an iron driller

A technology of iron drillers and back tongs, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve the problem that the safety of operators cannot be effectively guaranteed, the connection, disassembly and maintenance of drilling tools are inconvenient, and the connection and disassembly of drilling tools The problem of slow speed and other problems is achieved, which is beneficial to maintenance, fast in make-up and break-out speed, and less damage to the drill pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

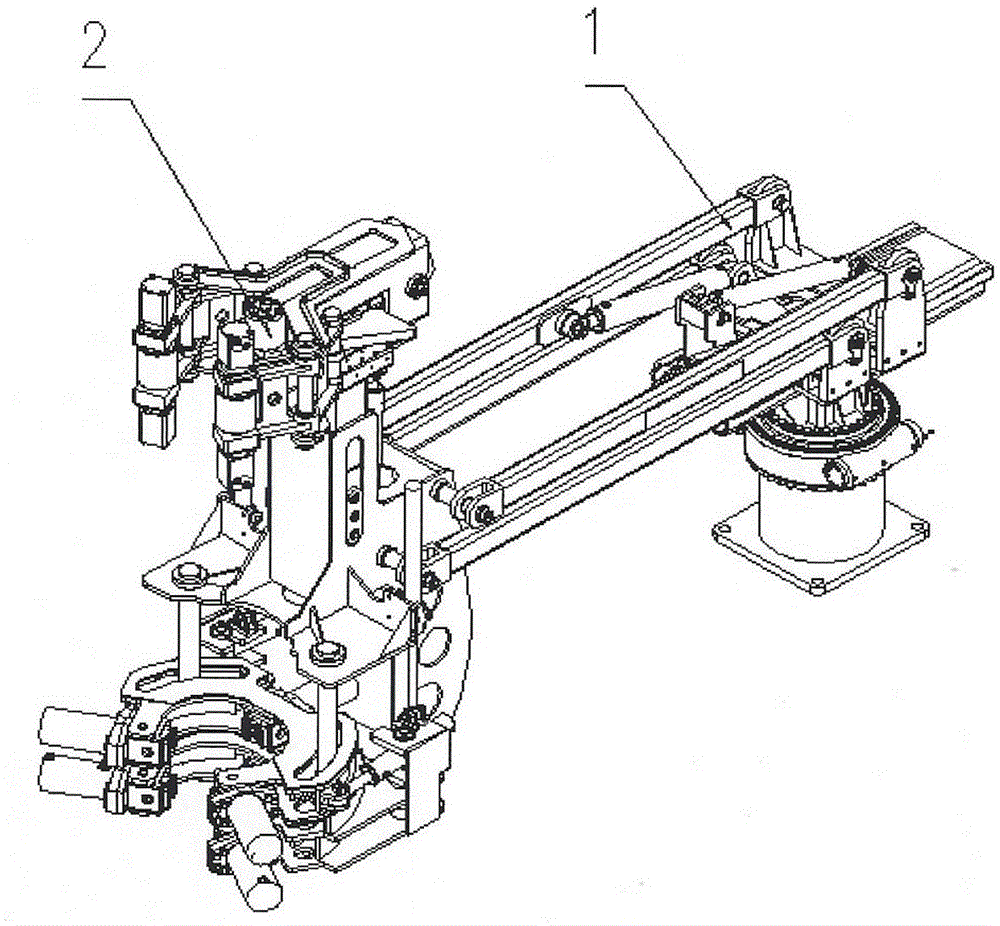

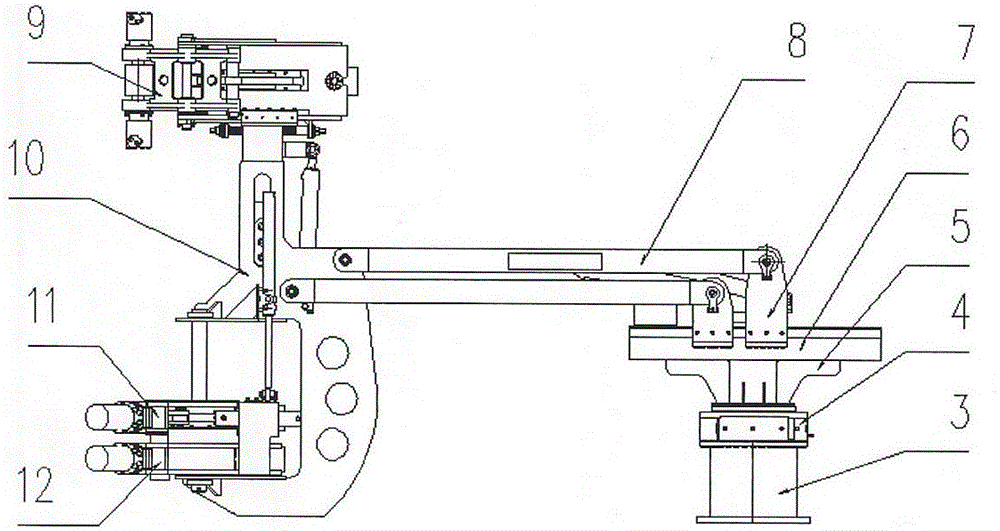

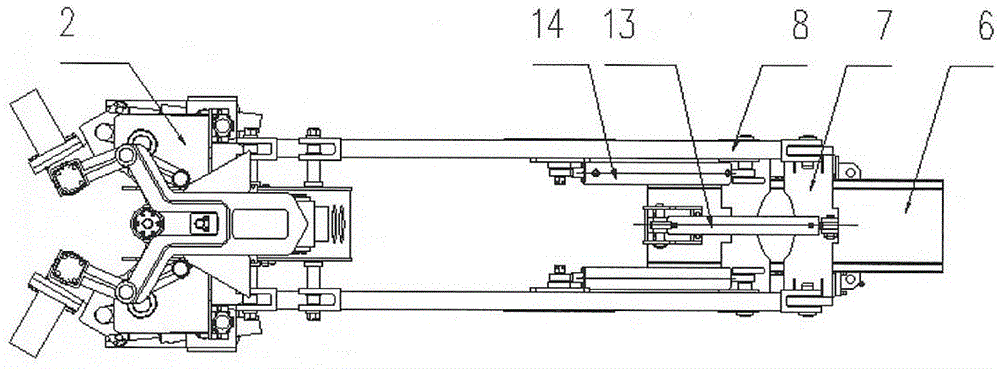

[0030] see figure 1 , figure 2 and image 3As shown, this embodiment is composed of a rotary and translational extension mechanism 1 and a pliers body assembly 2. The pliers body assembly 2 is composed of a bracket 10, a back tong 12, a main tongs 11 and a turnbuckle pliers 9, and the rotation and translational extension Mechanism 1 is composed of base 3, rotary device 4, support mechanism 5, translation device, parallel four-bar linkage mechanism formed by extension pull rod 8 and extension drive cylinder 14; translation device is composed of translation guide rail 6, translation block body 7 and The translation drive oil cylinder 13 is composed of,

[0031] One end of the parallelogram mechanism composed of extension rods 8 is hinged on the bracket 10 and the other end is hingedly connected to the translation device, and the translation device is connected to the base 3 through the rotary device 4; 9 is connected to the bracket 10, the main tongs 11 are located above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com