Pigging and pipe scraping integrated tool

A technology for drilling wells and tools, which is applied in the field of integrated tools for drilling and scraping pipes, which can solve the problems of wear, labor and time-consuming pipe strings, etc., and achieve the effects of reducing maintenance costs, saving energy, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

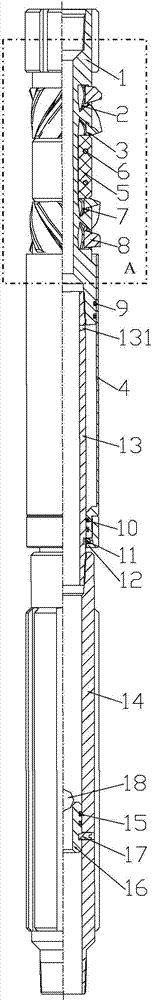

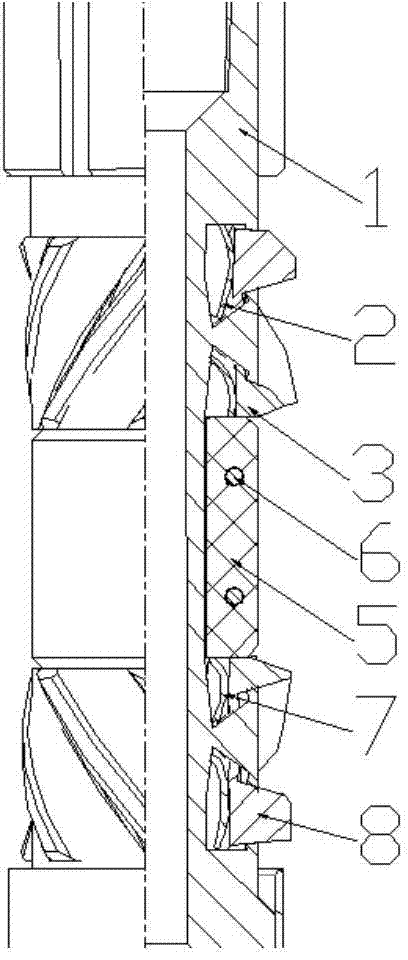

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

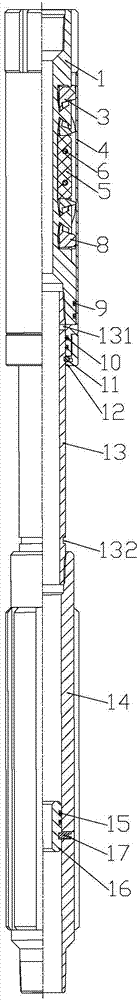

[0023] Such as Figure 1 to Figure 3 As shown, the present invention proposes an integrated tool for drilling and scraping pipes, which includes a scraping mechanism and a drilling mechanism that are fixedly connected sequentially from top to bottom. A knife groove is provided, and the scraping mechanism also includes a scraping knife inserted into the knife groove, and a reed for resetting the scraping knife is arranged in the knife groove; the scraping mechanism also includes a The sleeve 4 of the scraper is sleeved outside the main body 1 of the knife holder, and the sleeve 4 can move up or down until the scraper stretches out under the elastic force of the reed.

[0024] In the process of the integrated tool for drilling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com