Automatic elevator for sucker rod in oilfield workover operation and use method

A technology of sucker rods and elevators, which is applied to drill pipes, drilling equipment, earthwork drilling and production, etc. It can solve the problems of unmanned and automated wellhead operations, difficulty in finding elevators, etc., and improve the efficiency of workover operations , Reduce labor intensity and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

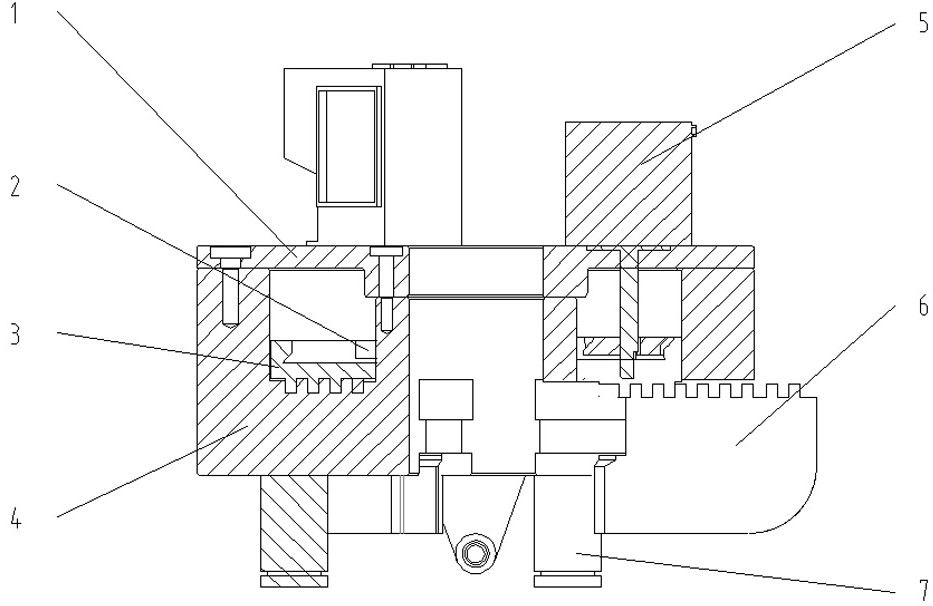

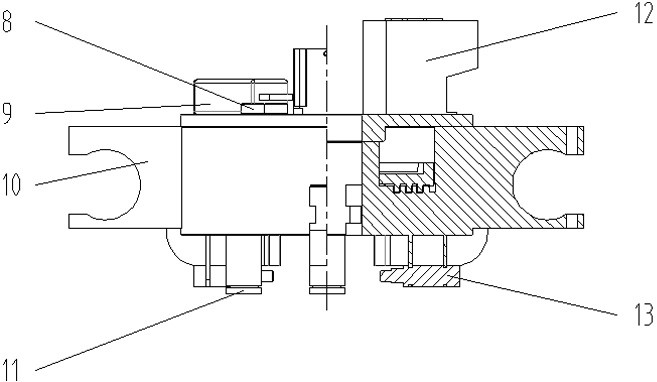

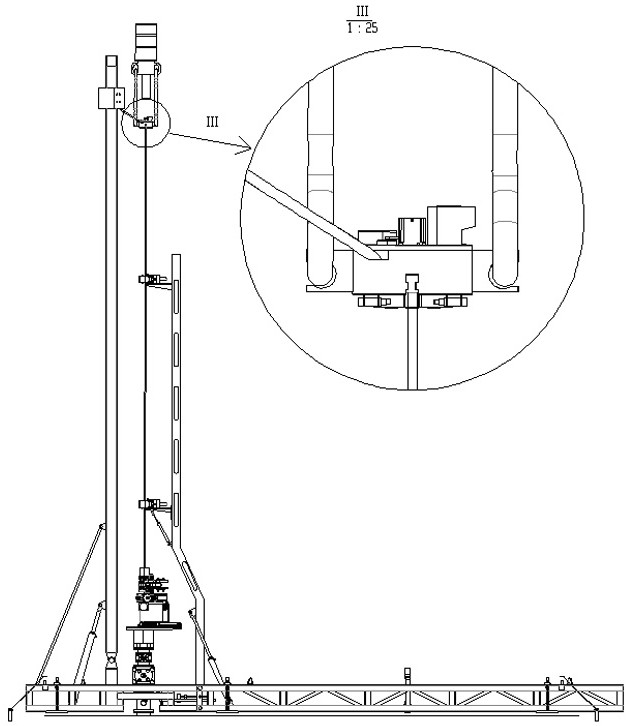

[0027] Embodiment 1, with reference to Figure 1-2 , an automatic sucker rod elevator for oil field workover operations mentioned in the present invention, including an elevator end cover 1, a small helical gear 2, a large bevel gear 3, an elevator box 4, a stepping motor 5, and claws 6 , adjustable support 7, DC power supply 8, stepper motor controller 9, hook 10, position sensor 11, stepper motor driver 12, inductive sensor 13, described stepper motor 5, DC power supply 8, large umbrella The gear 3, the small helical gear 2, and the claw 6 form the transmission actuator. The upper part of the large bevel gear 3 meshes with the small helical gear 2, and the lower part drives the claw 6 through the flat thread of the coil wire. The stepping motor 5 passes through the small helical gear 2, the large The bevel gear 3 drives multiple claws 6 forward and backward; the stepper motor driver 12, the stepper motor controller 9, the position sensor 11, and the inductive sensor 13 form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com