Well repair well mouth unmanned operation platform

A work platform and workover technology, which is applied to wellbore/well components, drilling equipment, earthwork drilling and production, etc., can solve the problems of serious environmental pollution, high risk of safe operation, high labor intensity, etc., achieve good repeatability, repair The effect of high well efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

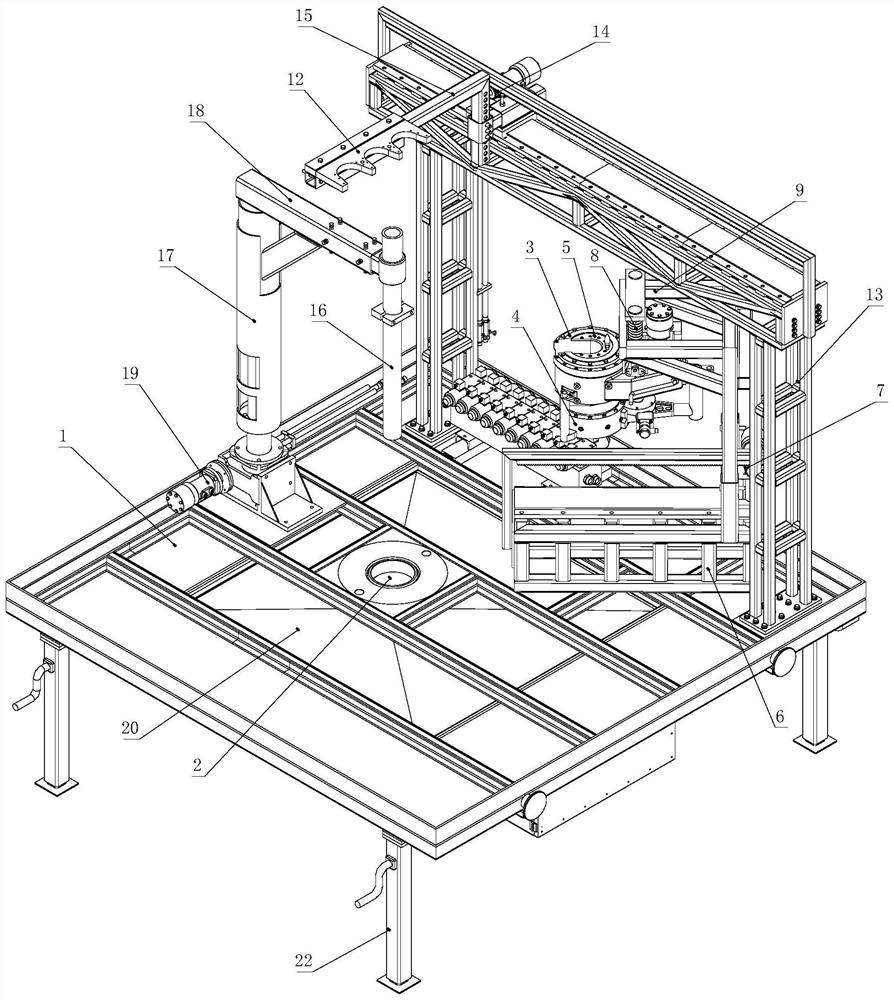

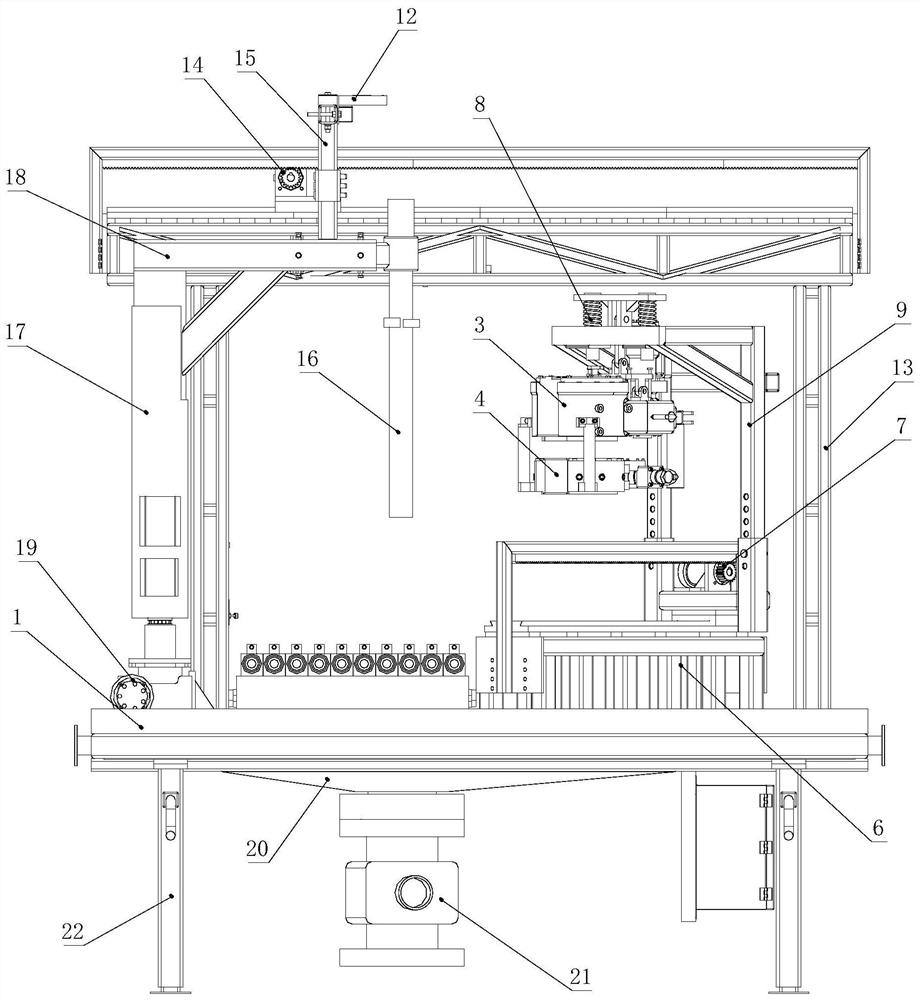

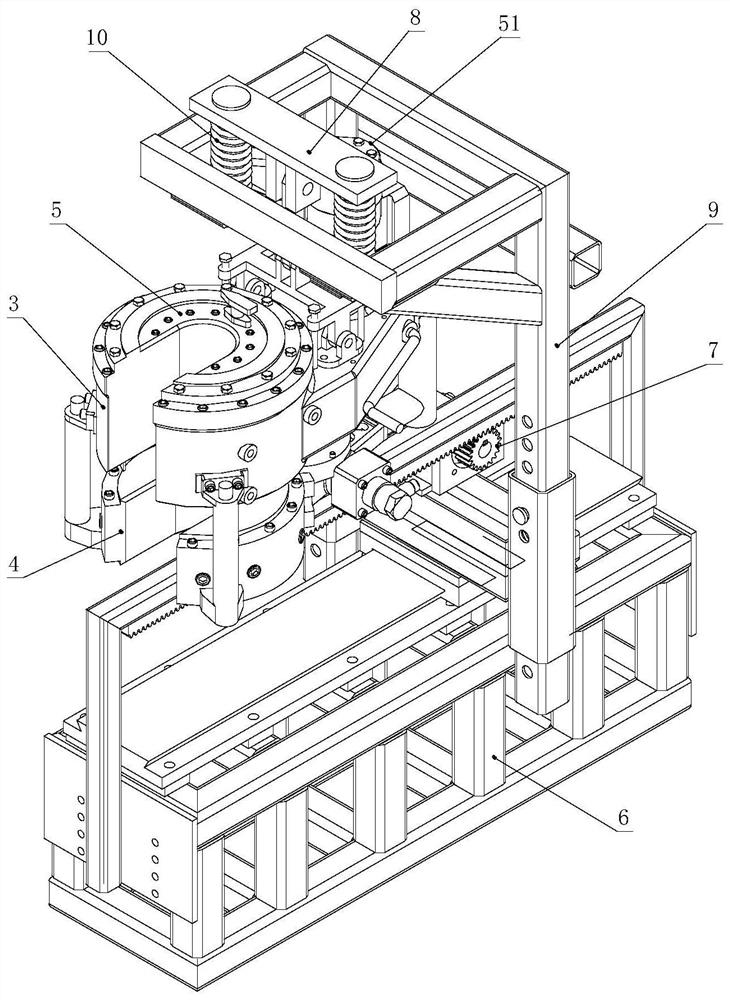

[0034] An unmanned operation platform for workover and wellhead, including a workbench 1, a flange 2 is provided in the middle of the workbench 1 for pipe rods to pass through; the workbench 1 is also provided with a hydraulic tong assembly and a push pipe assembly, The hydraulic pliers assembly is used to disassemble and connect pipe rods, the hydraulic pliers of the hydraulic pliers assembly can move radially along the flange 2 , and the pipe push assembly is used to push the pipe rods away from the workbench 1 .

[0035] As a specific embodiment of the hydraulic tongs, the hydraulic tongs include a main tong 3 and a back tong 4. The main tongs 3 are driven by a hydraulic motor 51 to rotate the main tongs, so that the back tongs 4 can hold the female end of the pipe buckle, the main tongs, and the main tongs. The pliers 3 clamp the male buckle end of the pipe buckle, and then the main tongs 3 are driven to rotate by the hydraulic motor 51, so that the male buckle end and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com