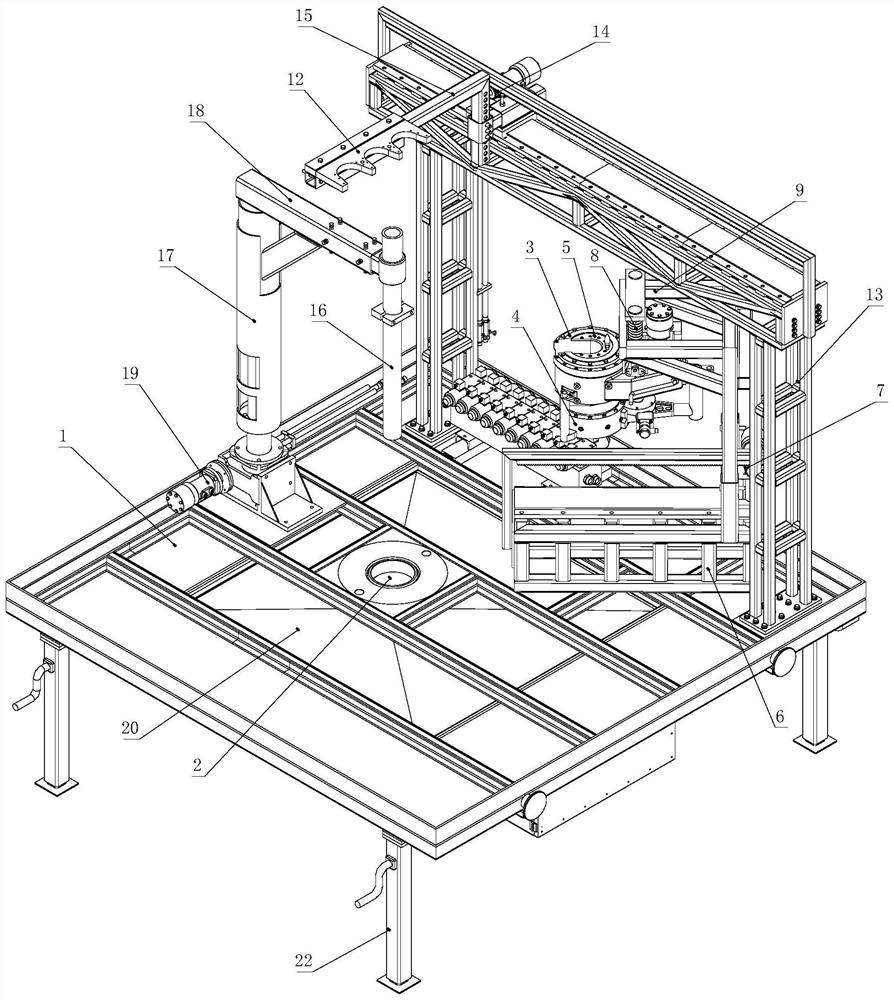

The invention relates to the technical field of oil field oil recovery, and specifically relates to a well repair well mouth unmanned operation platform. According to the adopted technical scheme, thewell repair well mouth unmanned operation platform comprises a work table; a flange allowing a pipe rod to penetrate is arranged on the middle portion of the work table; a hydraulic tong assembly anda pipe push assembly are further arranged on the work table; the hydraulic tong assembly is used for detaching and connecting the pipe rod; a hydraulic tong of the hydraulic tong assembly can move inthe radial direction of the flange; and the pipe push assembly is used for pushing the pipe rod away from the work table. By means of the well repair well mouth unmanned operation platform, the piperod lifting and placing work during oil field well repair can be effectively and reliably completed, mechanical and automated pipe rod lifting and placing are achieved, and the well repair well mouthunmanned operation platform has the characteristics of being easy, rapid and safe to operate. In the whole operation process, the position of well repair platform is relatively fixed, it is avoided that the device position is adjusted during each time of well repair, repeatability of the operation is good, and the well repair efficiency is high.

Owner:克拉玛依众城石油装备研究院股份有限公司

Device for adjusting centration of complete vehicle-mounted service machine to wellhead

InactiveCN102305035AAchieve fixationReduce labor intensityDrilling rodsDerricks/mastsCentrationRolling resistance

The invention discloses a device for adjusting the centration of a complete vehicle-mounted service machine to a wellhead in order to solve the problem that the conventional vehicle-mounted service machine is centered to a wellhead difficultly. In the device, a vehicle body adjusting and positioning unit and a wellhead positioning unit are integrated; an installation position of the device for adjusting the centration of the complete vehicle-mounted service machine to the wellhead is determined through a wellhead base positioning device; a horizontal position of the complete machine is adjusted by observing a universal leveling bubble until the device is horizontal; and the complete vehicle-mounted service machine is driven to the vehicle body adjusting and positioning unit, so that wheels are positioned on power sliding blocks at a driving end and a driven end and the service machine can be limited by front and rear limiting blocks, and thus a front-rear position of the service machine is determined. On the premise of defining left and right offset of the service machine, the left and right movement of the vehicle body is realized by adjusting a manual double-function hydraulic pump, so that the adjustment of the left position and the right position of the service machine is realized. The device has a simple structure and is convenient to install; due to rolling friction, a friction force is reduced; therefore, the wellhead centration operation saves power and is simple and accurate, and the working efficiency of well repair is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

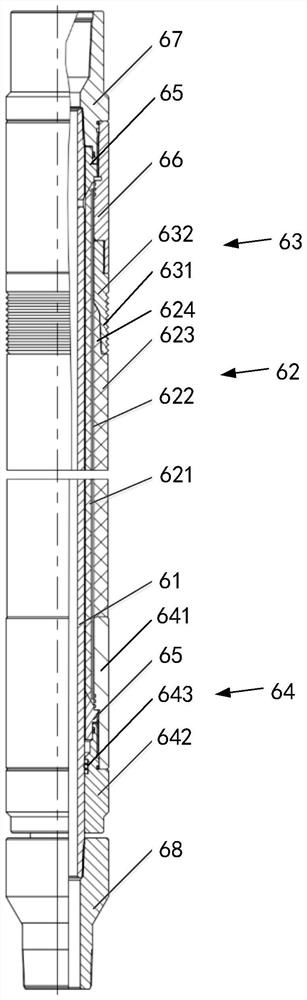

Deformed casing repairing device

InactiveCN105569596ARepair purpose controllableImprove workover efficiencyBorehole/well accessoriesUpper jointControl engineering

The invention discloses a deformed casing repairing device and belongs to the technical field of deformed casings. The deformed casing repairing device comprises an antisticking hydraulic anchor, a travel booster, a hydraulic accumulator, an intelligent commutator, a hydraulic impactor and a split expansion pipe joint, wherein a lower joint of the antisticking hydraulic anchor is in seamless joint with an upper joint of the travel booster, the lower end of the travel booster is in seamless joint with the upper end of the hydraulic accumulator, and the lower end of the hydraulic accumulator is in seamless joint with the upper end of the intelligent commutator; the lower end of the intelligent commutator is in sealed joint with the upper end of the hydraulic impactor, and a sixth impact cavity of the intelligent commutator is in communicated joint with a hydraulic impactor core tube of the hydraulic impactor; an impact head of the hydraulic impactor is contacted with a boosting block on the split expansion pipe joint. The provided deformed casing repairing device can overcome defects of a conventional repairing technology, continuously repairs a casing and is controllable in repairing, high in repairing efficiency and low in repairing cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

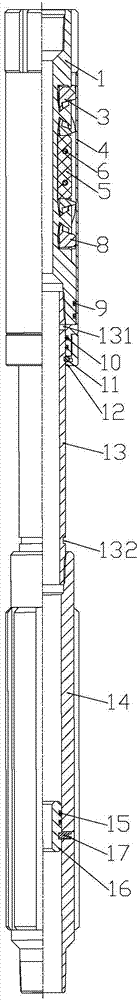

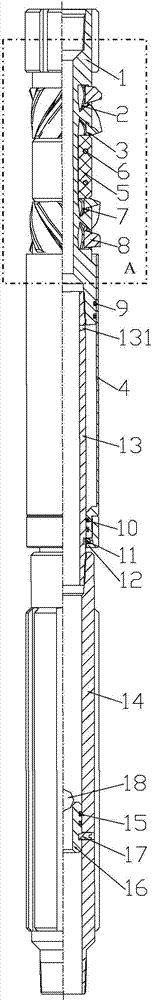

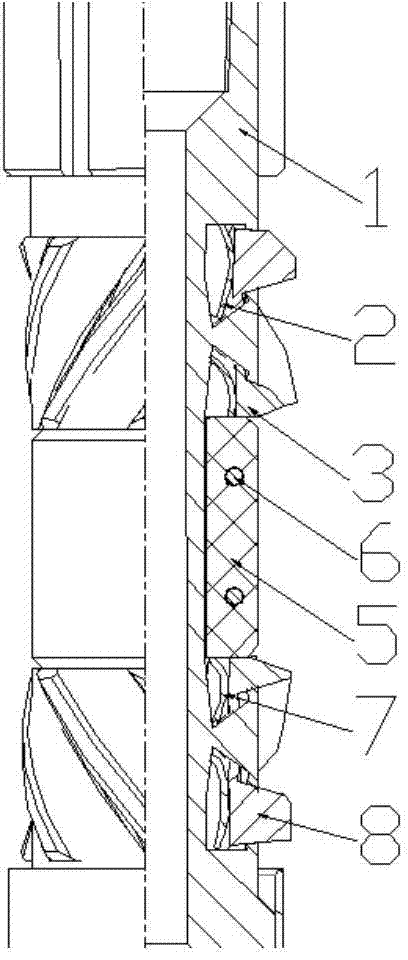

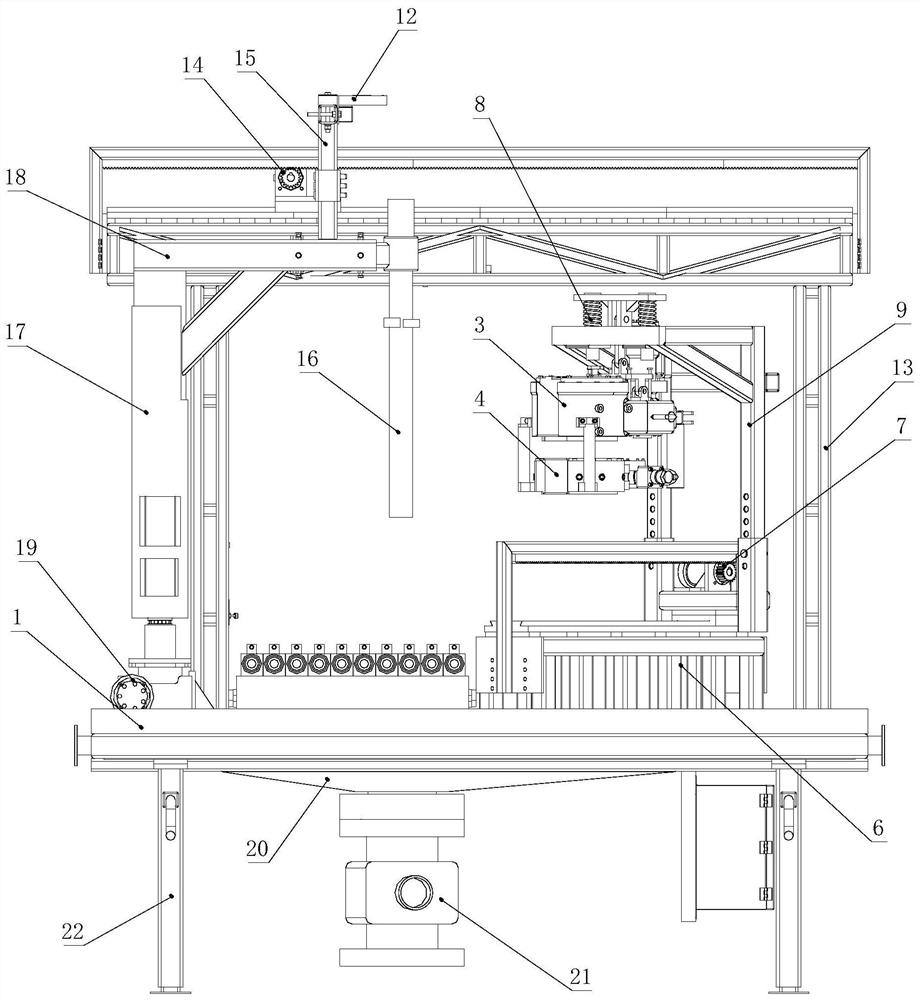

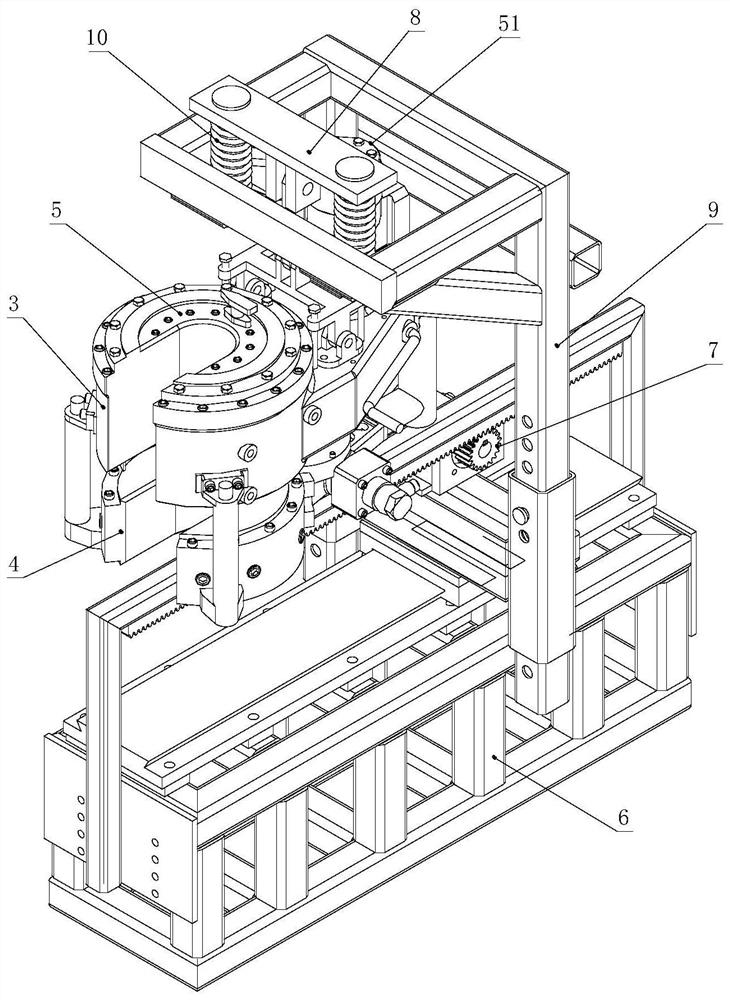

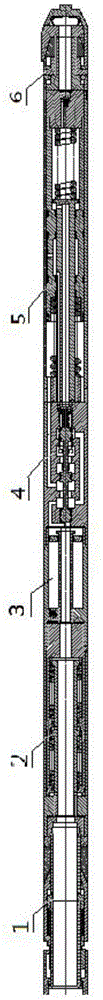

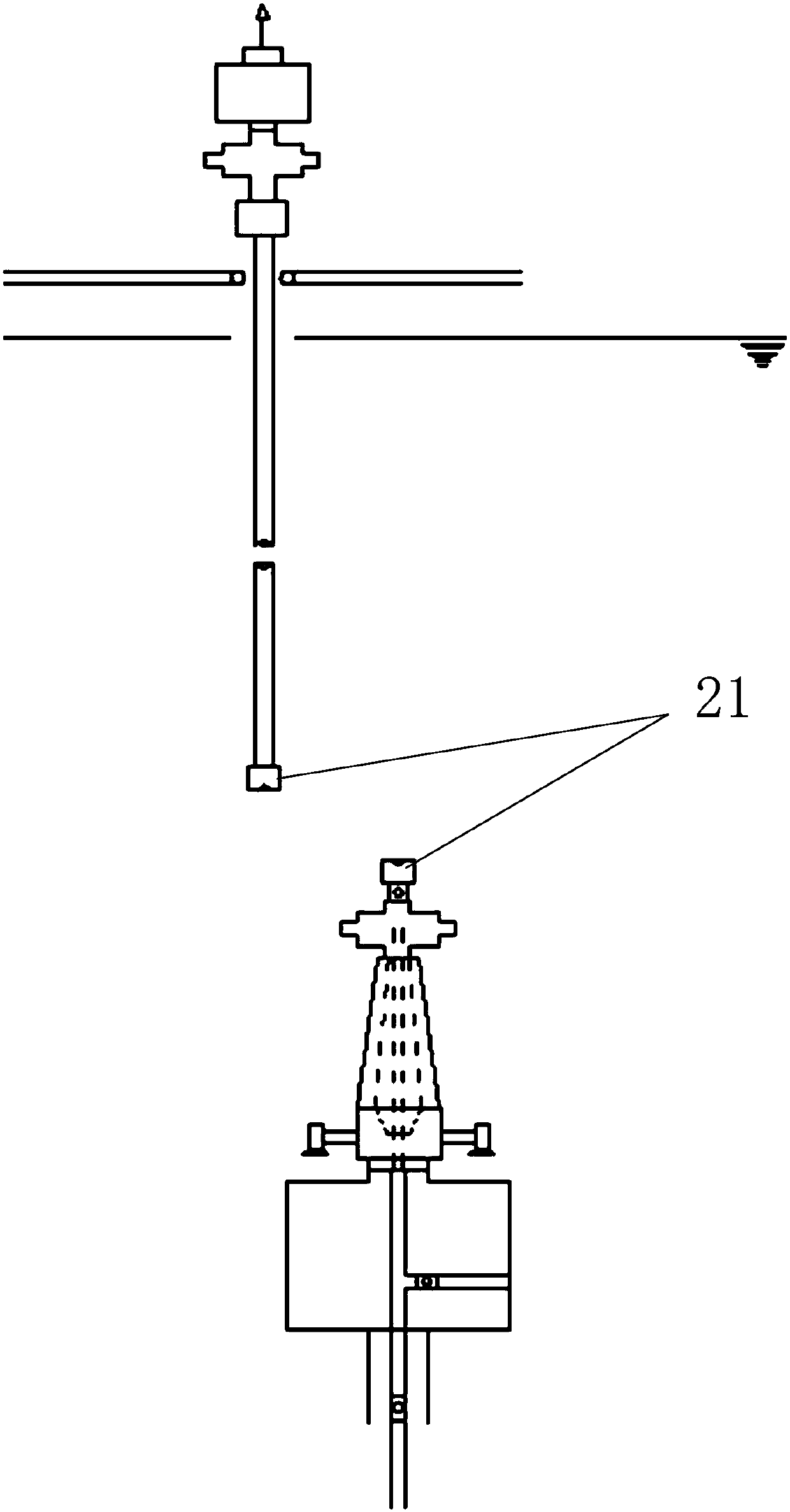

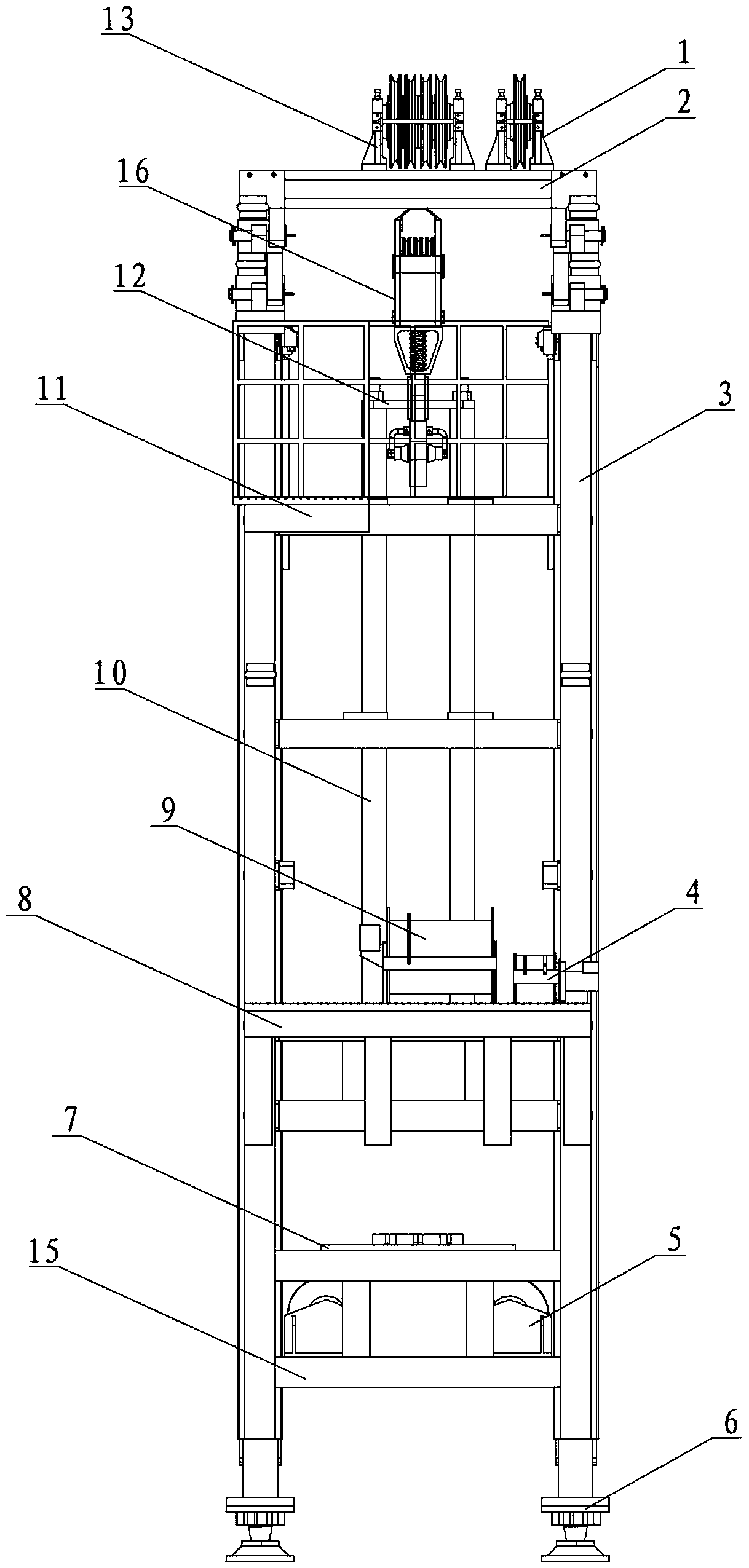

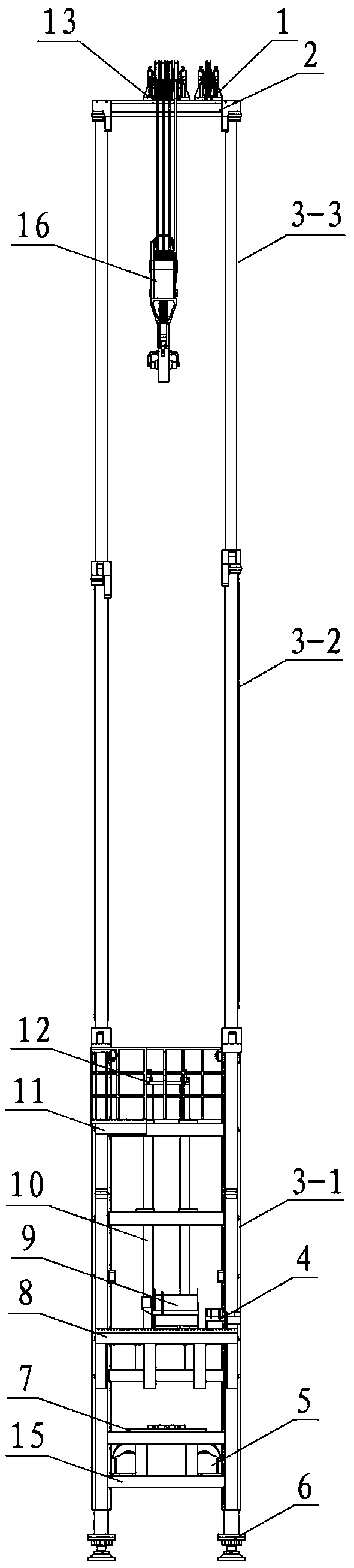

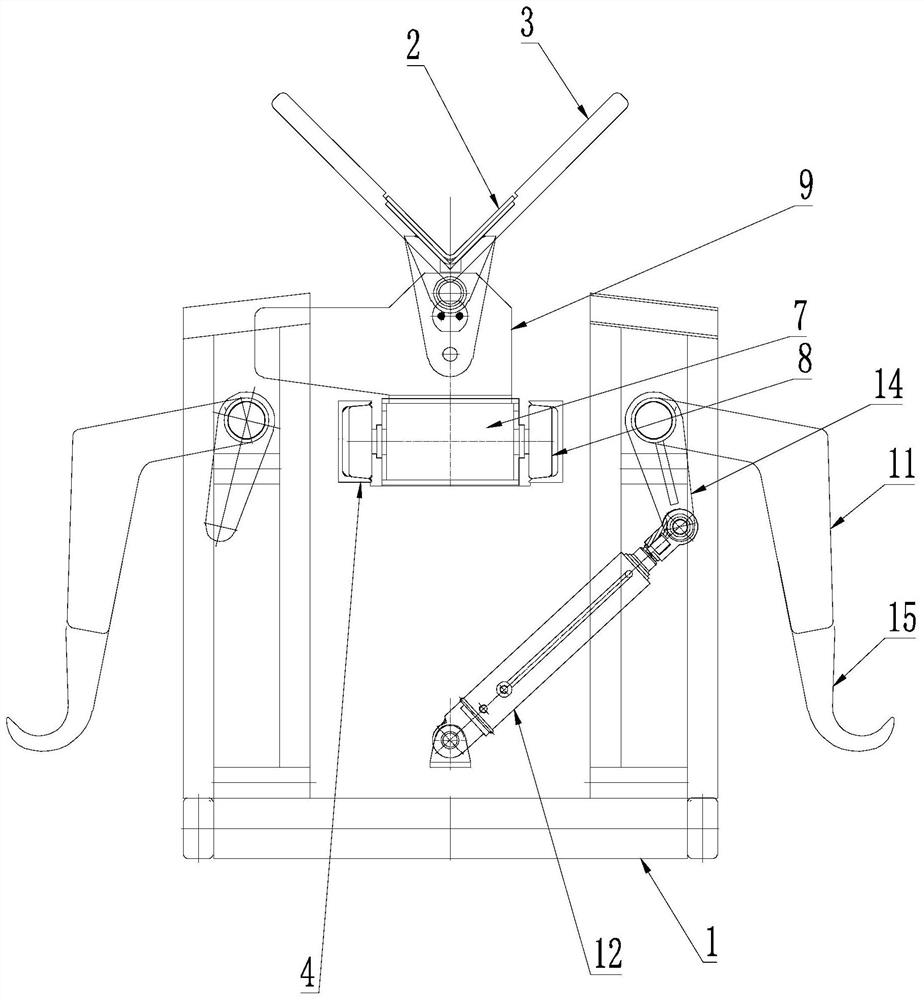

Petroleum workover operation robot

PendingCN108301794ACompact structureSolve the labor-intensiveDrilling rodsDrilling casingsWellheadPetroleum

The invention discloses a petroleum workover operation robot. The petroleum workover operation robot comprises a base device, a righting guiding device, a large arm device, a pendulum seat transmission device, a length measuring device and a hydraulic control system. The hydraulic control system controls the base device, the righting guiding device, the large arm device, the pendulum seat transmission device and the length measuring device to act. Compared with a petroleum workover operation robot in the prior art, the structure is more compact, reasonable and reliable, and the problems that the on-site manual labor intensity is high, the workover efficiency is low, energy consumption is high, and environment pollution is easily caused are solved; and automation of workover operation is achieved. The petroleum workover operation robot is small in occupied area, flexible in wellhead tossing and high in automation degree, and the workover efficiency is greatly improved.

Owner:SENIOR AI EQUIP CO LTD

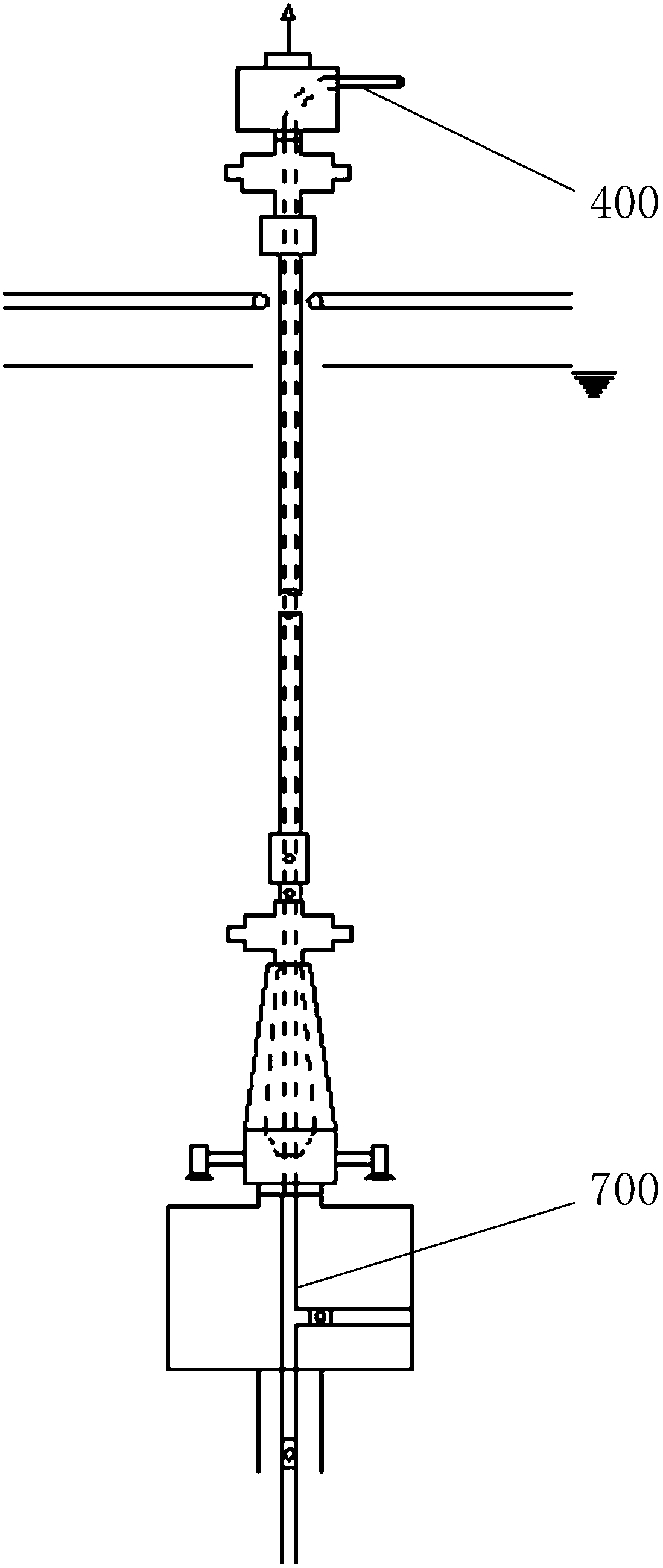

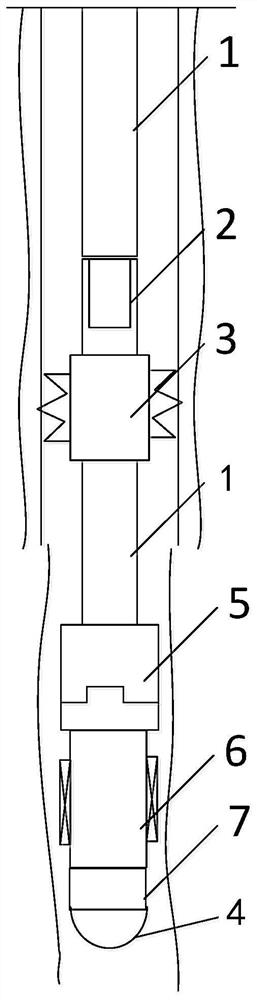

Deepwater oil-gas field light well repairing device and method

ActiveCN107558940AQuick evacuationReliable evacuationDrilling rodsDrilling casingsUnderwaterWell drilling

The invention relates to a deepwater oil-gas field light well repairing device and method. The deepwater oil-gas field light well repairing device comprises an overwater well repairing assembly, a drill pipe and an underwater well repairing assembly, wherein the overwater well repairing assembly can be connected with a crane on an engineering ship, the drill pipe is connected with the overwater well repairing assembly, and the underwater well repairing assembly is connected with the lower end of the drill pipe. The crane has the tension and heave compensation functions, and the underwater wellrepairing assembly comprises a safety joint, a blowout prevention valve, a whole-seal cutter ram blowout preventer, a stress joint, a tie back device and a guiding short circuit which are sequentially connected from top to bottom, wherein the guiding short circuit is arranged in the stress joint; and the underwater well repairing assembly is connected with the lower end of the drill pipe throughthe safety joint, and the tie back device is used for being connected with an underwater Christmas tree. According to the deepwater oil-gas field light well repairing device and method, the well repairing operation of a deepwater oil-gas field can be conducted by adopting the engineering ship, a large-size floating type well drilling platform does not need to be used, the operating cost can be greatly reduced, the well repairing efficiency is improved, and the deepwater oil-gas field light well repairing device and method are suitable for the well repairing operation of an underwater production system of an immovable string.

Owner:CHINA NAT OFFSHORE OIL CORP +1

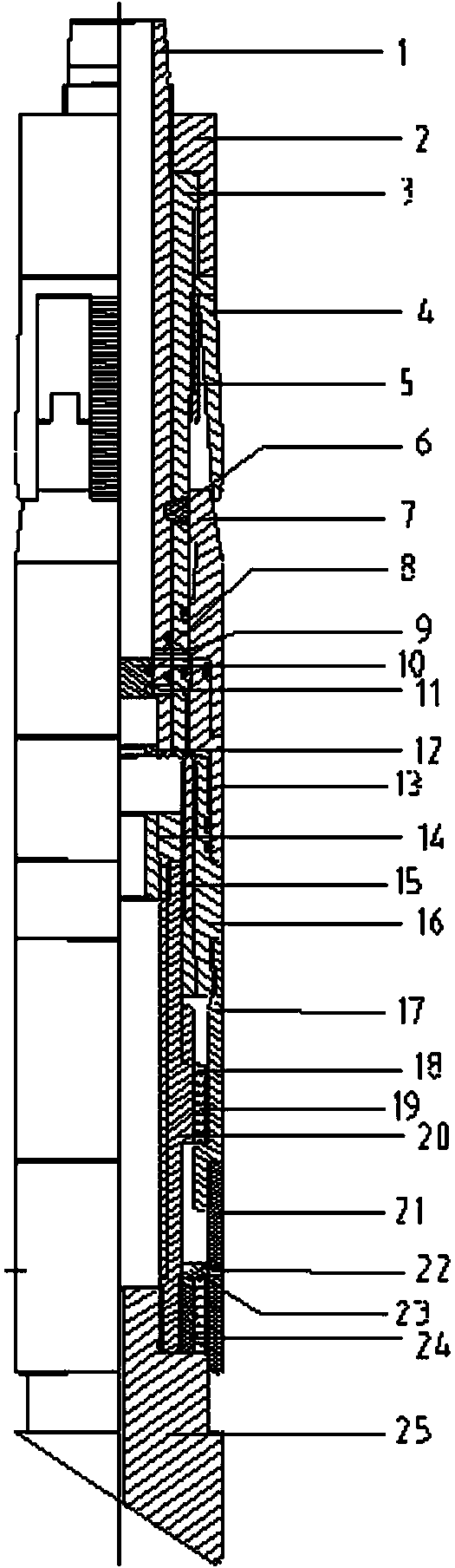

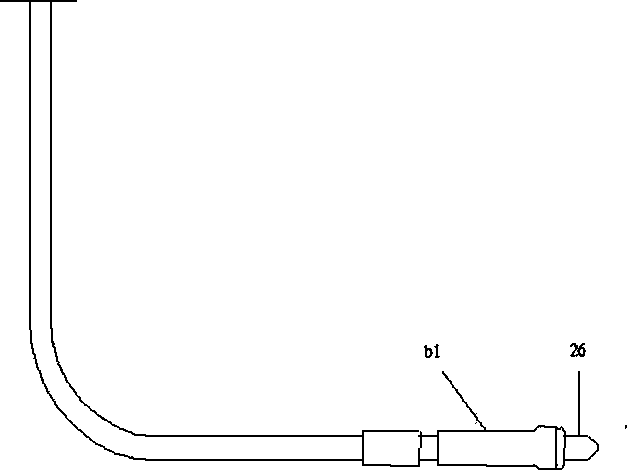

Removable anti-blocking safety valve and special fishing tool for same

InactiveCN102587860ASimple structureEasy to assemble and disassembleWell/borehole valve arrangementsSealing/packingMarine engineeringFishing

The invention relates to petroleum machinery, in particular to a removable anti-blocking safety valve, which comprises a valve body (1) and a valve spool component (2). An anti-blocking cover (5) is arranged at the upper end of the valve spool component (2), an overflow hole (6) is arranged on the wall of the anti-blocking cover (5), and an elastic clamp (7) is sleeved outside the anti-blocking cover (5). A special fishing tool comprises a cable fixing portion (12) at the upper end and an unlocking fishing portion (13) at the lower end. The removable anti-blocking safety valve has the advantages of simple structure and convenience in disassembly and assembly, and can be rapidly removed by the special fishing tool when a downhole goes wrong, so that well repair efficiency is greatly improved, the process of disassembling and drilling for well repair is avoided, and the removable anti-blocking safety valve has a quite high economic significance.

Owner:牡丹江通用石油工具有限公司

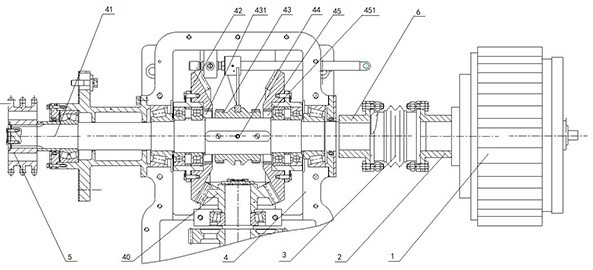

Operation driving device of oil-electricity hybrid power workover rig

InactiveCN112343526ARealize energy saving and environmental protectionImprove workover efficiencyDrilling rodsMachines/enginesPermanent magnet synchronous motorEngineering

The invention relates to the technical field of oil and gas development of oil fields, and discloses an operation driving device of an oil-electricity hybrid power workover rig. The operation drivingdevice comprises a permanent magnet synchronous motor and an angle transmission box, wherein a chain wheel is arranged at the power output end of a power shaft of the angle transmission box; the powershaft is rotationally connected with a bevel gear I and a bevel gear II, and is fixedly connected with a reversing shifting fork in the radial direction; the bevel gear I and the bevel gear II are respectively connected with the reversing shifting fork in a sliding manner in the axial direction of the power shaft, and are connected with a bevel gear III in an engaged manner; an input flange is arranged at the power input end of the power shaft of the angle transmission box; and the input flange is fixedly connected with a coupling, an output flange and the permanent magnet synchronous motor in sequence. Through the operation driving device of the oil-electricity hybrid power workover rig, a vehicle-mounted power system and a permanent magnet synchronous motor power system coexist to perform workover operation; vehicle-mounted power is adopted during migration between well sites; permanent magnet synchronous motor power is adopted during light-load workover operation; and hybrid powerof the vehicle-mounted power and the permanent magnet synchronous motor power is adopted during heavy-load workover operation, so that the energy conservation and the environmental protection are realized, and the workover operation efficiency is improved.

Owner:山东创新石油技术有限公司 +1

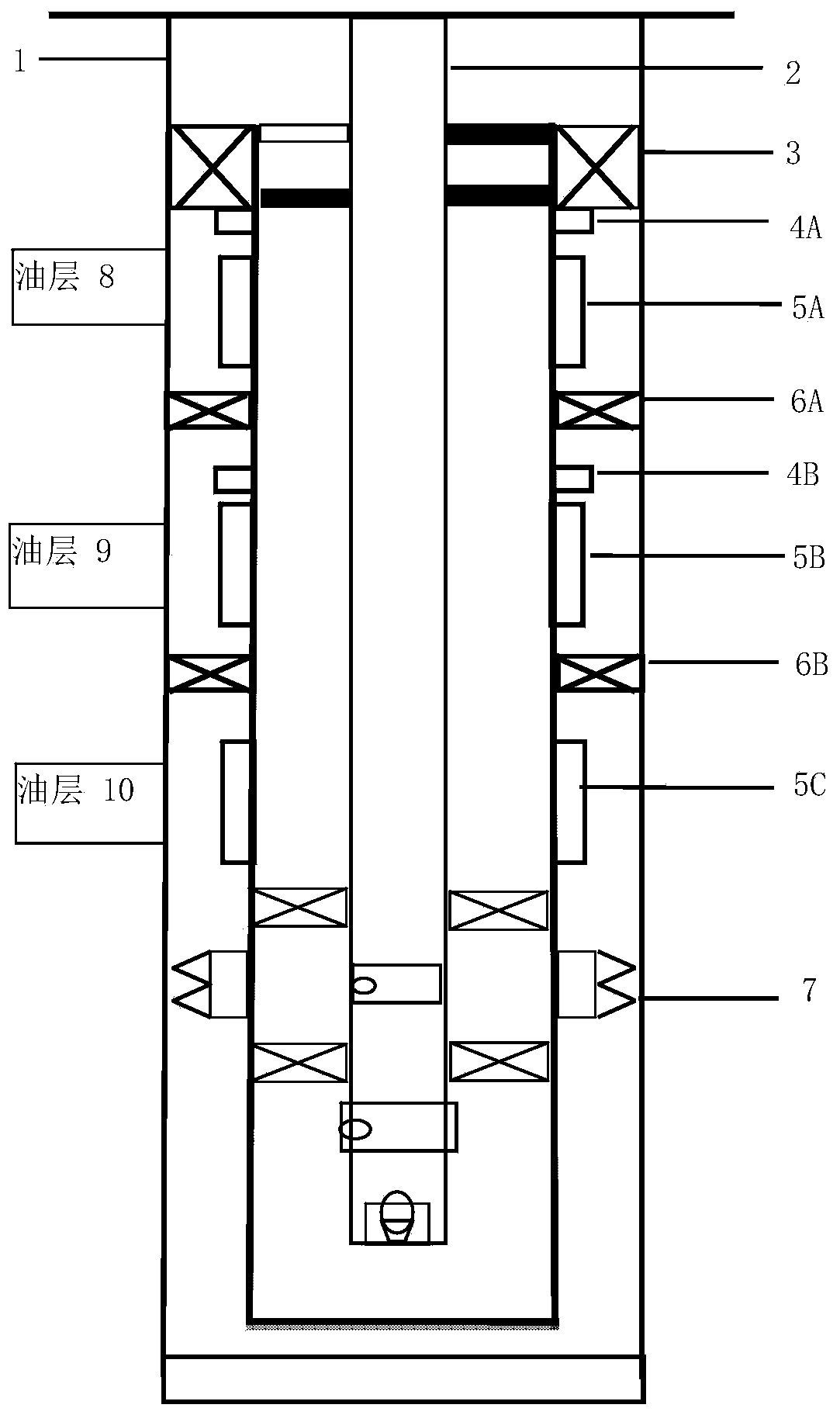

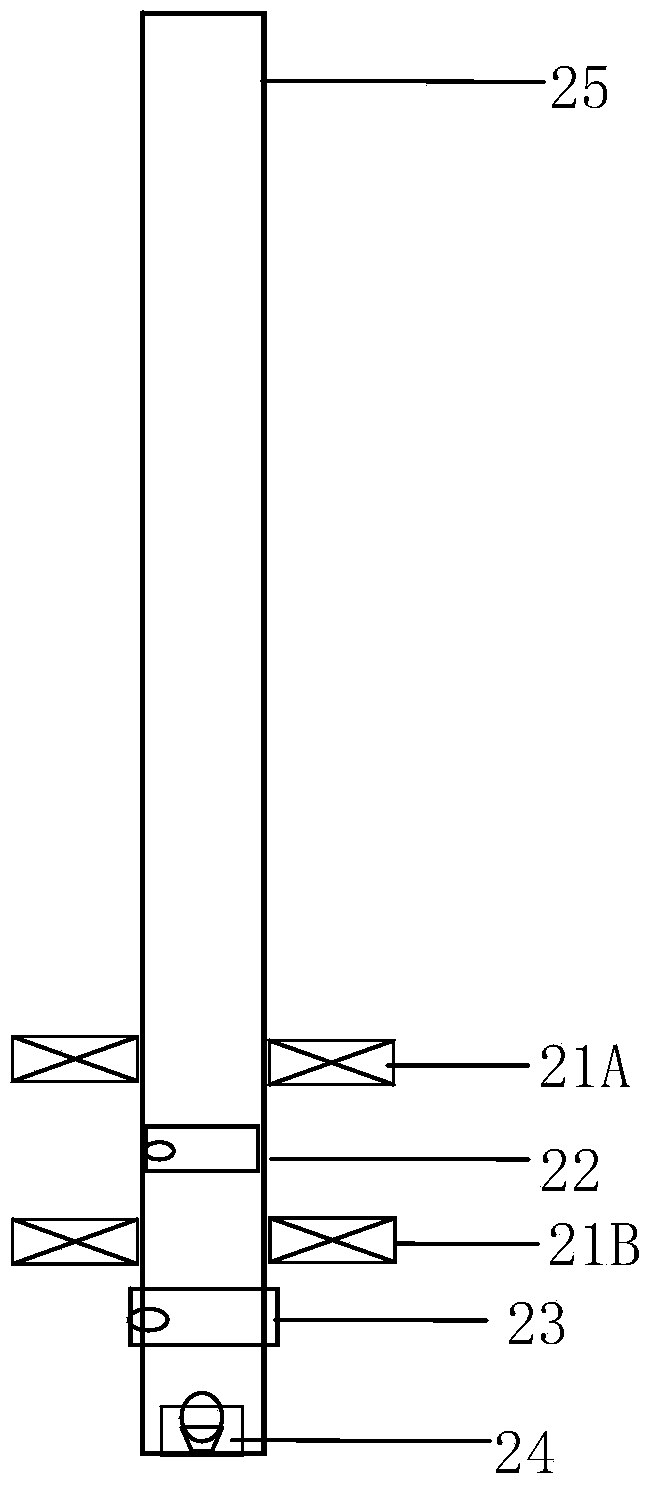

Multi-stage and layered sand control completion device and method for one trip string

InactiveCN102808594BUnlimited number of levelsConsistent inner diameterFluid removalSealing/packingPetroleum engineering

The invention discloses a device and a method for multi-stage layering sand prevention and well completion by one-step pipe column. The device comprises an oil-string casing inserted into a first oil layer, a second oil layer and a third oil layer in sequence, wherein a blind pipe is arranged in the oil-string casing; a pipe column which integrates setting seal and examining seal is arranged inside the blind pipe; release suspension packers, first safety connectors, first sand prevention pipe columns, first isolation packers, second safety connectors, second sand prevention pipe columns, second isolation packers, third sand prevention pipe columns and supporting slips are arranged on the outer side of the blind pipe from the top down in a sleeving way; the upper part of the pipe column which integrates the setting seal and the examining seal is connected with a standard oil pipe; the lower part thereof and the release suspension packers are integrally connected to be a whole; the first sand prevention pipe columns are aligned to the first oil layer; the second sand prevention pipe columns are aligned to the second oil layer; the third sand prevention pipe columns are aligned to the third oil layer; and the supporting slips are mounted at the lower end of the blind pipe and positioned below the third oil layer. According to the invention, the number of layered stages is not limited, so that the setting seal and examining seal operations can be performed at the same time, thereby guaranteeing the seal effect of the packers in all stages and improving the well repairing efficiency.

Owner:CNOOC ENERGY TECH & SERVICES

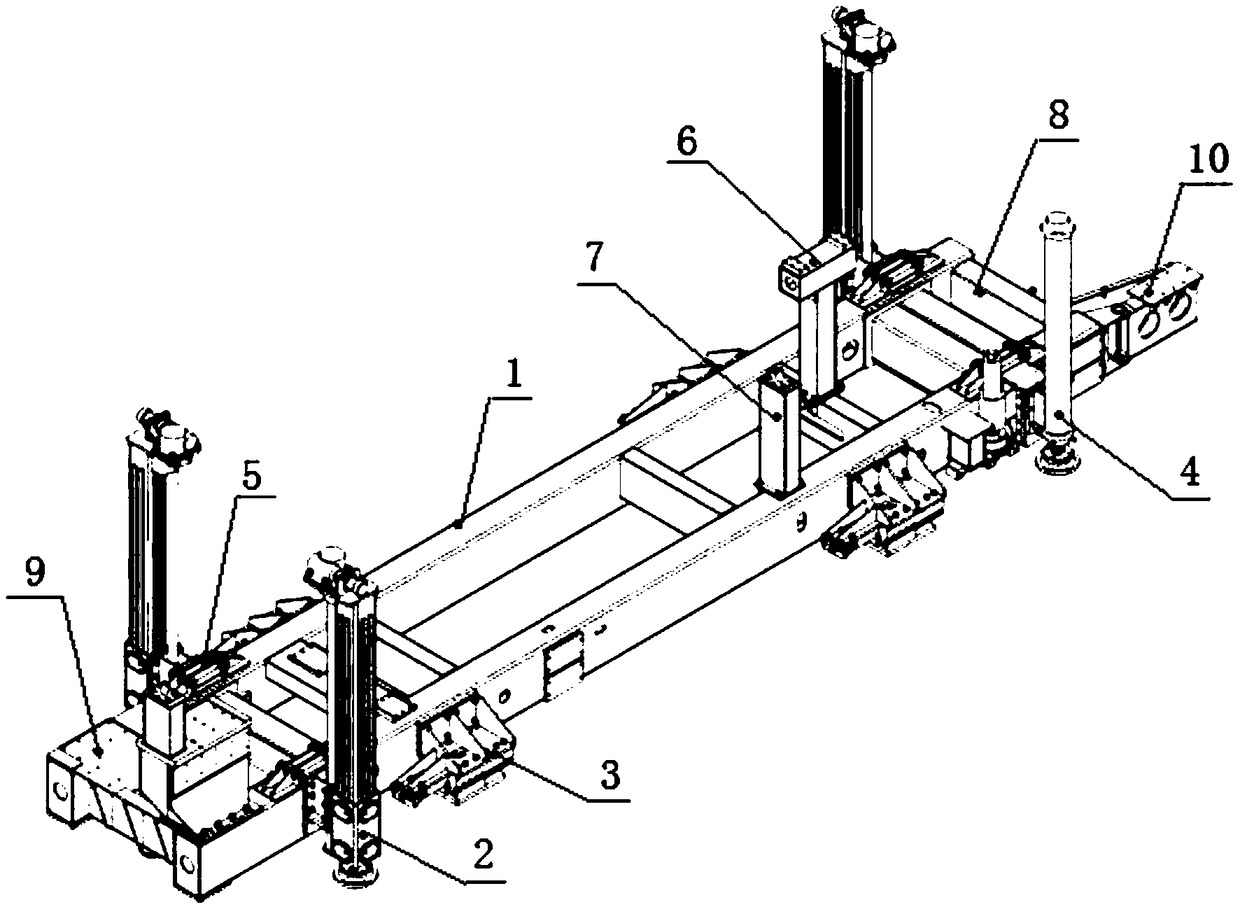

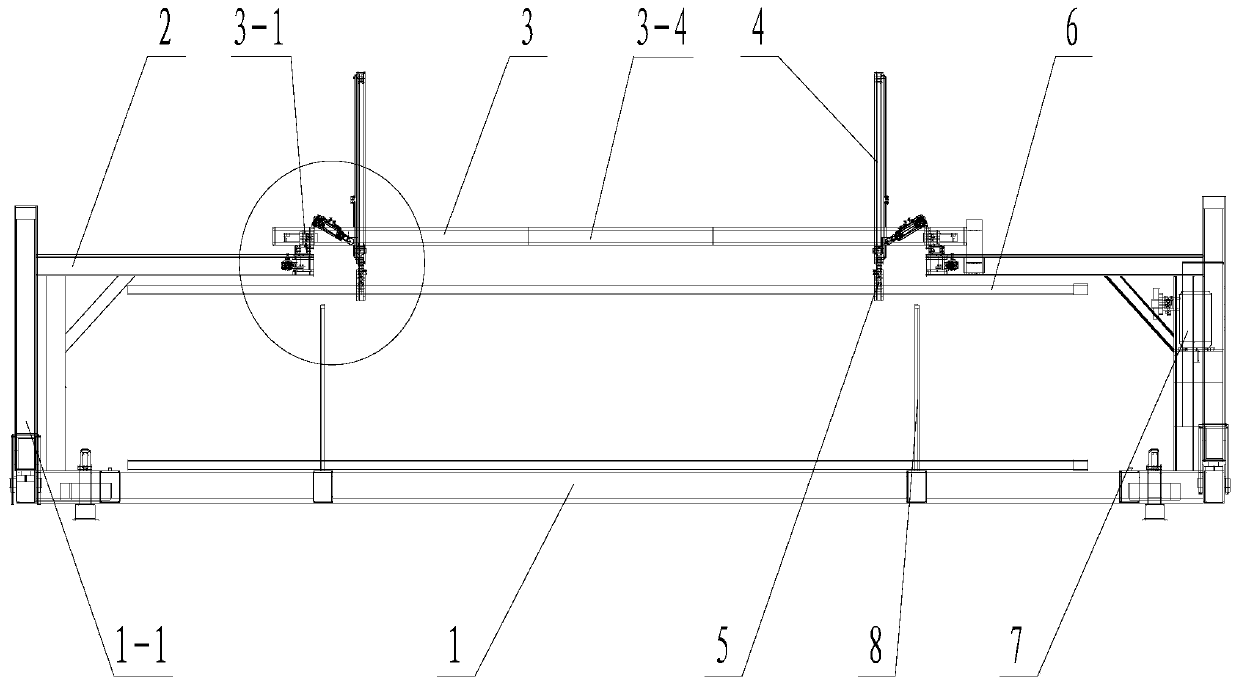

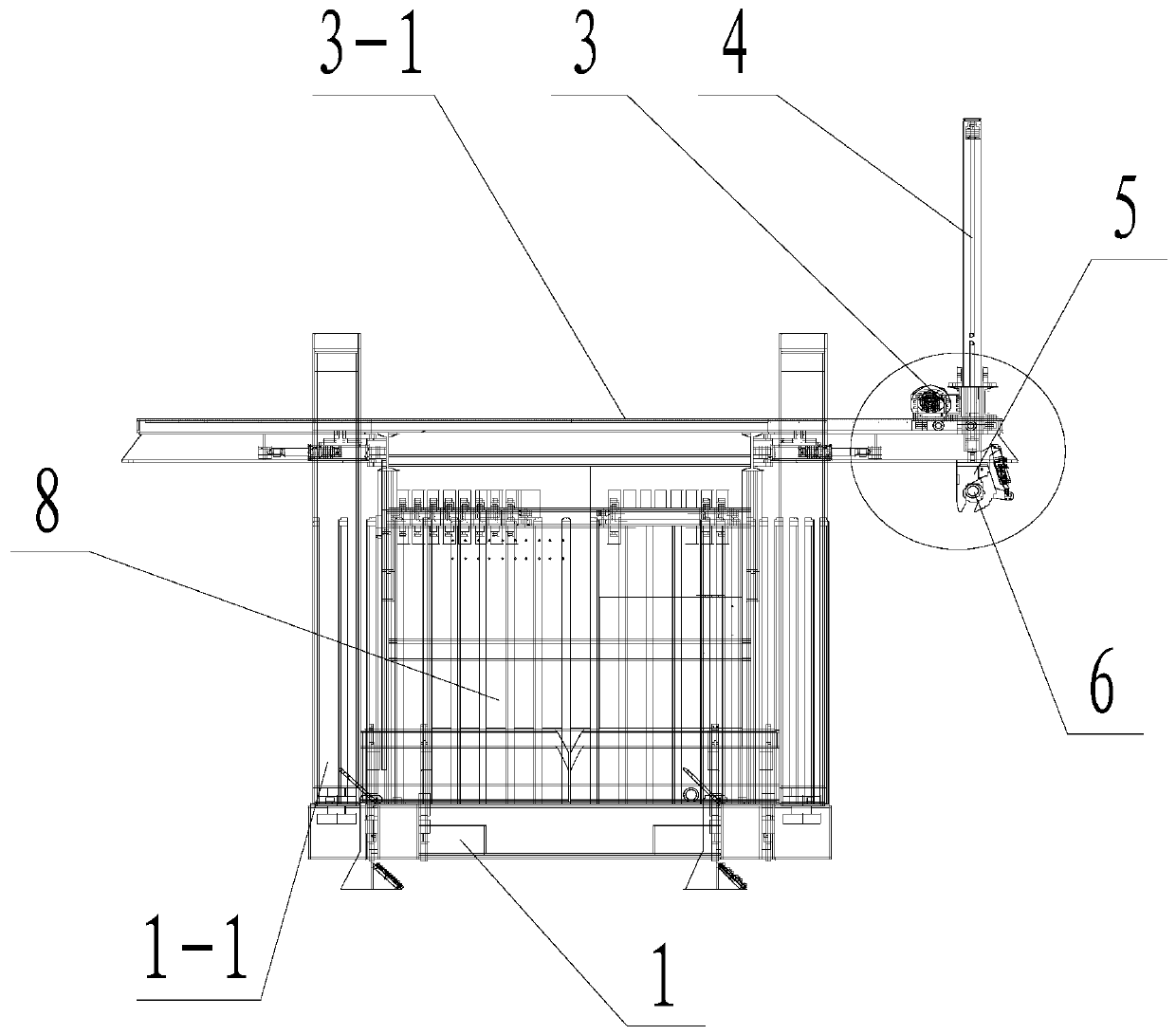

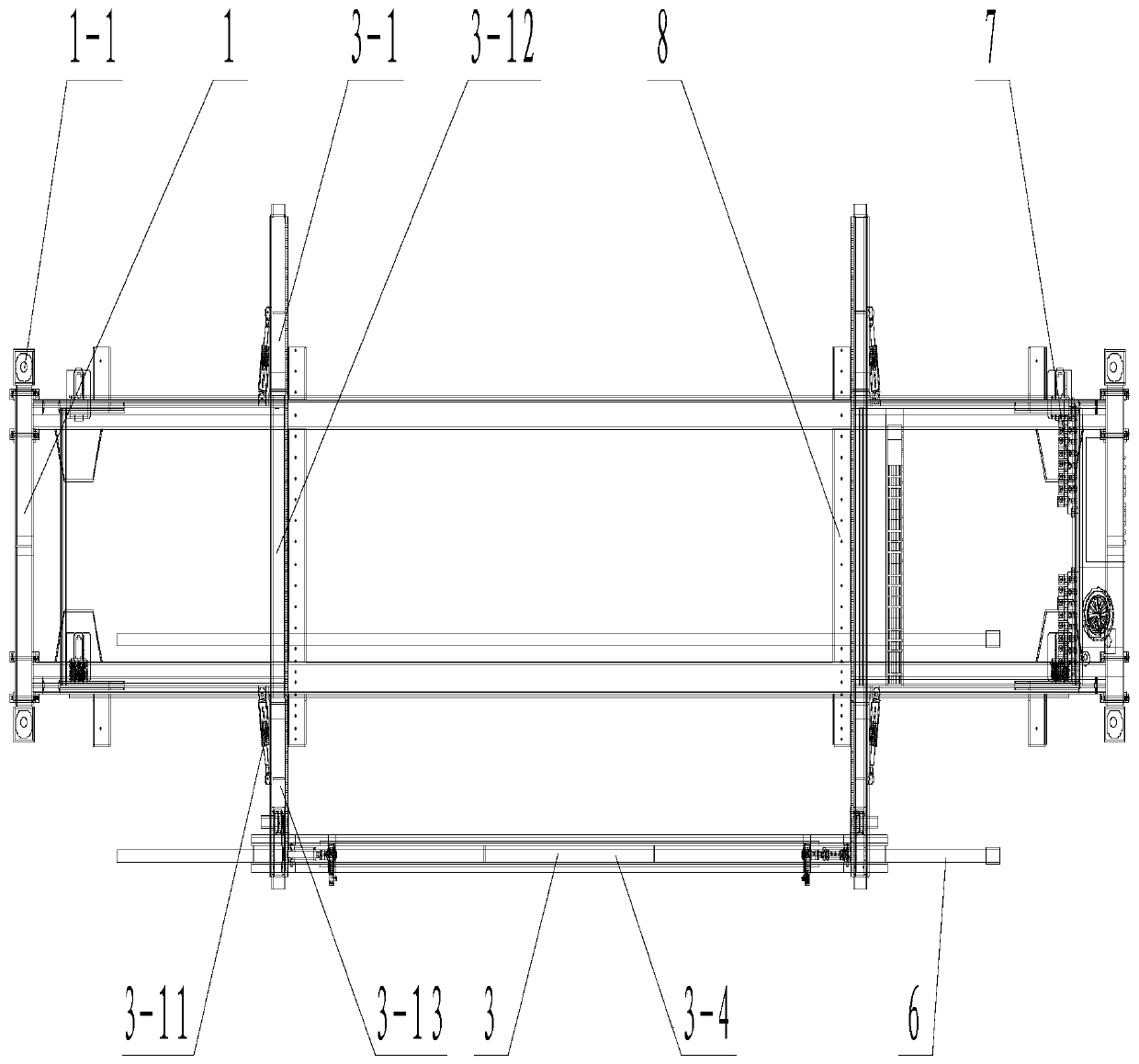

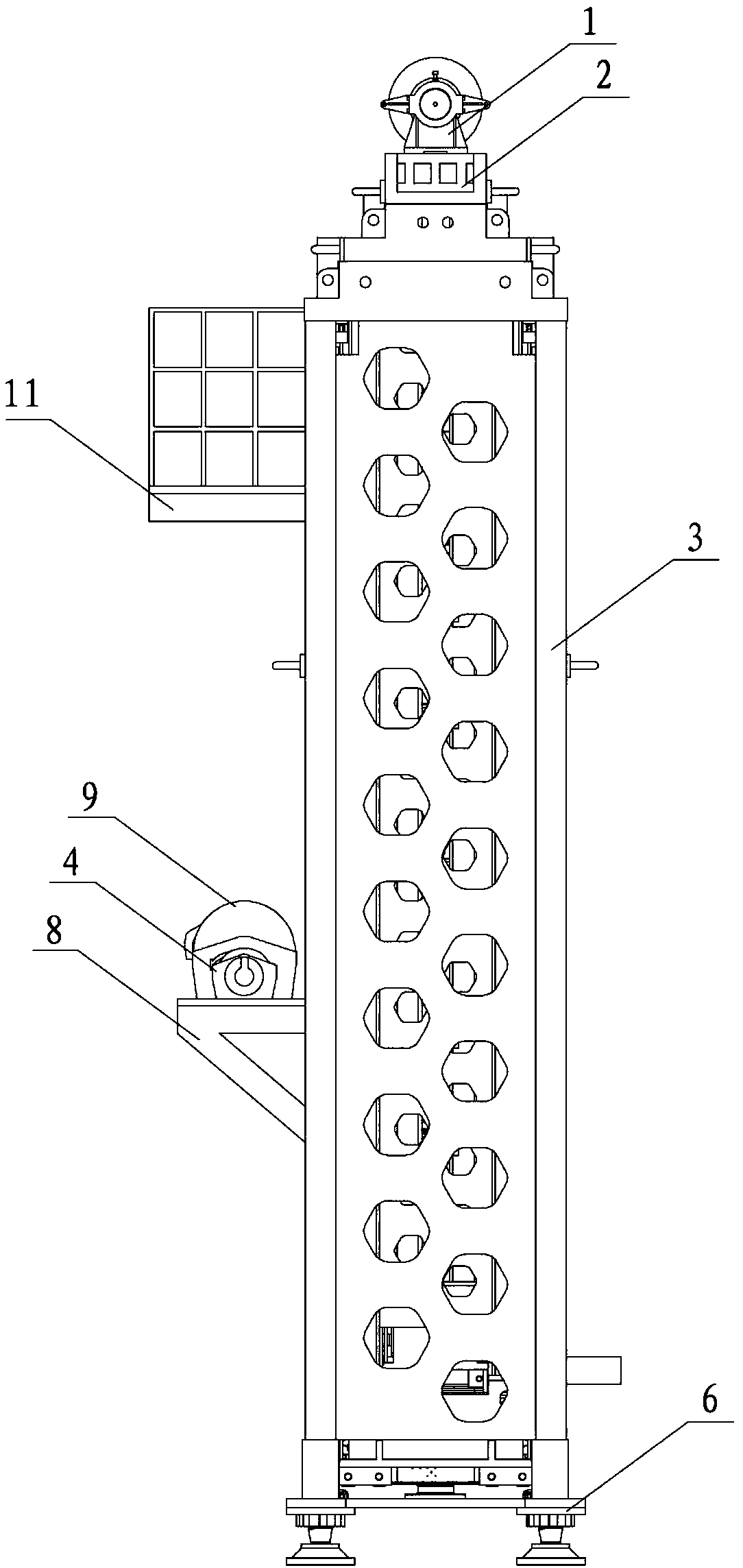

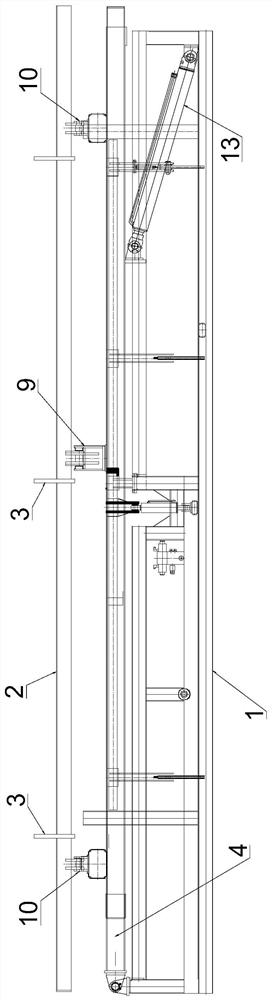

Pipe rod storage device for oil field workover operation

ActiveCN109850560AReduce labor intensityImprove workover efficiencyControl devices for conveyorsEngineeringDrive motor

The invention relates to the technical field of oil field exploitation, in particular to a pipe rod storage device for oil field workover operation. The pipe rod storage device comprises a base, a bracket located at the left and right ends of the base, a pipe rod blocking member fixedly arranged on the base, a horizontal moving mechanism, a vertical moving mechanism, a clamping mechanism, a detecting mechanism and a control mechanism; the horizontal moving mechanism comprises a guide rail member arranged on the bracket and extending in the front and rear direction of the base, a support wheelrotationally arranged on a moving frame and supported by the guide rail member and a driving motor arranged on the moving frame and used for driving the support wheel to rotate; the vertical moving mechanism is arranged on the moving frame and can move up and down; the clamping mechanism is arranged at the lower end of the vertical moving mechanism and used for clamping a pipe rod; the detecting mechanism is arranged on the bracket and used for detecting the length of the pipe rod clamped by the clamping mechanism; and the control mechanism is arranged on the bracket and used for controlling the horizontal moving mechanism, the vertical moving mechanism, the clamping mechanism and the detecting mechanism to move.

Owner:PETROCHINA CO LTD

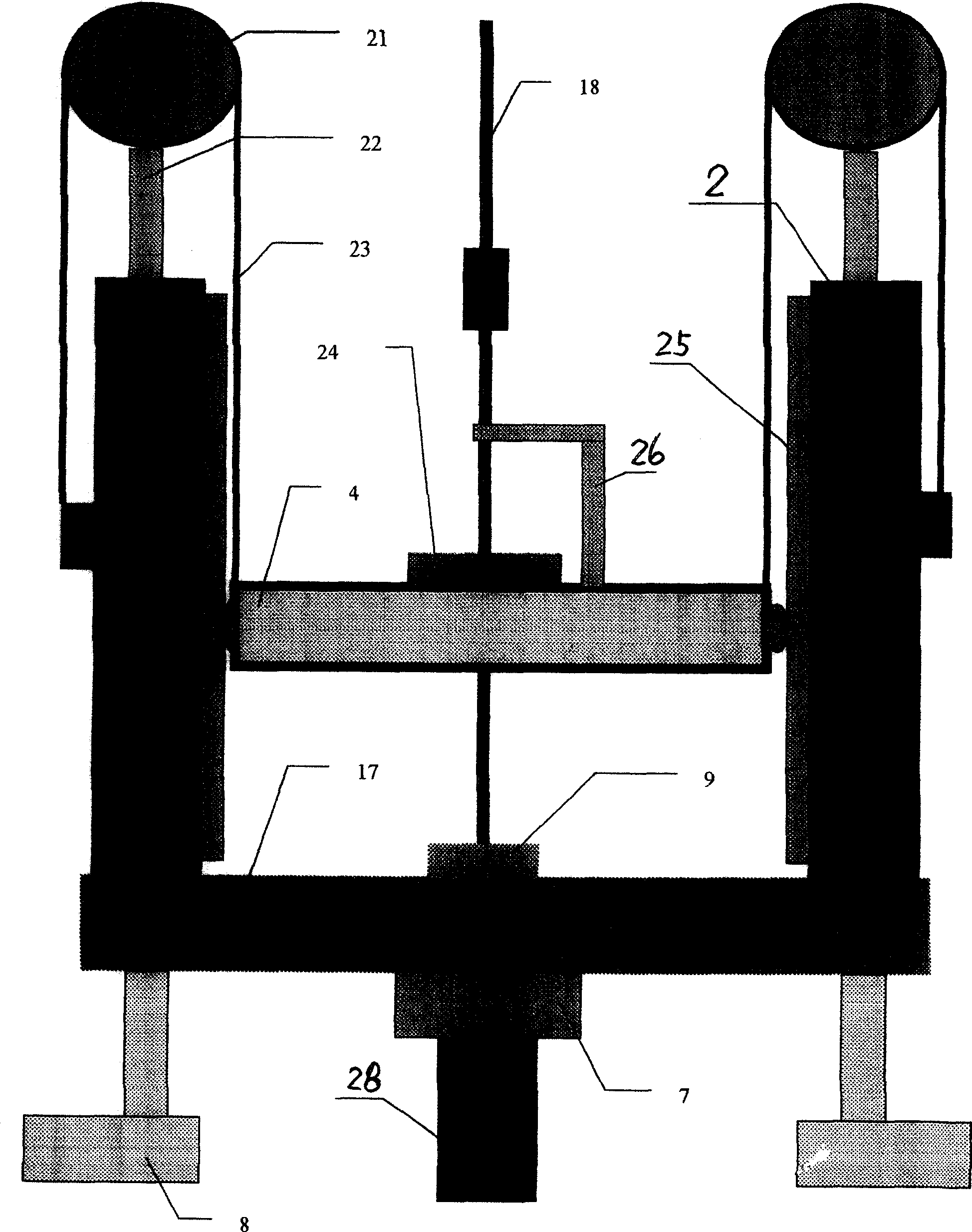

Hydraulic hoisting device for replacing pipe column and wellhead part and method thereof

PendingCN106939775AImprove work efficiencyEffectively provide work efficiencyBorehole/well accessoriesMechanical engineeringHoist device

The invention discloses a hydraulic hoisting device for replacing a pipe column and a wellhead part. The hydraulic hoisting device is provided with a hoisting system and a connecting mechanism, wherein the hoisting system is connected with a wellhead device to be replaced through the connecting mechanism; the hydraulic hoisting device further comprises a pipe column locking device which is mainly used for locking a downhole pipe column connected with the wellhead device; a method comprises the following steps: 1) mounting the hoisting system; 2) detaching the wellhead device; 3) assembling a wellhead four-way joint. By adopting the hydraulic hoisting device for replacing the pipe column and the wellhead part, wellhead replacement is carried out, and a pipe arrangement step is saved; the downhole pipe column only needs to be partially lifted, and then the downhole pipe column is locked by utilizing the matched pipe column locking device; then the whole weight of the downhole pipe column is transferred to an outer pipe, so that a wellhead can be replaced under the condition that the whole downhole pipe column is not detached, and furthermore, the working efficiency of wellhead maintenance work is effectively improved, and the maintenance time is reduced; the time consumption in a replacement process is only no more than 25 percent that of the prior art.

Owner:梅宗禄

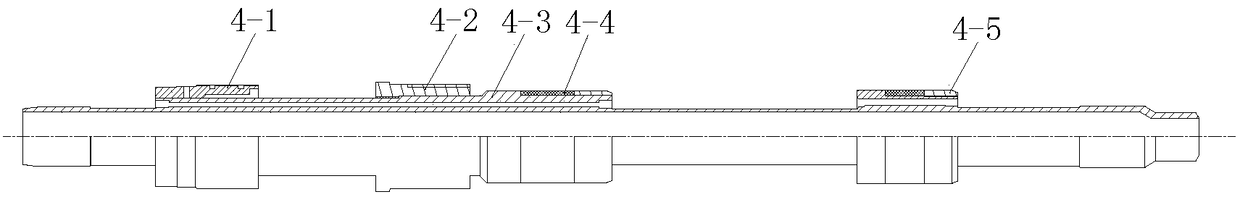

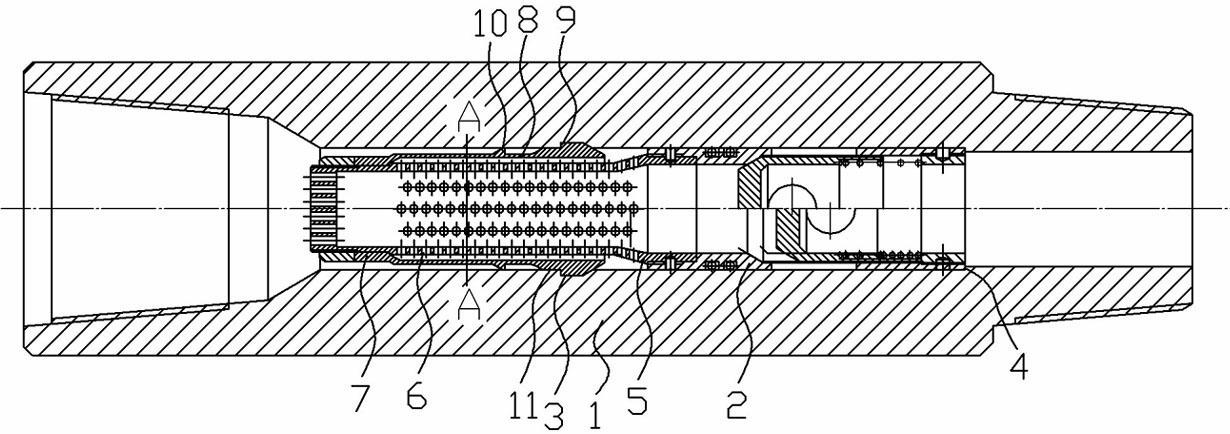

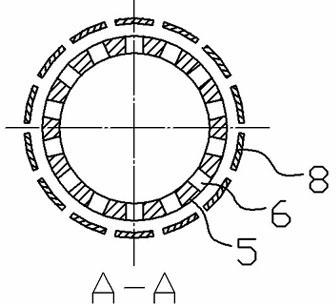

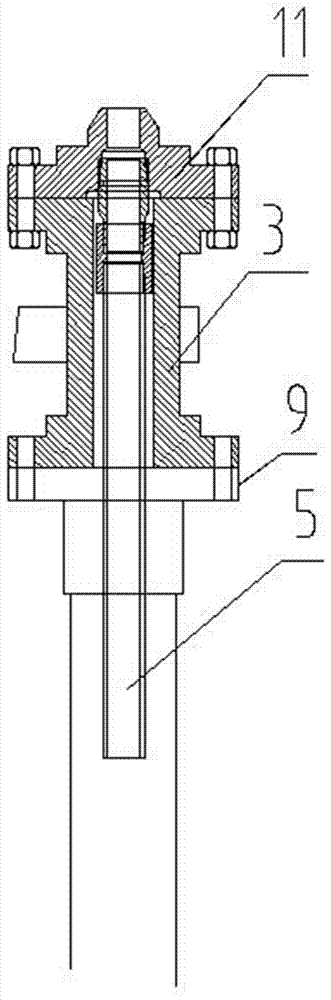

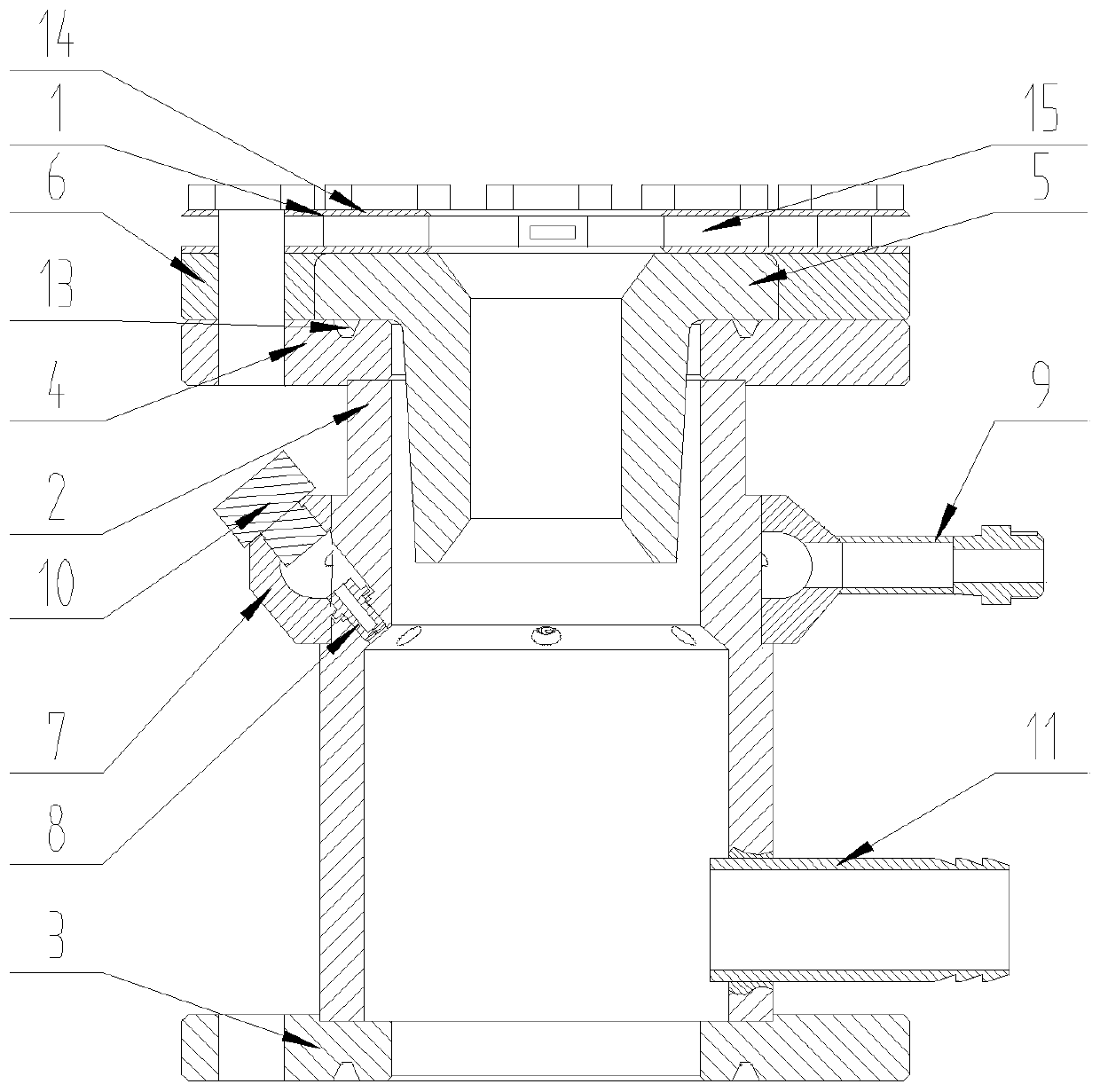

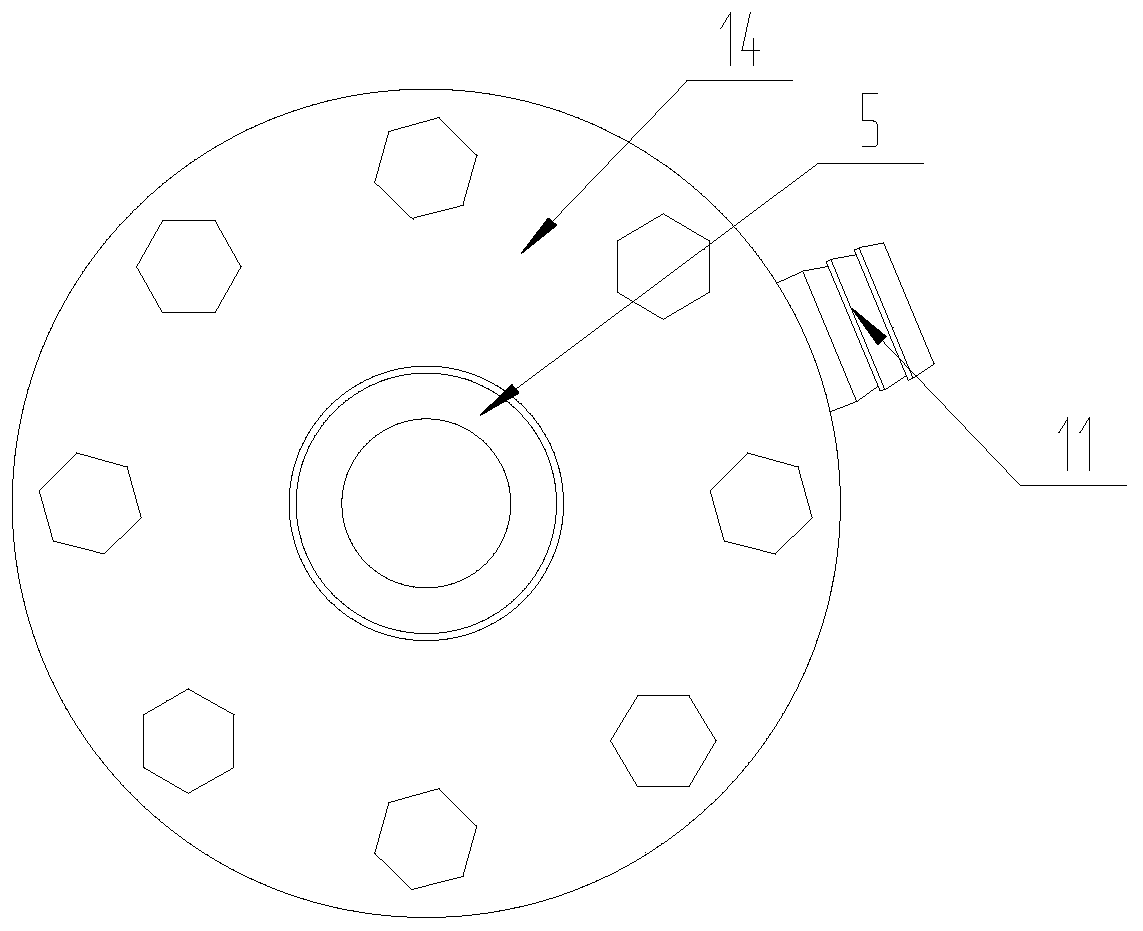

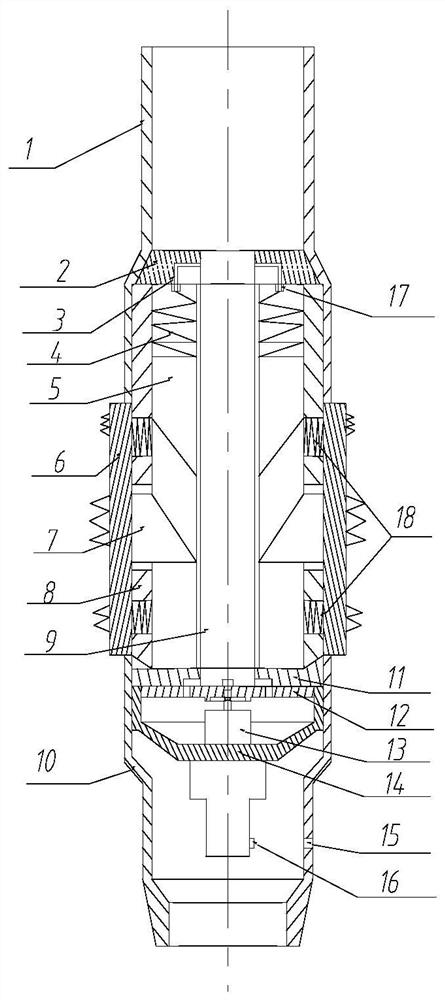

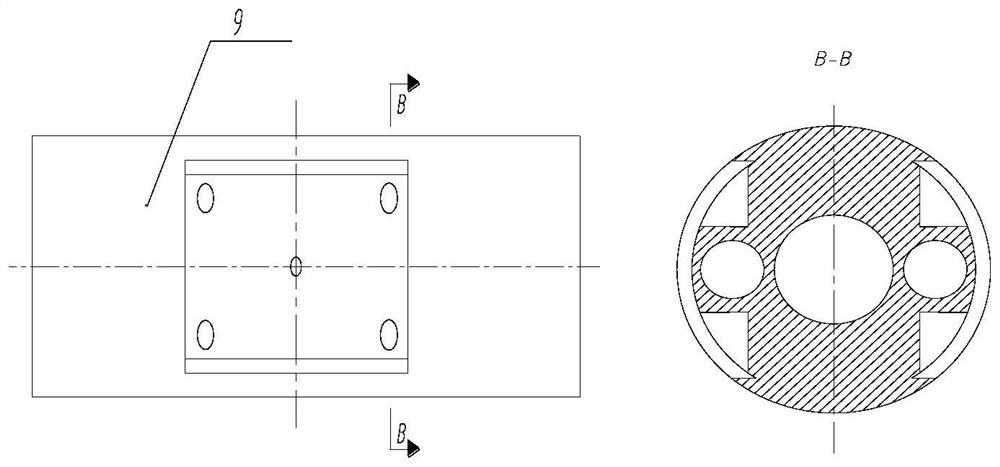

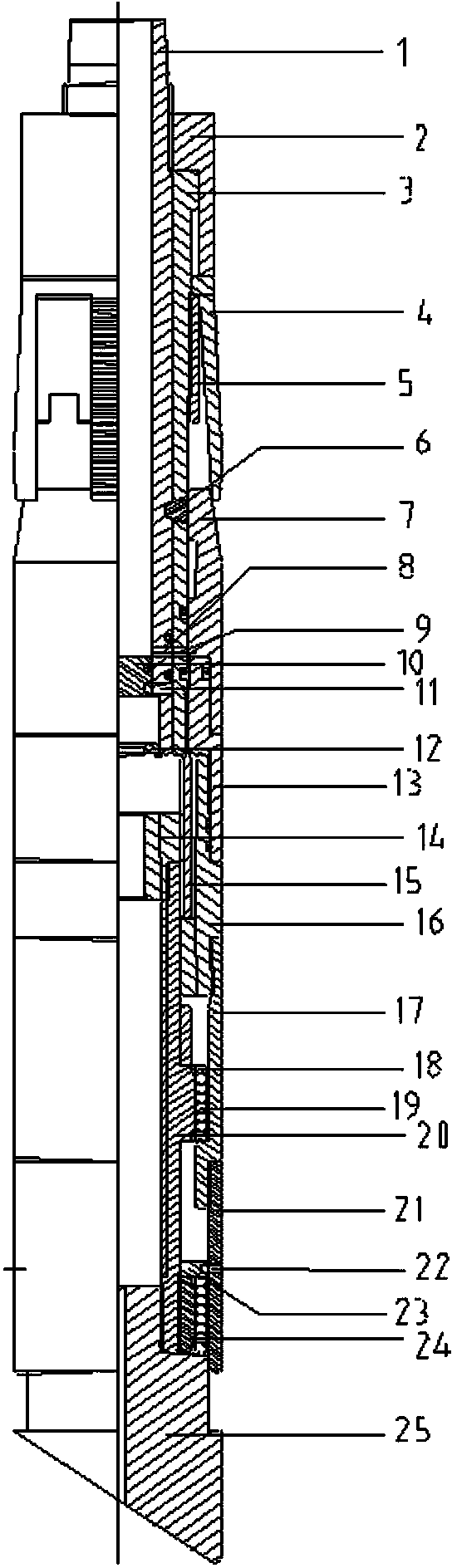

Oil pipe online cleaning and flaw detection device

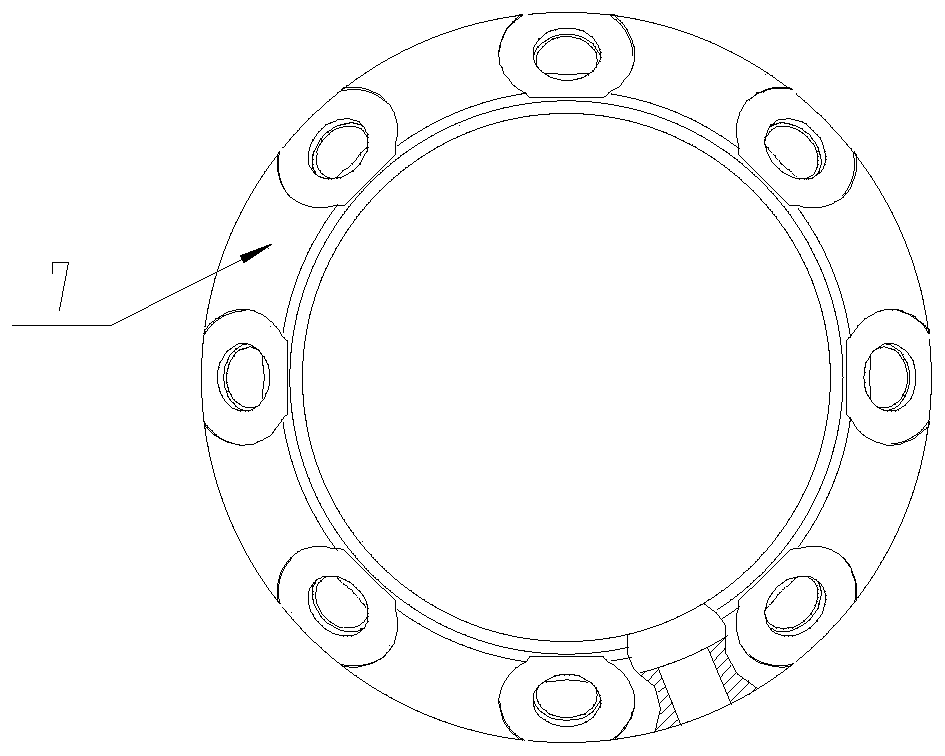

PendingCN110173224AGuaranteed cleanlinessAvoid pollutionSurveyCleaning apparatusWorking environmentFlange

The invention relates to the field of oil pipe flaw detection, in particular to an oil pipe online cleaning and flaw detection device. The oil pipe online cleaning and flaw detection device comprisesa probe, a lower flange, a housing, a cleaning device, an upper flange and a self-sealing rubber core; the housing is of a cylinder hollow structure; the upper flange is fixed to the top end of the housing; the lower flange is fixed to the bottom end of the housing; the upper flange and the lower flange are coaxial with the housing; the cleaning device is fixed to the outer circumferential surfaceof the housing; nozzle through holes communicating with the cleaning device are formed in the inner circumferential surface of the housing; the execution end of the cleaning device is positioned in the nozzle through holes; the top end of the upper flange is detachably connected with a gasket; the self-sealing rubber core is detachably connected in the gasket; and one end of the self-sealing rubber core passes through the upper flange and extends into the housing. The automatic cleaning and flaw detection of an oil pipe in the oil pipe lifting process can be achieved, the operation is convenient, the cleanliness of a working environment is ensured, the pollution to a surrounding environment is avoided, the working environment of the construction personnel is improved, the construction procedures are reduced, and the workover operation efficiency is effectively improved.

Owner:PETROCHINA CO LTD

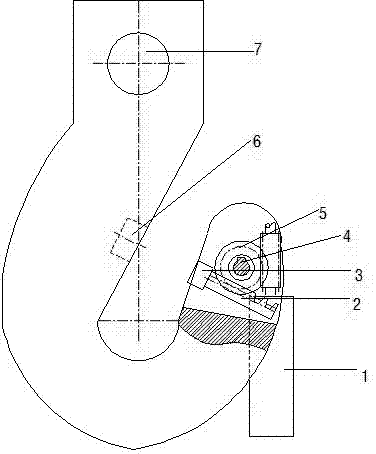

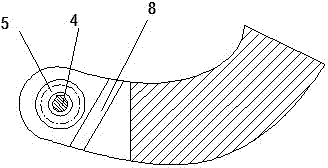

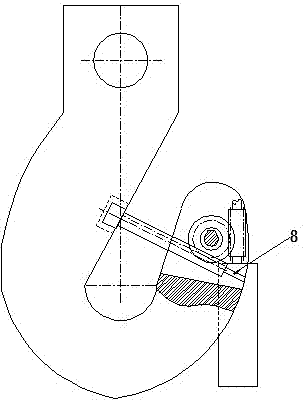

Intelligent large hook for mechanical workover operation

Disclosed is an intelligent large hook for mechanical workover operation. The intelligent large hook for mechanical workover operation comprises a hook body and an automatic locking mechanism. The automatic locking mechanism is arranged on a hook tip at the position of an inlet of the hook body, and comprises a rack and a rack extension driving mechanism, wherein a guide device which guarantees the movement trail of the rack is further arranged on the two sides of the rack. The rack extension driving mechanism comprises a motor, a worm wheel and a worm, wherein the motor is connected with the worm wheel through the worm, the worm wheel sleeves a mandrel, and the worm wheel and the rack are in meshing connection. The guide device comprises hinge pins and rack movement tracks, wherein the hinge pins are installed on the two sides of the rear end of the rack, the rack movement tracks are formed inside the hook tip on the two sides of the rack, and the rack performs front-and-rear linear movement along the rack movement tracks through the hinge pins. According to the invention, a lifting ring and a lifting clamp do not need to be manually taken down or be righted, mechanical workover operation without operators on a wellhead is achieved, the work intensity of workers is reduced, the wellhead axis time is not occupied by operation, and then the efficiency of mechanical workover operation is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

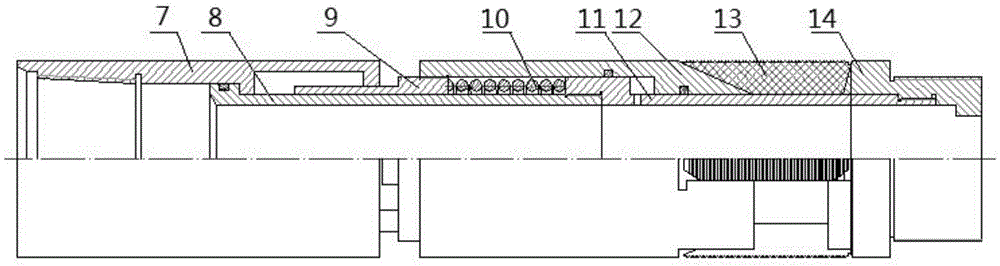

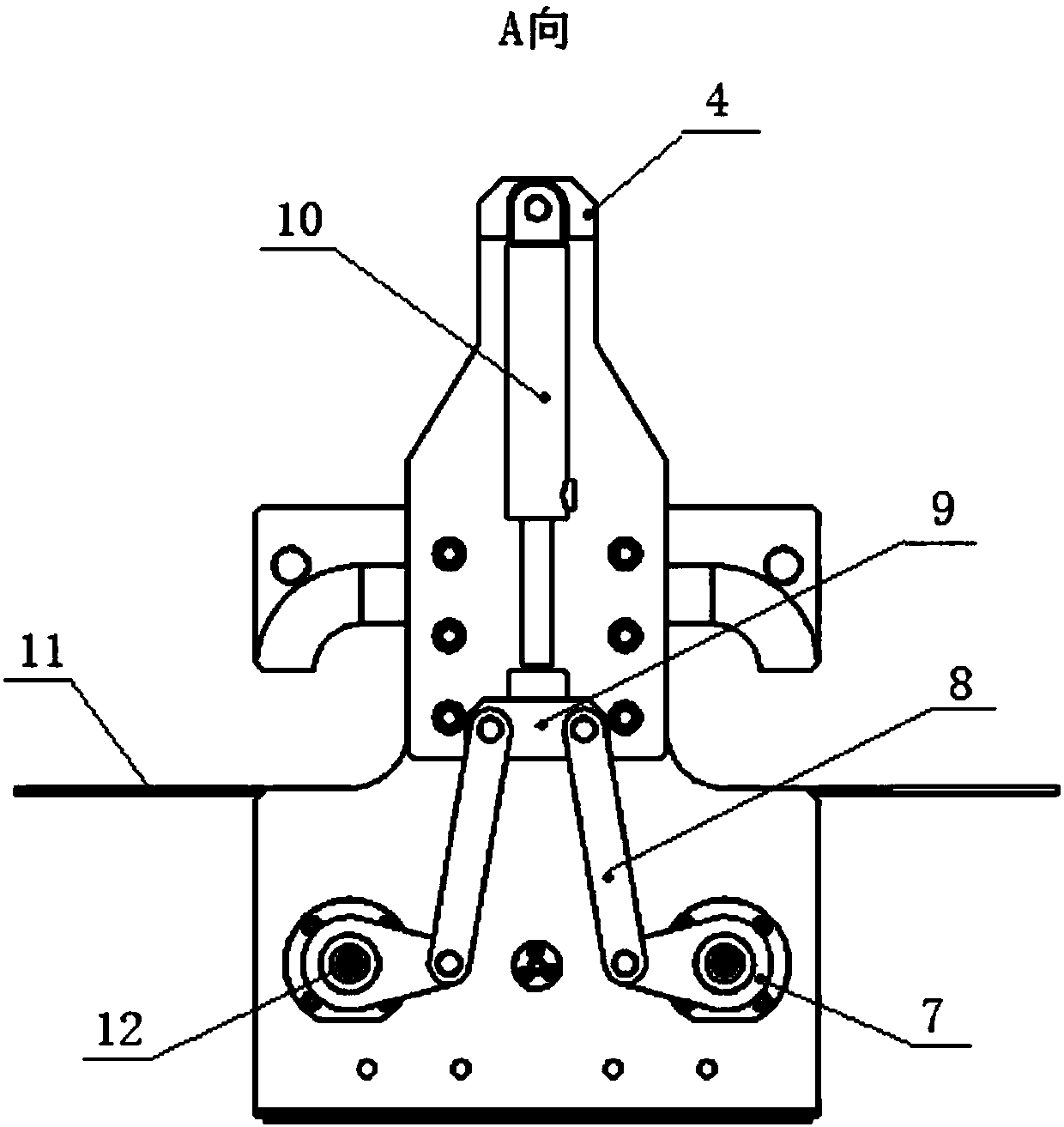

Automatic hydraulic elevator device

PendingCN107939312AFully automatedLabor savingDrilling rodsDrilling casingsHydraulic cylinderEngineering

The invention discloses an automatic hydraulic elevator device. The automatic hydraulic elevator device comprises an elevator main body, two swing seats, two clamping sleeves, a connecting plate, an upper supporting frame, a lower supporting frame and a hydraulic cylinder. A cavity is formed in the middle of the elevator main body; the two swing seats are connected in the cavity of the elevator main body through swing seat shafts; the swing seats and the swing seat shafts are positioned through flat keys, and the swing seats can rotate along with the swing seat shafts; the two clamping sleevesare fixed to the swing seats and can swing along with the swing seats; the upper supporting frame and the lower supporting frame are mounted at one end of the elevator main body, and the connecting plate is mounted at the other end of the elevator main body; the hydraulic cylinder is fixed to the connecting plate, and a hydraulic rod of the hydraulic cylinder is connected with a connecting rod mechanism; the end of the connecting rod mechanism is connected with the swing seat shafts through keys, and the hydraulic cylinder drives the connecting rod mechanism to rotate; and opening and closingof the clamping sleeves are driven through the swing seat shafts. The automatic hydraulic elevator device has the beneficial effects that automatic elevating of an oil pipe is achieved, so that laborforce is saved, the well repairing efficiency is improved, the cost is saved, and automation of an oil pipe elevator is achieved.

Owner:SENIOR AI EQUIP CO LTD

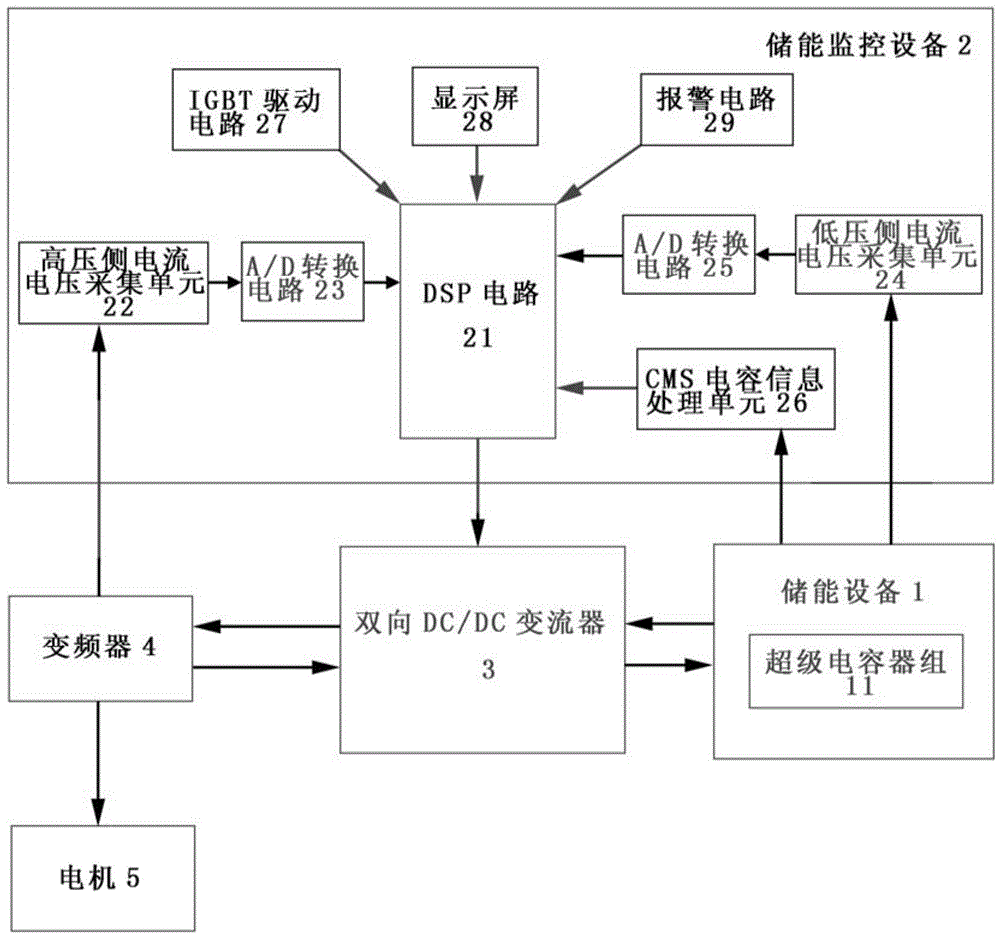

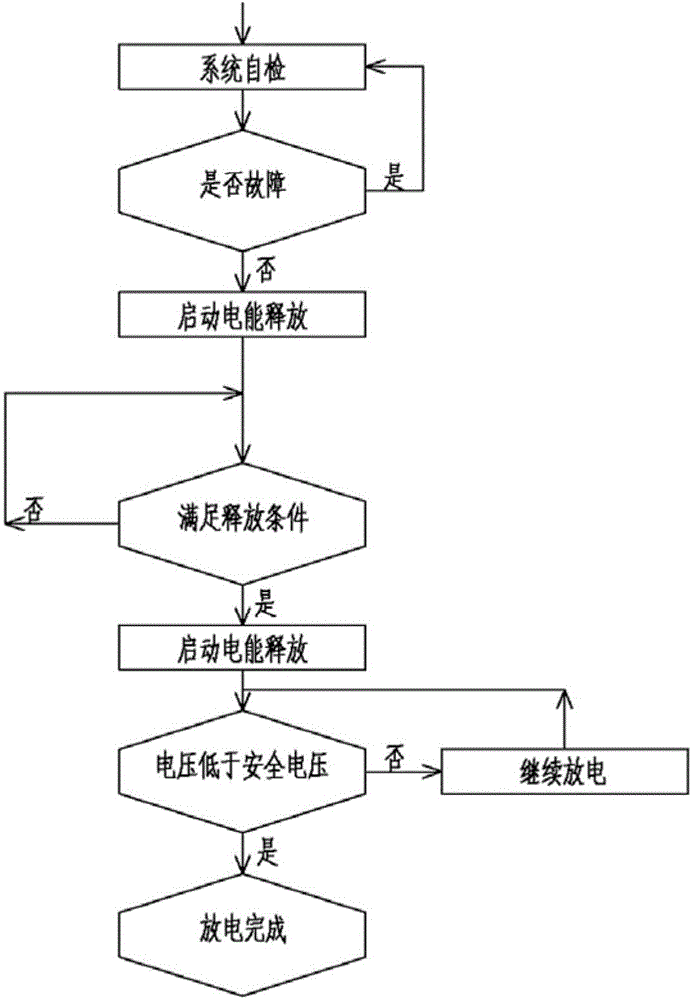

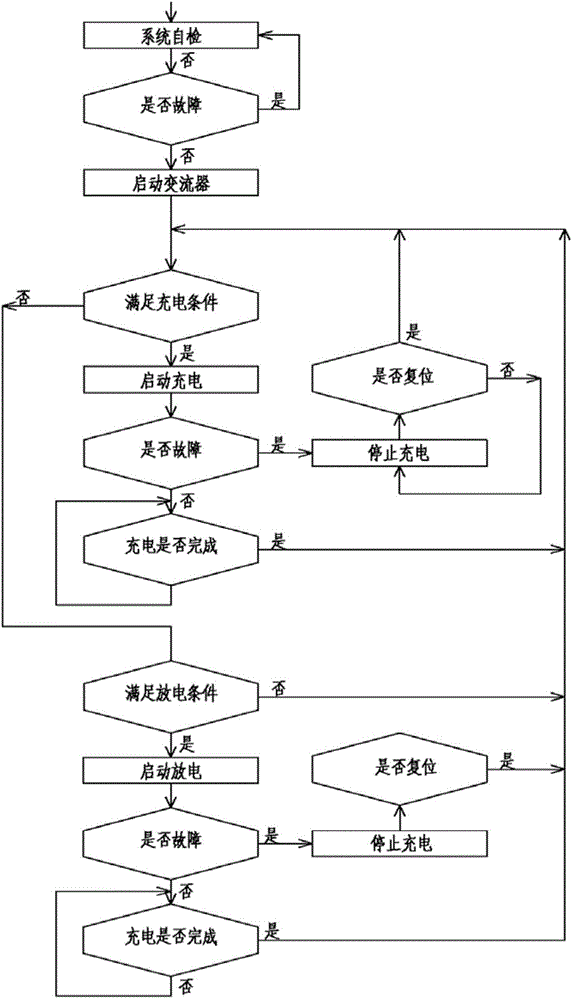

Energy storage device applied to workover rig

InactiveCN104104152AEfficient storageSave fuelElectrical storage systemAc network load balancingCapacitanceInformation processing

The invention relates to an energy storage device applied to a workover rig. The energy storage device comprises energy storage equipment, energy storage monitoring equipment and a two-way DC / DC (Direct Current / Direct Current) converter, wherein the energy storage equipment is connected with the energy storage monitoring equipment and the two-way DC / DC converter respectively; the energy storage monitoring equipment is connected with the two-way DC / DC converter; the two-way DC / DC converter is connected with a DC bus side of a frequency converter and the energy storage equipment respectively; the DC bus side of the frequency converter is connected with a motor, the energy storage monitoring equipment and the two-way DC / DC converter respectively; the energy storage equipment comprises a supercapacitor bank; and the energy storage monitoring equipment comprises a DSP (Digital Signal Processor) circuit, a high-voltage side current and voltage acquisition unit, a low-voltage side current and voltage acquisition unit, A / D (Analog to Digital) conversion circuits, a CMS (Content Management System) capacitance information processing unit, an IGBT (Insulated Gate Bipolar Transistor) driving circuit, a display screen and an alarm circuit. The energy storage device can judge a load and the power supply capacity under the current operation condition in real time, charges the energy storage equipment by fully using deceleration and lowering stages during an operation course, and improves the operation efficiency.

Owner:BEIJING CHNDRIVE ELECTRIC TECH

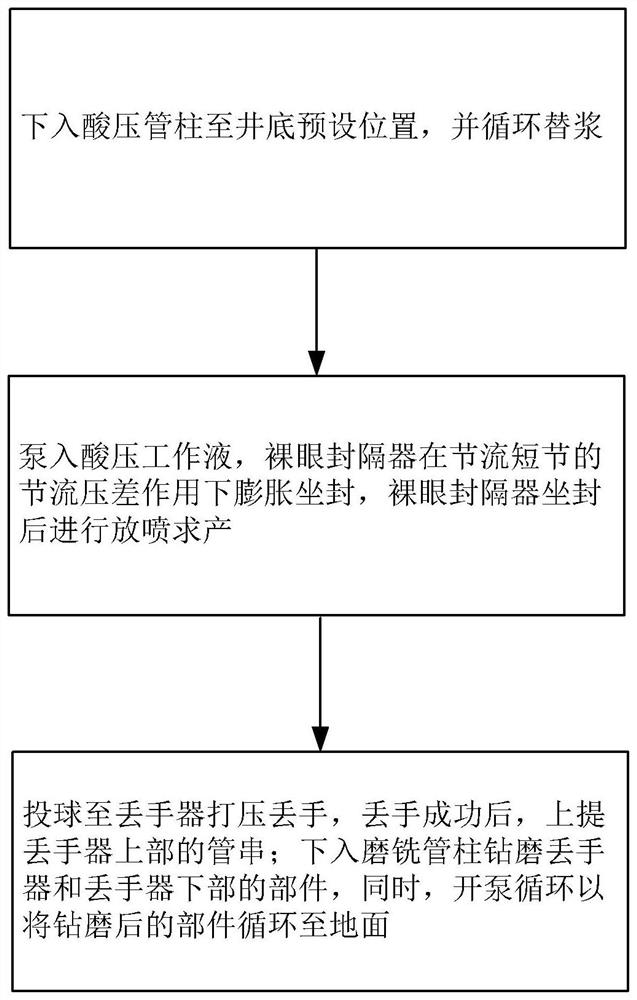

Open hole packer, acid fracturing tubular column and open hole acid fracturing method

PendingCN114427371AImprove support strengthIncrease anchoring forceFluid removalSealing/packingAcid fracturingSlurry

The invention provides an open hole packer, an acid fracturing pipe column and an open hole acid fracturing method. The open hole packer comprises a central pipe, a sealing and pressing rubber sleeve, an anchoring part and an unsealing part. The sealing and pressing rubber sleeve comprises an inner rubber sleeve, a rigid supporting sleeve and an outer rubber sleeve. The anchoring part and the deblocking part are connected to the two ends of the rigid supporting sleeve; the anchoring part of the anchoring component wraps the outer side of the end of the outer rubber barrel, and the unsealing component abuts against one end of the outer rubber barrel. The acid fracturing pipe column comprises a telescopic pipe, a hydraulic anchor, a releasing device, a throttling nipple, a guide shoe and the open hole packer, wherein the releasing device, the open hole packer, the throttling nipple and the guide shoe are all aluminum alloy components. The open hole acid fracturing method comprises the steps that an acid fracturing pipe column is put down, and slurry is cyclically replaced; setting an open hole packer for open flow production; releasing by a releasing device, and lifting a pipe string at the upper part of the releasing device; and drilling and grinding the releasing device and components at the lower part of the releasing device, and starting the pump for circulation. The packer has the advantages that the packer loss risk is reduced, the unsealing operation is convenient, the workover operation efficiency is improved, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

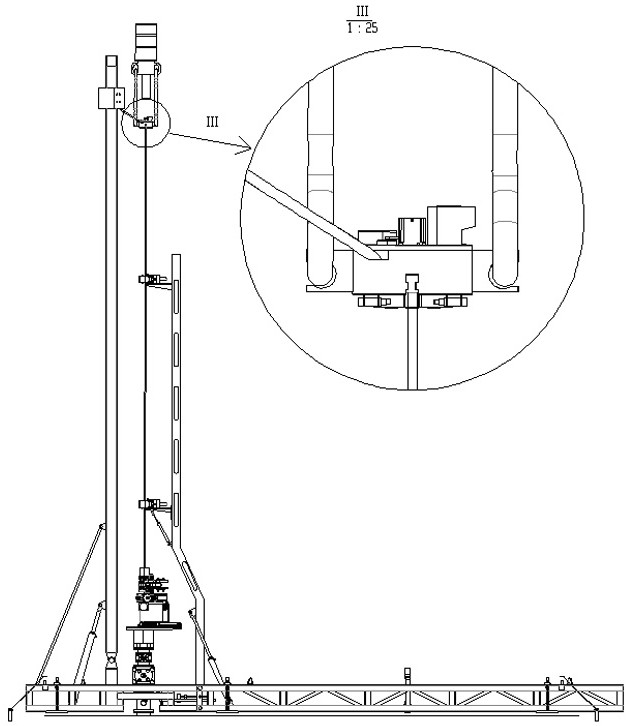

Gantry derrick allowing operation under pressure

PendingCN109488216AOvercoming liftOvercome efficiencyDrilling rodsDerricks/mastsBlock and tackleEngineering

A gantry derrick allowing operation under pressure comprises two expansion masts, a mast cross beam, a walking large hook, a large fixed pulley unit, a large hook hydraulic winch and a support platform; the two expansion masts are mounted on a ground vertically through support legs; the upper ends of the two expansion masts are connected through the mast cross beam; the lower ends of the expansionmasts are fixed together through a connection seat; the large fixed pulley unit is mounted on the mast cross beam; the support platform is fixed between the two expansion masts; the large hook hydraulic winch is mounted on the support platform; a wire rope of the large hook hydraulic winch is wound around the large fixed pulley unit and connected with the walking large hook. The gantry derrick with the walking large hook has great lifting force and is convenient to operate, so that workover time is effectively shortened. The defect that existing derricks for operation under pressure have lifting force and working efficiency problems is overcome; the gantry derrick is suitable for the under-pressure workover operation for water wells, oil wells and gas wells having various depths, workoverefficiency can be improved, and consumption of manpower and material sources is reduced.

Owner:韩咏利

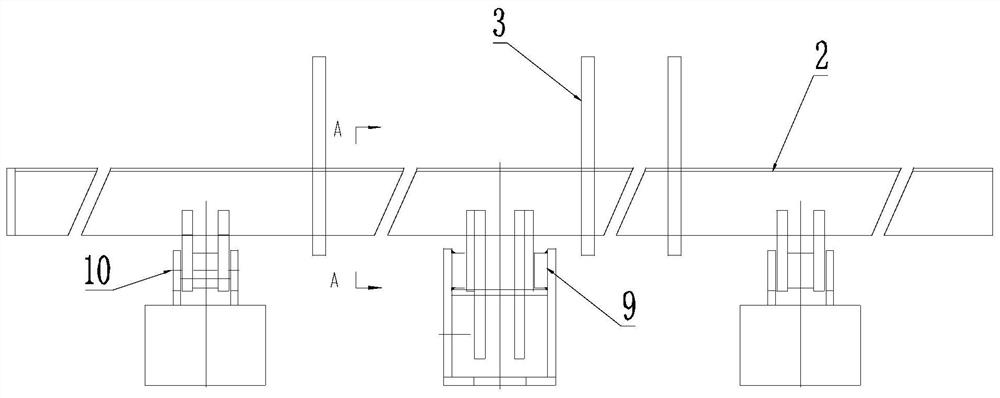

External power pipe rod conveyor

PendingCN112412363AVersatileMeet the use requirementsDrilling rodsDrilling casingsCouplingControl system

The invention provides an external power pipe rod conveyor, and relates to the technical field of oil field workover devices. The external power pipe rod conveyor comprises a rack, a hoisting mechanism, a telescopic mechanism, a turnover mechanism and a hydraulic system, wherein at least one side of the rack is provided with a feeding mechanism; the hoisting mechanism is arranged on the rack; thetelescopic mechanism is arranged on the hoisting mechanism; the turnover mechanism is arranged on the telescopic mechanism, the telescopic mechanism is used for driving the turnover mechanism to move,and the turnover mechanism is used for turning over towards one side of the rack; and the hydraulic system comprises a hydraulic quick coupling used for communicating with a hydraulic loop of an external hydraulic source, a flow control system used for controlling the flow of hydraulic oil in the hydraulic system, a high-pressure filter used for filtering the hydraulic oil in the hydraulic systemand a hydraulic valve set used for controlling all the mechanisms to act. Due to the arrangement, the external power pipe rod conveyor can be used in a well site with an electric hydraulic pump station, can also be used in a well site with a vehicle-mounted hydraulic power source when the electric hydraulic pump station cannot be powered on, and can meet the use requirements of any well site.

Owner:山东泽元石油机械有限公司

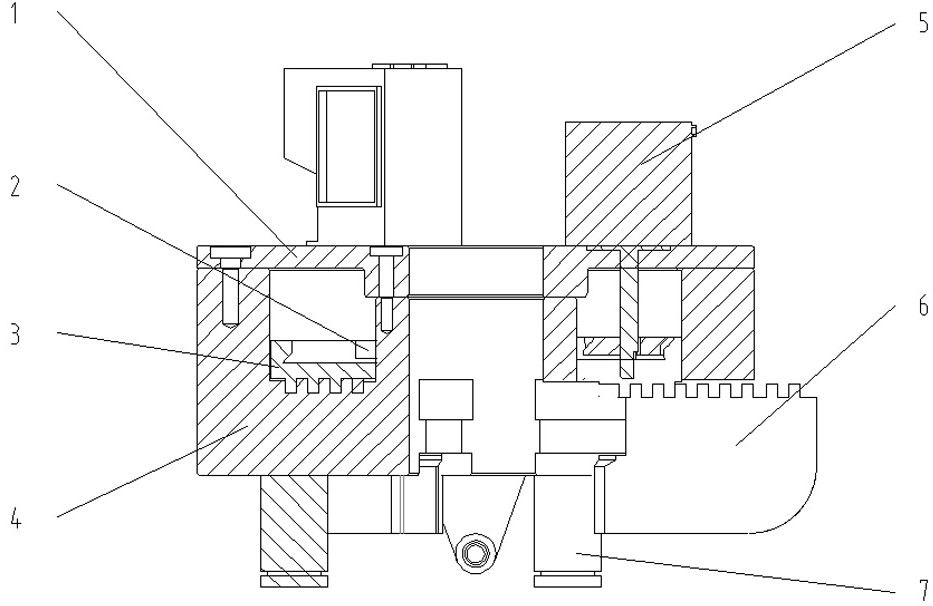

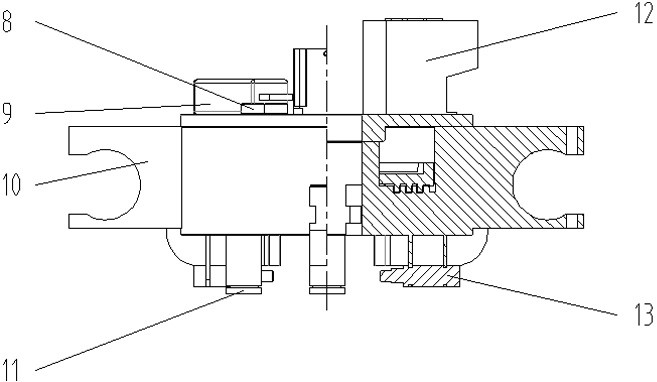

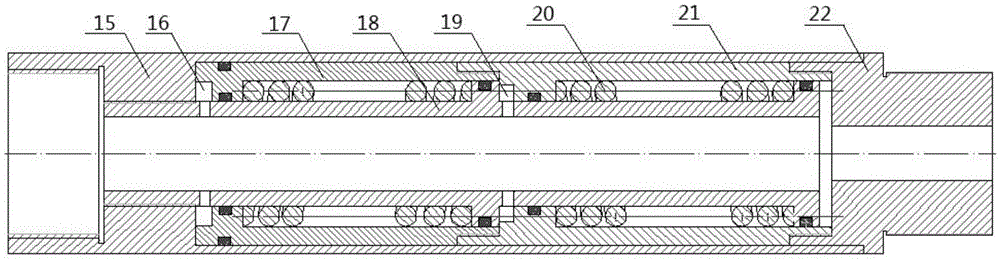

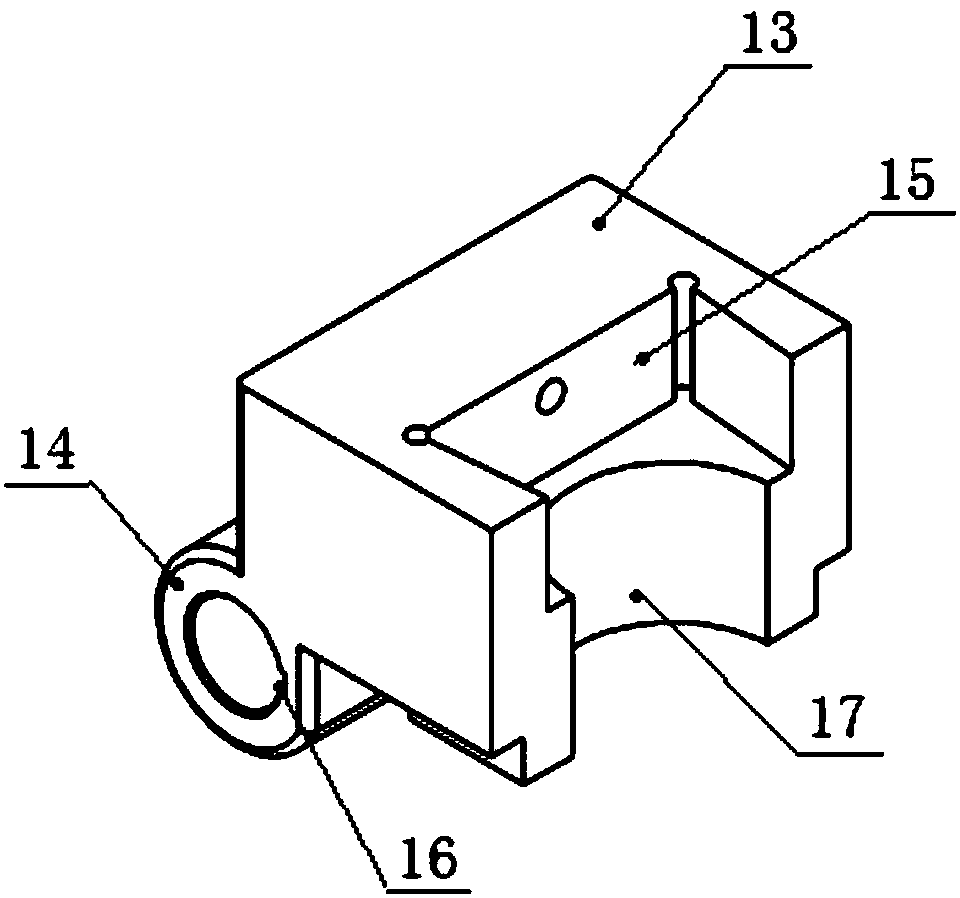

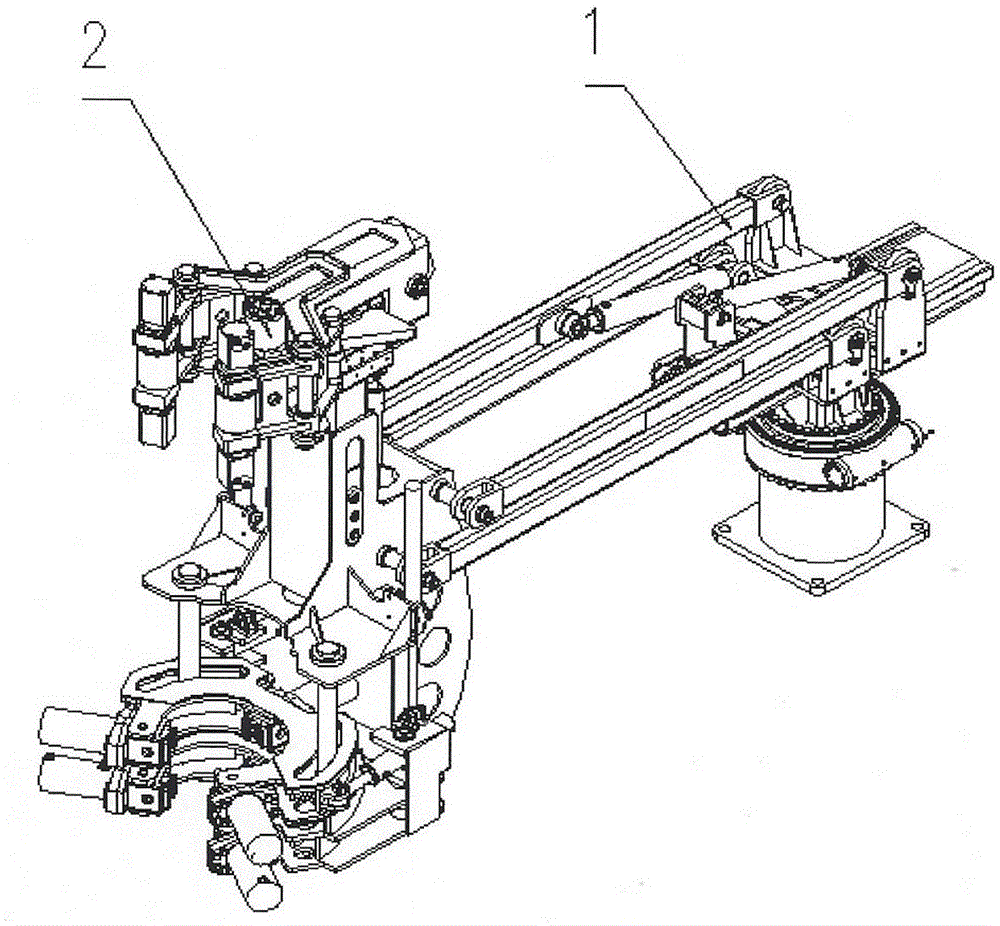

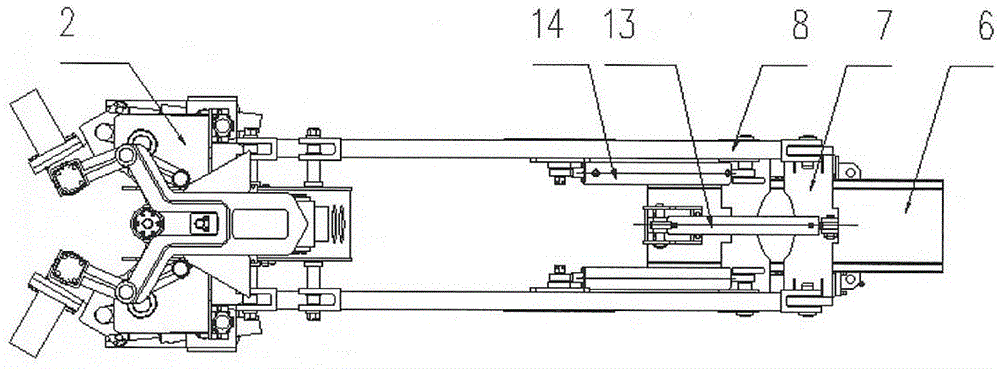

an iron driller

InactiveCN103132931BHigh degree of automationImprove securityDrilling rodsDrilling casingsRoughneckAutomation

The invention discloses an iron driller. The iron driller comprises a rotating translational stretching mechanism and a tongs assembly. The tongs assembly is composed of a support, back tongs, main tongs and spinning tongs; the rotating translational stretching mechanism is composed of a base, a rotating device, a translation device and a support arm assembly; one end of the support arm assembly is connected with the support and the other end of the support arm assembly is connected with the translation device which is connected with the base through the rotating device; the main tongs, the back tongs and the spinning tongs are connected with the support; the main tongs positioned above the back tongs are hinged to the back tongs; and the spinning tongs are mounted above the main tongs and the back tongs. By the aid of the iron driller, the automation of the overall process of attaching and detaching drilling tools is achieved, the automation level of drilling and repairing wells is improved, and the working efficiency and security are improved.

Owner:JILIN UNIV

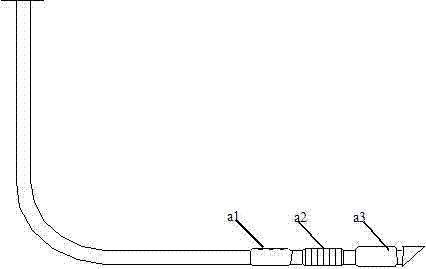

A self-adaptive intelligent retractable wellbore sand scraping tool suitable for complex structure wellbore

ActiveCN111255415BScalable and controllableControllable telescopic lengthCleaning apparatusBlade plateRotary valve

The invention relates to a self-adaptive intelligent telescopic wellbore sand scraping tool suitable for wellbore with complex structures, which mainly consists of a casing, wedge body 1, wedge body 2, knife plate, center column, two kinds of tension springs, lower joint, shunt Composed of cylinder, rotary valve plate, sensing device, etc., it is characterized in that: the knife plate has a spring groove and a wedge-shaped body two movement channels, and is fixed in the shell, and the center column inside the shell is equipped with a wedge-shaped The body is connected with a spring together; the lower joint is connected with the shell, and a shunt cylinder, a rotary valve plate, a base, a motor and a sensor are installed inside. With the help of the controllable telescopic knife plate and the intelligent feedback system, the present invention effectively avoids the practical problem of over-scraping the casing when the well bends, effectively improves the efficiency of the workover, prolongs the service life of the scraper, and reduces the risk and cost of the workover and loss.

Owner:SOUTHWEST PETROLEUM UNIV

Centralizing string and restoring string for horizontal well casing pipe dislocation and restoring process of centralizing string and restoring string

ActiveCN102852478BChange the unfavorable situationWith secondary pressure functionBorehole/well accessoriesHorizontal wellsOil field

The invention discloses a centralizing string and a restoring string for horizontal well casing pipe dislocation and a restoring process of the centralizing string and the restoring string so as to solve the problem that existing dislocation wells with the casing pipe dislocation and inner diameter coincidence degree ranging from 30-50% in an oil field are incapable of being centralized and restored. The centralizing string comprises a booster, a hydraulic anchor and an oil pipe, and an eccentricity centralizing hanger, the booster and the hydraulic anchor are sequentially connected through the oil pipe. The restoring string matched with the centralizing string in use comprises an oil pipe and a casing pipe restoring tool which are connected, an insertion pipe is connected at the bottom of a cylinder of the casing pipe restoring tool, and a casing pipe is inserted into an outer positioning cylinder of the eccentricity centralizing hanger. The restoring process is particularly applicable to thermal recovery horizontal well casing pipe dislocation restoring works and similarly applicable to other casing pipe dislocation horizontal wells. The centralizing string and the restoring string and the restoring process can be used for effectively restoring the dislocation casing pipe at a horizontal segment of the horizontal well, have no chemical pollution to an oil layer and are wide in application range, simple in construction steps and capable of effectively reducing production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drill floor well repairing machine without manual operation in well mouth

InactiveCN100491691CReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Special eccentric correcting hanger for casing fracture horizontal workover sleeve

InactiveCN102852479BThe overall structure is simple and reliableSolve the problem that the fault well cannot be correctedBorehole/well accessoriesHorizontal wellsStructural engineering

The invention provides a special eccentric correcting hanger for a casing fracture horizontal workover sleeve, which solves the difficulty that the traditional fractured well with front casing fracture internal diameter coincidence degree of 30-50% in an oil field cannot be corrected. The special eccentric correcting hanger for the casing fracture horizontal workover sleeve comprises a guide head, a hydraulic anchoring hanging device and an eccentric locating and correcting device, which are connected with one another by conversion joints, wherein the hydraulic anchoring hanging device comprises a seat seal locating mechanism and an inserted unsealing mechanism; the seat seal locating mechanism is mounted in the inserted unsealing mechanism and connected by a limiting pin; a counterweight mounting vertical slot is fixedly formed in an inner circle of a circumferential limiting inner cylinder of the eccentric locating and correcting device; a counterweight strip is mounted in the counterweight mounting vertical slot; and the lower end of the counterweight strip is connected with the guide head. After being put into a horizontal well section, one side of the special eccentric correcting hanger mounted with the counterweight strip is always positioned on downside, so that the bottom tip of the guide head can be accurately inserted into a lower casing of the fracture together with the special eccentric correcting hanger according to a preliminary determined casing fracture direction, a restoring passage of the fractured casing is broken through and the production is made again after restoring.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com