Drill floor well repairing machine without manual operation in well mouth

A workover rig and drilling platform technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of unfavorable safety production, high labor intensity, low efficiency, etc., to improve the efficiency of workover operations, good benefits, guarantee The effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

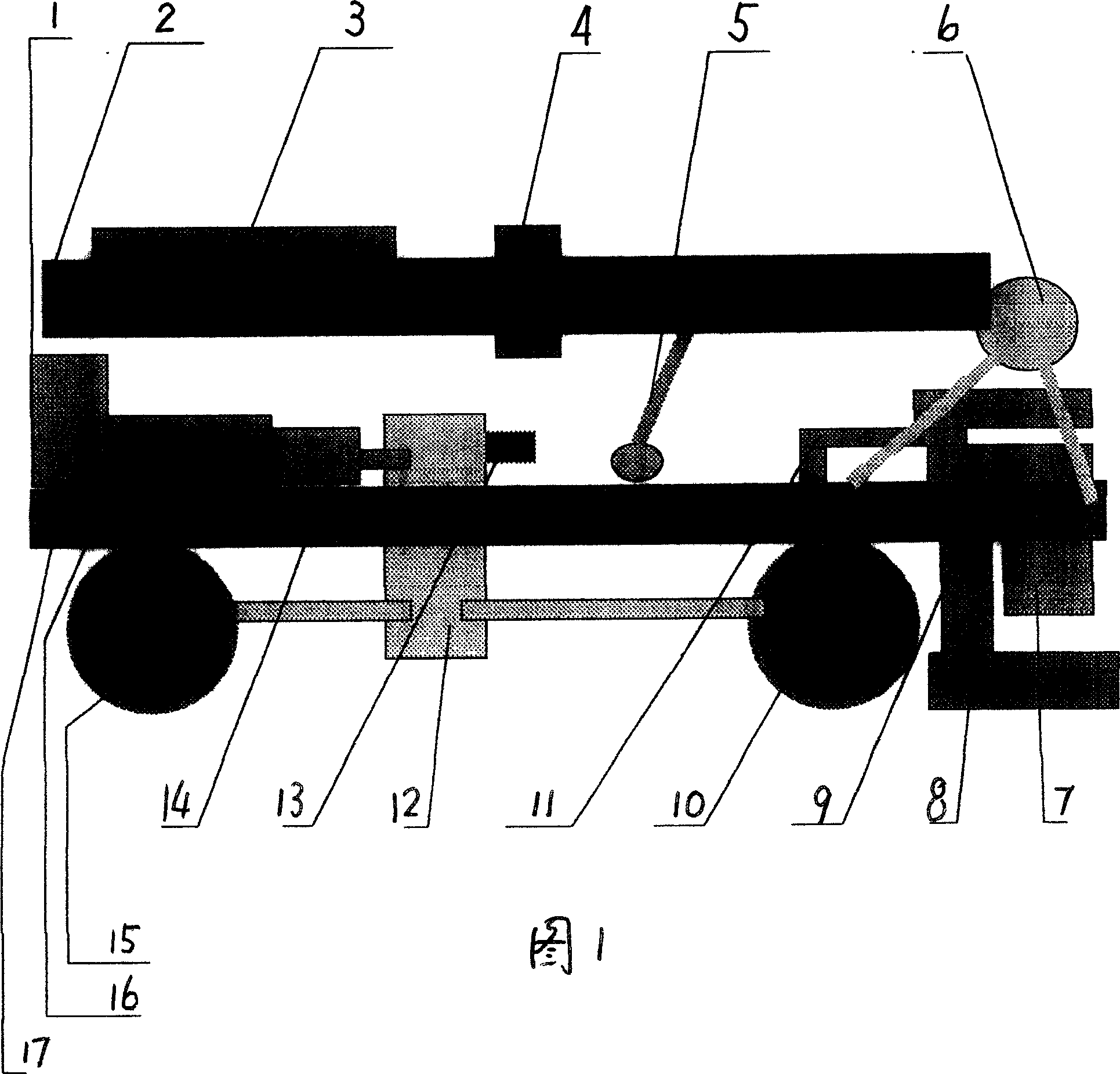

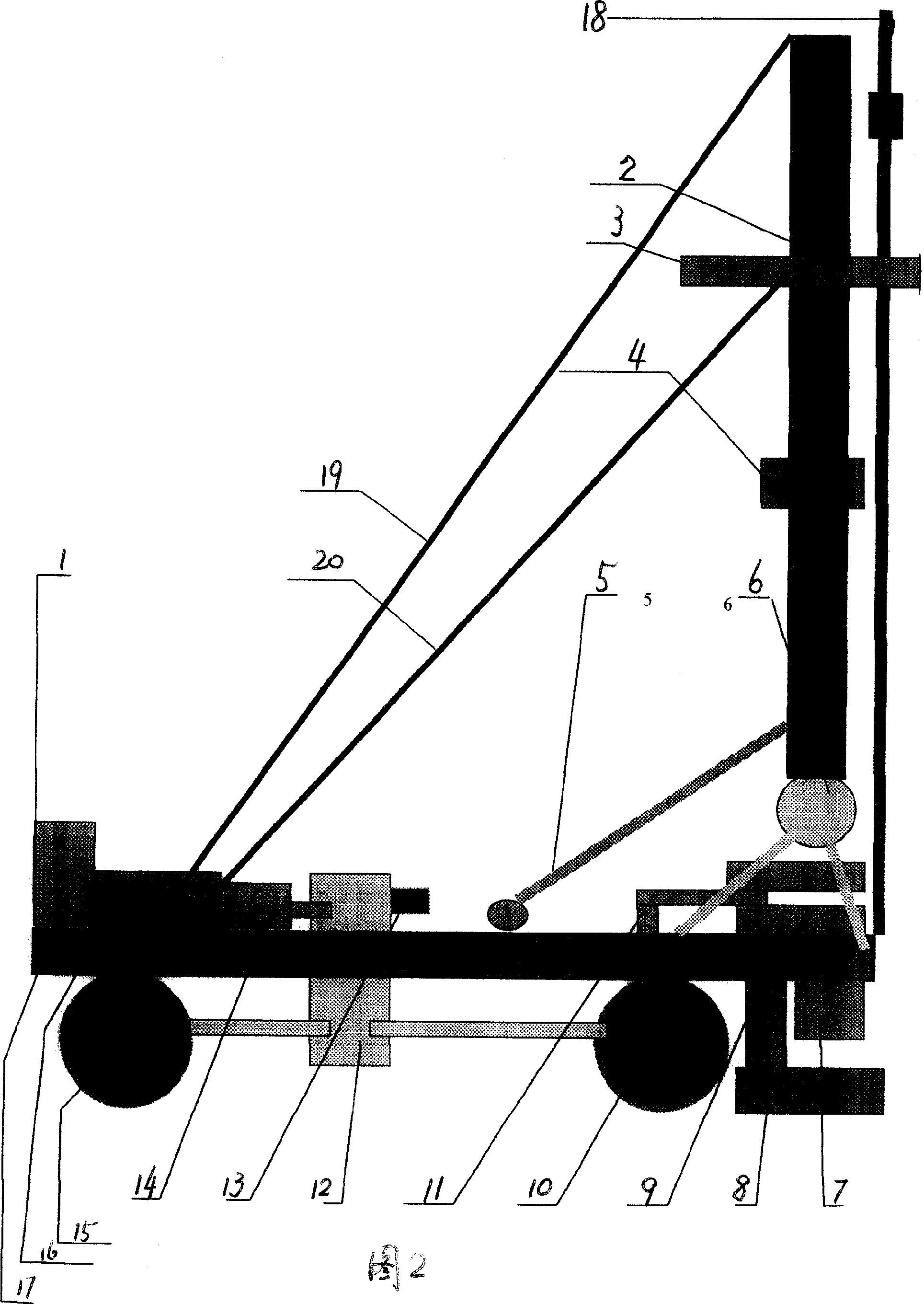

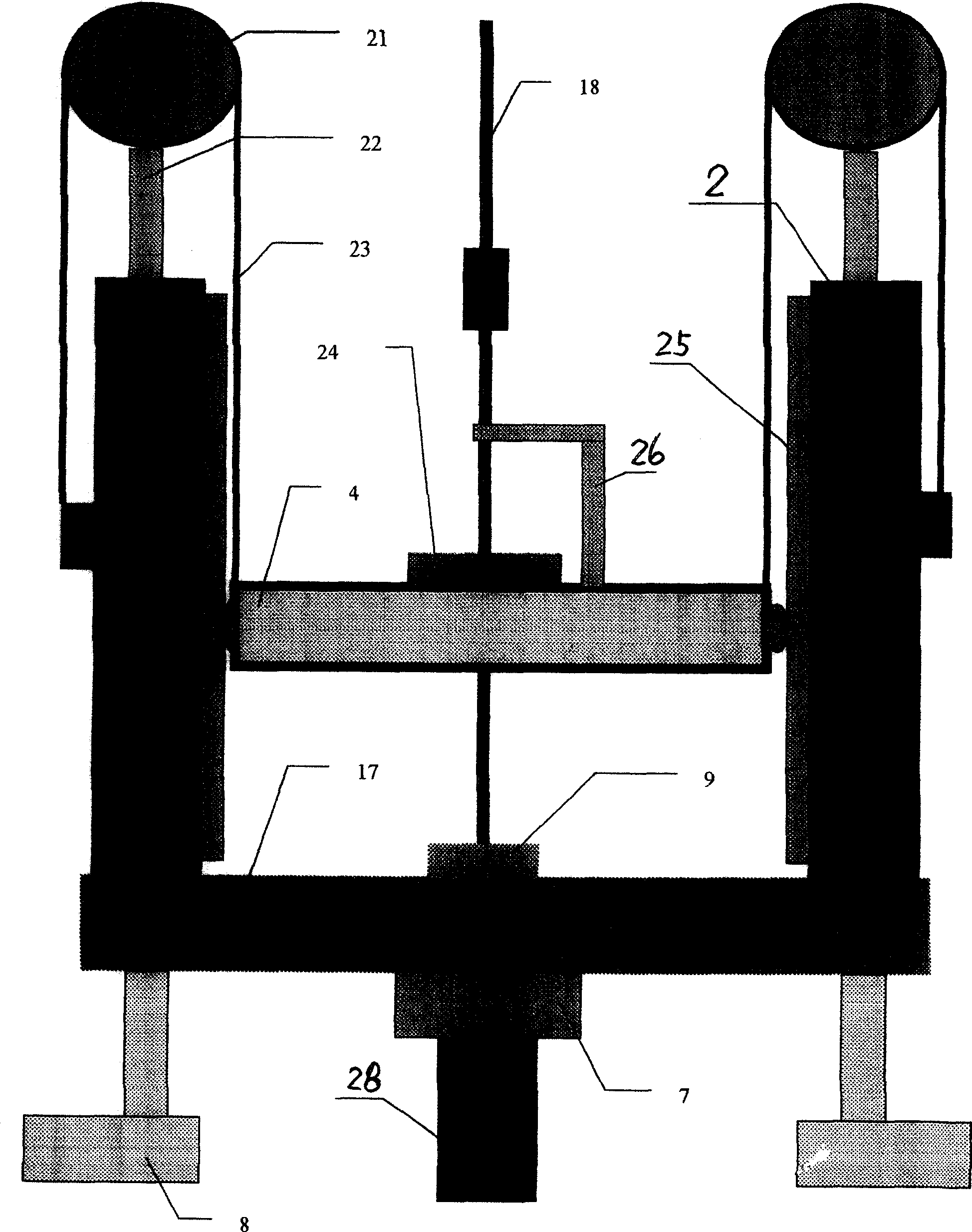

[0008] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The following will be described in conjunction with the accompanying drawings.

[0009] As shown in the figure: the present invention consists of a driving control room 1, a thick support column 2, an automatic pipe discharge device 3 with a manipulator, a lifting device 4, a luffing hydraulic cylinder 5, a support column support 6, a wellhead hydraulic blowout preventer 7, Drill floor hydraulic support 8, fixed hydraulic chuck 9, rear tire and rear drive axle 10, hydraulic clamp with telescopic slideway 11, hydraulic gearbox with 5 outputs and transmission shaft 12, high-flow high-pressure gear pump 13 , hydraulic torque converter and drive shaft 14, front tire and front drive axle 15, engine 16 and vehicle frame and drill floor 17 are formed. Its structure and assembly relationship are as follows: the front part above the vehicle frame and the drill floor 17 is sequentially provided with a driving control room 1, an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com