A one-pass pipe string layered water injection sand control backwashing device and a method

A technology of layered water injection and backwashing device, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of increased risk, small diameter of well retention, and increased workover cost, so as to reduce the later stage. Operation risk, simple process operation method, and effect of improving workover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

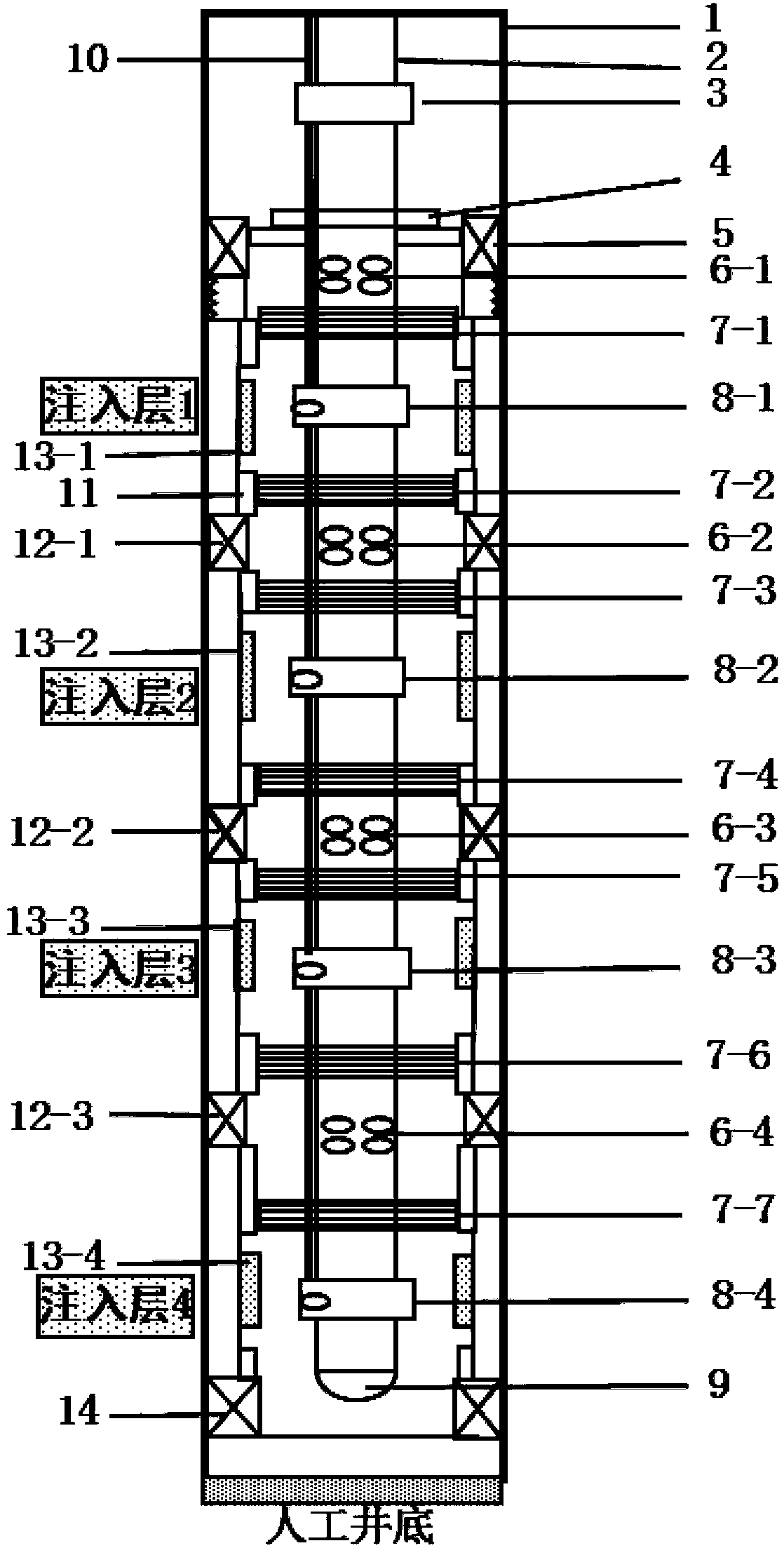

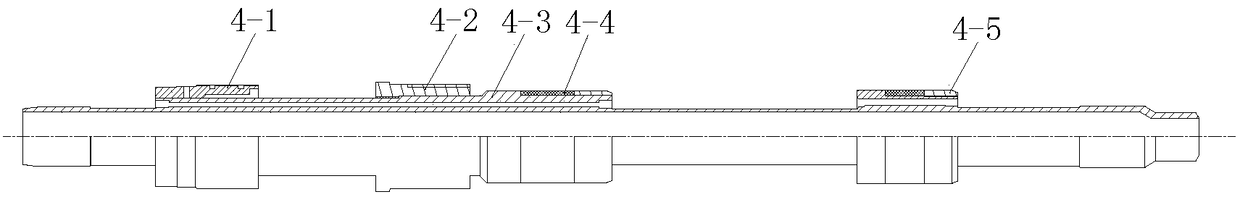

[0027] as attached figure 1 As shown, a one-pass layered water injection and sand control backwashing device has three functions of layered water injection, independent screen sand control and backwash well. The multi-functional combined string is lowered to the design well depth. It includes the oil layer casing 1 inserted into the first injection layer, the second injection layer, the third injection layer and the fourth injection layer in sequence, and the oil layer casing 1 is provided with two layers of strings: the inner layer is set and tested The integrated pipe string for sealing, water injection and backwashing has the function of water injection and is compatible with the function of backwashing wells; the outer layer of sand cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com